Microswitches and Limit Switches: Key Differences Explained

Micro switches and limit switches play an integral role in modern industrial automation and electronic equipment. Although both types of switches are used to control the opening and closing of circuits, they have significant differences in terms of working principle, application scenarios, and characteristics.

read more>

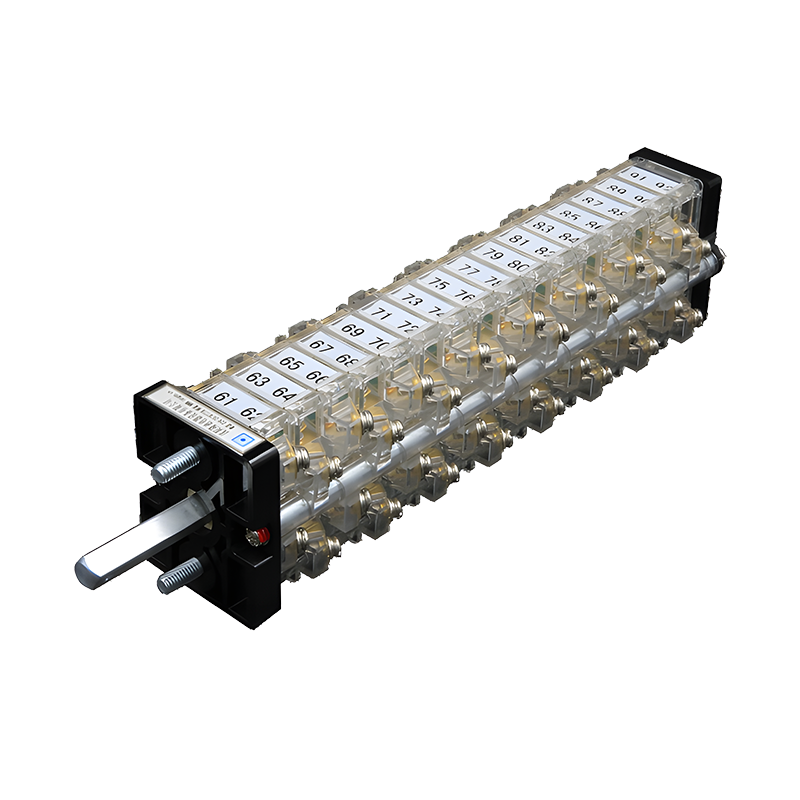

Must Know Auxiliary Switch Shopping

When it comes to shopping for auxiliary switches, there are numerous options on the market, but not all of them will meet your specific needs. When shopping for an auxiliary switch, there are a few key considerations to take into account to ensure that the product you choose not only meets quality standards, but also delivers the expected performance.

read more>

What is the treatment of auxiliary switches in case of malfunction?

Auxiliary switches play a vital role in modern industrial and domestic equipment. They not only ensure the stable operation of the system, but also provide the necessary safety in the event of a malfunction. However, even the most reliable devices can encounter problems. So, how should we react when faced with an auxiliary switch failure situation? This article will explore this topic in depth.

read more>

What is the difference between the contact materials of microswitches?

Micro switches offer a wide range of options when it comes to the selection of electrical contact materials, mainly including gold, silver and their alloys as well as gold and silver plating. These different materials exhibit their own characteristics and advantages in terms of conductivity, hardness, corrosion resistance and cost. The differences between these contact materials will be explored in detail below.

read more>

What are the contact materials for micro switches?

Micro switches, a type of switch with tiny contact intervals and a tacho mechanism, play a vital role in many electronic devices and machines. The contact material, in particular, has a profound effect on the performance of the switch. The following is a detailed discussion of micro switches contact materials and their characteristics.

