How to choose the right auxiliary switch for a spring mechanism?

Release time:2024-08-30

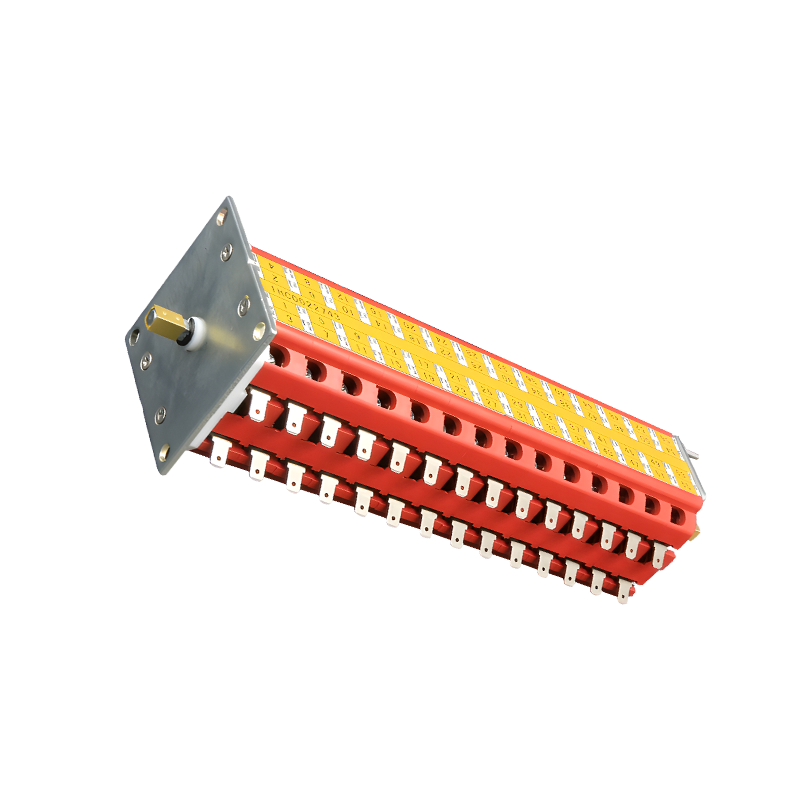

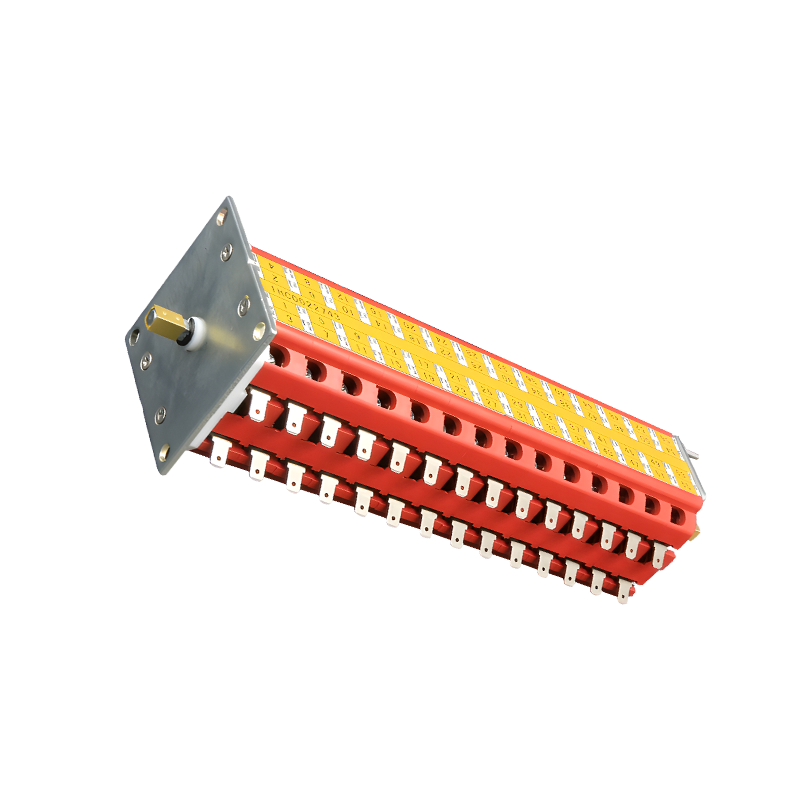

When designing or maintaining a spring mechanism, choosing the right auxiliary switch is critical to ensuring system reliability and efficiency. Auxiliary switches not only monitor the current state of the spring mechanism, but also shut off power when necessary to avoid damage, so it is important to understand how to select the right auxiliary switch for your spring mechanism.

First, consider the type of switch required. There are a variety of auxiliary switches on the market, including microswitches, magnetic switches and photoelectric switches. Each type of switch has its own specific usage scenarios and benefits. For example, microswitches are suitable for applications that require high precision and frequent operation, while magnetic switches are more suitable for applications in harsh environments.

Next, evaluate the operating voltage and current requirements. Different auxiliary switches are designed to withstand different voltage and current ranges. When selecting a switch, make sure its rated parameters meet the operating conditions of the spring mechanism to prevent damage or failure due to overloading.

Further, check the mechanical characteristics. The speed and force with which the spring mechanism is operated will have a direct impact on the selection of the auxiliary switch. High-speed operation may require a fast-responding switch, while vigorous operation will require a switch with adequate mechanical strength and durability.

In addition, environmental factors should not be overlooked in the selection process. If the spring mechanism is in an environment with high temperatures, high humidity, or corrosive substances, it is important to select an auxiliary switch that can withstand these conditions to ensure long-term stable operation.

Finally, consider the ease of installation and maintenance. Auxiliary switches that are easy to install and low maintenance can reduce downtime and lower maintenance costs. Some switches are designed with easy-to-access terminals and adjustable action points, making installation and adjustment quick and easy.

