What are the processes of auto parts processing?

Release time:2024-09-03

Auto parts are an indispensable and important part of automobile manufacturing, and its processing process plays a vital role in the quality, performance and safety of automobiles. The auto parts processing process includes blank preparation, parts processing, heat treatment, surface treatment and inspection. These processes ensure the quality and performance of automotive parts and provide a solid foundation for the entire automotive manufacturing process.

Blank preparation is the first step in the processing of auto parts. Blanks are the raw materials for automotive parts, usually including castings, forgings, sheet metal parts, etc. At this stage, the raw materials need to be inspected for quality, pre-treatment and undercutting operations. Among them, undercutting can use laser cutting, water cutting, plasma cutting and other processes to cut the raw material into the required shape and size.

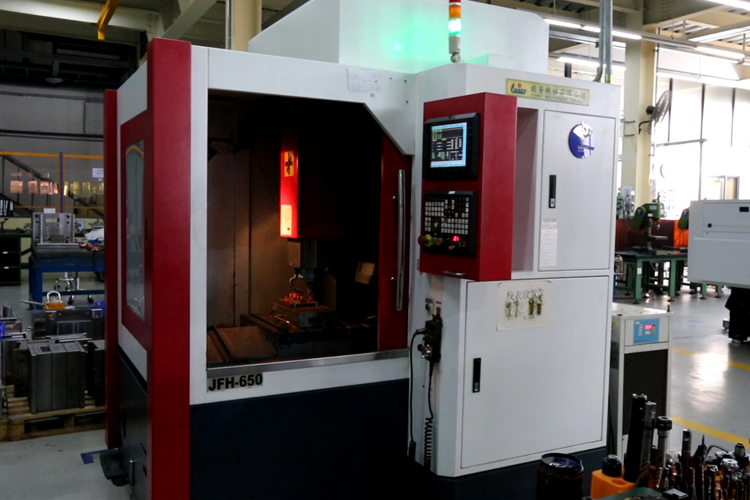

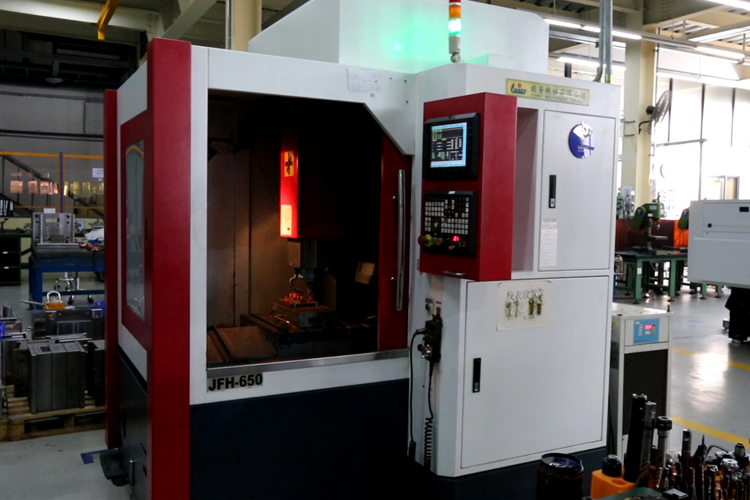

Next is the parts processing link, which is the core part of auto parts processing. It mainly includes processes such as milling, turning, drilling, reaming and grinding. These processes can remove excess material from the blank and form the desired shape and size, while ensuring machining accuracy and quality. Milling is mainly used for processing planes, steps, grooves, etc.; turning is mainly used for processing cylindrical, conical and other rotary parts; drilling and reaming are used for processing holes; grinding is used to improve the precision and surface quality of the workpiece.

Heat treatment is one of the important aspects of automotive parts processing, the main purpose is to improve the mechanical properties of the material, wear resistance, fatigue resistance and corrosion resistance. Heat treatment process includes melting, pouring, cooling and other links, which has an important impact on the quality and service life of the parts.

Surface treatment is another important link, aimed at improving the corrosion resistance, wear resistance, fatigue resistance and decorative parts. Surface treatment processes include painting, plating, oxidization treatment, etc. Painting can improve the appearance of the car quality and corrosion resistance; plating is a method of forming metal plating on the surface of the workpiece, commonly used plating layer of zinc, chromium, etc.; oxidation treatment includes bluing, phosphating, oxide film, etc., which can improve the corrosion resistance of the workpiece and decorative.

Finally, the inspection link, which is an important step to ensure the quality and safety of auto parts processing. Inspection mainly includes process inspection and finished product inspection of two links. Process inspection is mainly for the processing of semi-finished products for inspection, to ensure that the processing process does not appear quality problems; finished product inspection is the final product inspection, to ensure that the product meets the design requirements and the use of performance. The inspection process requires the use of a variety of measuring tools and instruments, such as calipers, micrometers, percentage tables, etc., to measure and compare the workpiece.

In summary, automotive parts processing process is an important part of the automobile manufacturing process, and its processing quality and efficiency directly affects the quality and performance of the car. Therefore, to strengthen the quality control and monitoring of all aspects of the automotive parts machining process, and to improve the machining accuracy and performance of the parts, is the current automobile manufacturing industry needs to focus on and solve the problem.

Blank preparation is the first step in the processing of auto parts. Blanks are the raw materials for automotive parts, usually including castings, forgings, sheet metal parts, etc. At this stage, the raw materials need to be inspected for quality, pre-treatment and undercutting operations. Among them, undercutting can use laser cutting, water cutting, plasma cutting and other processes to cut the raw material into the required shape and size.

Next is the parts processing link, which is the core part of auto parts processing. It mainly includes processes such as milling, turning, drilling, reaming and grinding. These processes can remove excess material from the blank and form the desired shape and size, while ensuring machining accuracy and quality. Milling is mainly used for processing planes, steps, grooves, etc.; turning is mainly used for processing cylindrical, conical and other rotary parts; drilling and reaming are used for processing holes; grinding is used to improve the precision and surface quality of the workpiece.

Heat treatment is one of the important aspects of automotive parts processing, the main purpose is to improve the mechanical properties of the material, wear resistance, fatigue resistance and corrosion resistance. Heat treatment process includes melting, pouring, cooling and other links, which has an important impact on the quality and service life of the parts.

Surface treatment is another important link, aimed at improving the corrosion resistance, wear resistance, fatigue resistance and decorative parts. Surface treatment processes include painting, plating, oxidization treatment, etc. Painting can improve the appearance of the car quality and corrosion resistance; plating is a method of forming metal plating on the surface of the workpiece, commonly used plating layer of zinc, chromium, etc.; oxidation treatment includes bluing, phosphating, oxide film, etc., which can improve the corrosion resistance of the workpiece and decorative.

Finally, the inspection link, which is an important step to ensure the quality and safety of auto parts processing. Inspection mainly includes process inspection and finished product inspection of two links. Process inspection is mainly for the processing of semi-finished products for inspection, to ensure that the processing process does not appear quality problems; finished product inspection is the final product inspection, to ensure that the product meets the design requirements and the use of performance. The inspection process requires the use of a variety of measuring tools and instruments, such as calipers, micrometers, percentage tables, etc., to measure and compare the workpiece.

In summary, automotive parts processing process is an important part of the automobile manufacturing process, and its processing quality and efficiency directly affects the quality and performance of the car. Therefore, to strengthen the quality control and monitoring of all aspects of the automotive parts machining process, and to improve the machining accuracy and performance of the parts, is the current automobile manufacturing industry needs to focus on and solve the problem.