read more>

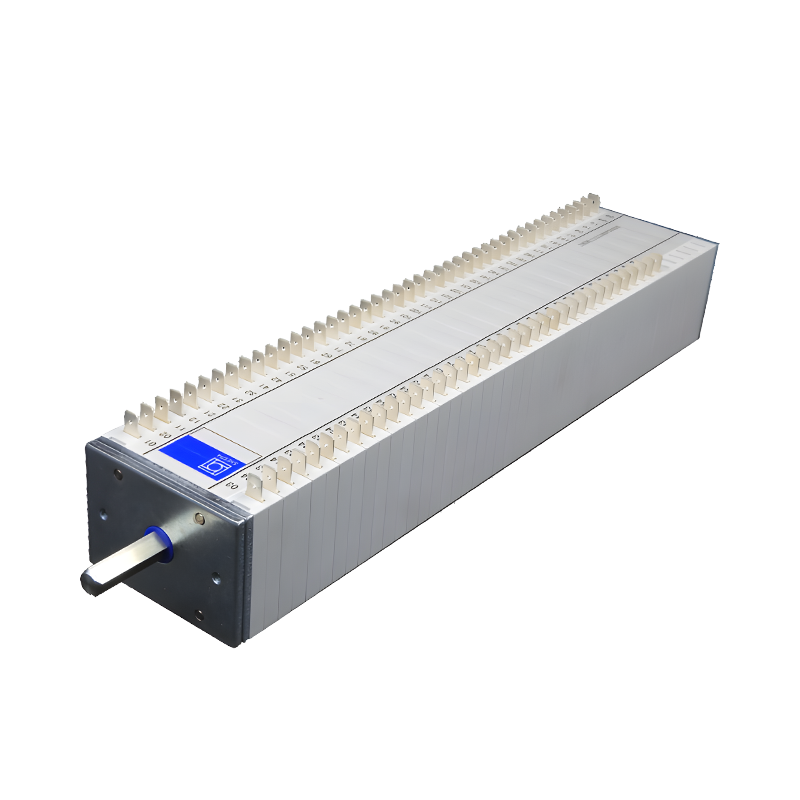

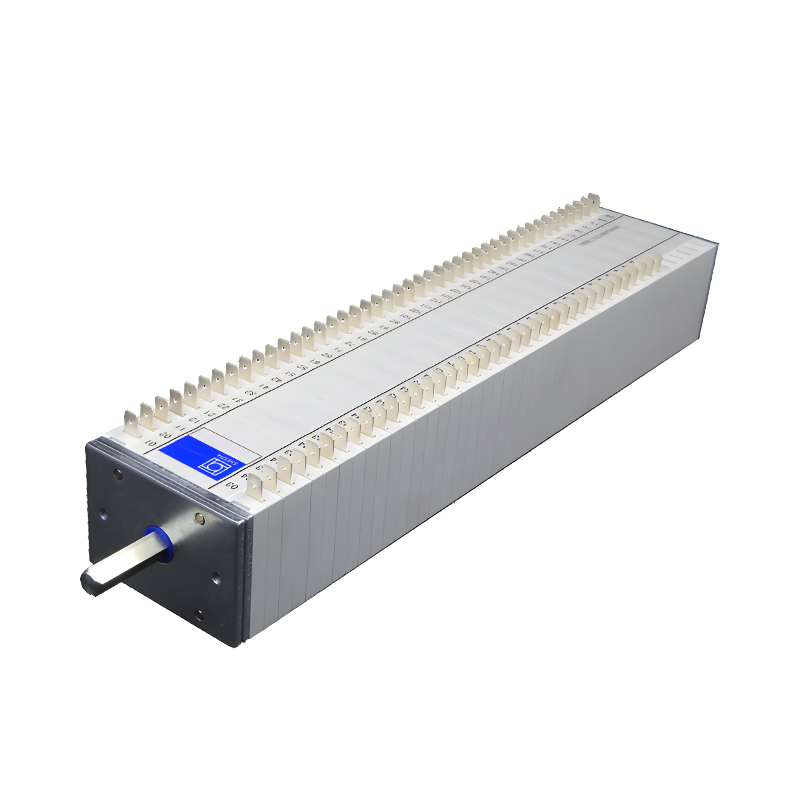

Do auxiliary switches require regular maintenance?

Auxiliary switches play a vital role in modern electrical systems. They not only ensure the safe operation of electrical circuits, but also provide essential control and protection functions. However, a common question is: Do auxiliary switches require regular maintenance?

read more>