An in-depth look at the working principle and application areas of limit switches

Release time:2024-09-03

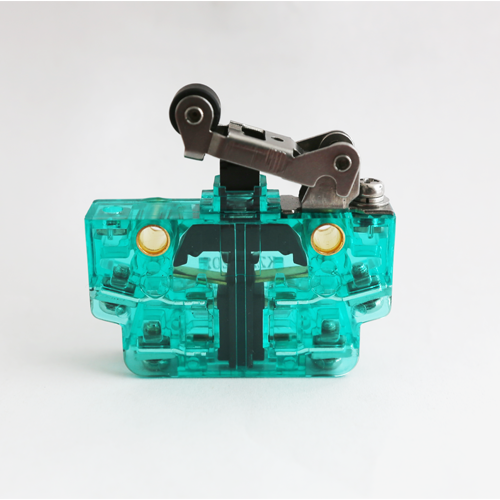

Limit switches, a small and inconspicuous device, play a vital role in industrial automation. It realizes precise control of the limit position of mechanical equipment through mechanical triggering, converts physical action into electrical signals, and further drives mechanical or protection systems to carry out corresponding operations.

Principle Analysis

In terms of working principle, limit switches achieve their function based on the interaction between mechanical trigger parts and actuating parts. When the mechanical movement reaches the set limit position, the trigger part will actuate the contact of the switch, thus changing the on/off state of the circuit. This change can either close or break the circuit, depending on the configuration of the other electrical components used in combination with the limit switch.

Types

The types of limit switches are divided into two main categories: contact and non-contact. Contact limit switches detect the presence of an object through physical contact and are commonly used in industrial production lines for simple and direct position detection. Non-contact limit switches, on the other hand, utilize magnetic, photoelectric and other technologies to sense objects without direct contact, and are suitable for scenarios that require higher accuracy and response speed.

Application Cases

In practical applications, limit switches are widely used in many fields, such as construction, harbor, mining and so on. In cranes, transmission machinery and other equipment, limit switches are used for the control and limitation of spatial coordinates to ensure the safety of equipment operation and improve efficiency. In elevator control system, limit switches undertake the tasks of controlling the speed of opening and closing the car door, automatically opening and closing the door limit, as well as protecting the upper and lower limits of the car to ensure the safety of riding.

Design selection

In the face of different types of limit switches, the design selection needs to consider the application environment, mechanical strength of the equipment, environmental adaptability and other factors. For example, when applying in high-temperature environment, high-temperature-resistant limit switches, such as YNTH series, should be selected; and in the scenes with special requirements on protection level, products with high protection performance should be selected.

Overall, although the limit switch is small, the role should not be underestimated. It is through a simple mechanical and electrical signal conversion, to realize the complex industrial system of accurate control and protection. In the design selection, only fully understand its working principle and application characteristics, in order to give full play to the potential of the limit switch to ensure the efficient and stable operation of the system.

Principle Analysis

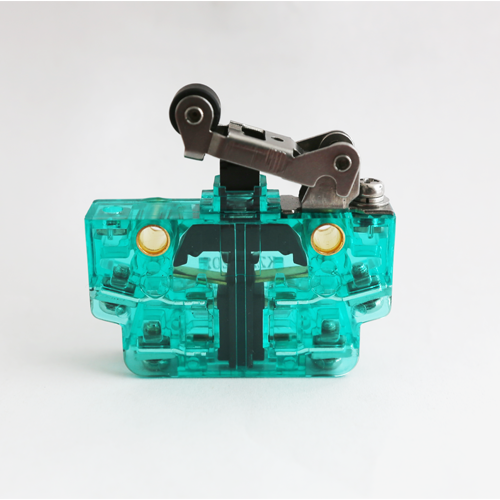

In terms of working principle, limit switches achieve their function based on the interaction between mechanical trigger parts and actuating parts. When the mechanical movement reaches the set limit position, the trigger part will actuate the contact of the switch, thus changing the on/off state of the circuit. This change can either close or break the circuit, depending on the configuration of the other electrical components used in combination with the limit switch.

Types

The types of limit switches are divided into two main categories: contact and non-contact. Contact limit switches detect the presence of an object through physical contact and are commonly used in industrial production lines for simple and direct position detection. Non-contact limit switches, on the other hand, utilize magnetic, photoelectric and other technologies to sense objects without direct contact, and are suitable for scenarios that require higher accuracy and response speed.

Application Cases

In practical applications, limit switches are widely used in many fields, such as construction, harbor, mining and so on. In cranes, transmission machinery and other equipment, limit switches are used for the control and limitation of spatial coordinates to ensure the safety of equipment operation and improve efficiency. In elevator control system, limit switches undertake the tasks of controlling the speed of opening and closing the car door, automatically opening and closing the door limit, as well as protecting the upper and lower limits of the car to ensure the safety of riding.

Design selection

In the face of different types of limit switches, the design selection needs to consider the application environment, mechanical strength of the equipment, environmental adaptability and other factors. For example, when applying in high-temperature environment, high-temperature-resistant limit switches, such as YNTH series, should be selected; and in the scenes with special requirements on protection level, products with high protection performance should be selected.

Overall, although the limit switch is small, the role should not be underestimated. It is through a simple mechanical and electrical signal conversion, to realize the complex industrial system of accurate control and protection. In the design selection, only fully understand its working principle and application characteristics, in order to give full play to the potential of the limit switch to ensure the efficient and stable operation of the system.