In summary, selecting the right auxiliary switch is critical to the stable operation of a spring mechanism. By considering the type of switch, electrical requirements, mechanical characteristics, environmental factors, and ease of installation and maintenance, you can ensure that you select the best auxiliary switch for your spring mechanism. Remember, the right auxiliary switch not only improves the reliability of the system, but also extends the life of the equipment, resulting in better performance and economy.

First, consider the type of switch required. There are a variety of auxiliary switches on the market, including microswitches, magnetic switches and photoelectric switches. Each type of switch has its own specific usage scenarios and benefits. For example, microswitches are suitable for applications that require high precision and frequent operation, while magnetic switches are more suitable for applications in harsh environments.

Next, evaluate the operating voltage and current requirements. Different auxiliary switches are designed to withstand different voltage and current ranges. When selecting a switch, make sure its rated parameters meet the operating conditions of the spring mechanism to prevent damage or failure due to overloading.

Further, check the mechanical characteristics. The speed and force with which the spring mechanism is operated will have a direct impact on the selection of the auxiliary switch. High-speed operation may require a fast-responding switch, while vigorous operation will require a switch with adequate mechanical strength and durability.

In addition, environmental factors should not be overlooked in the selection process. If the spring mechanism is in an environment with high temperatures, high humidity, or corrosive substances, it is important to select an auxiliary switch that can withstand these conditions to ensure long-term stable operation.

Finally, consider the ease of installation and maintenance. Auxiliary switches that are easy to install and low maintenance can reduce downtime and lower maintenance costs. Some switches are designed with easy-to-access terminals and adjustable action points, making installation and adjustment quick and easy.

In summary, selecting the right auxiliary switch is critical to the stable operation of a spring mechanism. By considering the type of switch, electrical requirements, mechanical characteristics, environmental factors, and ease of installation and maintenance, you can ensure that you select the best auxiliary switch for your spring mechanism. Remember, the right auxiliary switch not only improves the reliability of the system, but also extends the life of the equipment, resulting in better performance and economy.