Microswitches and Limit Switches: Key Differences Explained

Release time:2024-08-29

Micro switches and limit switches play an integral role in modern industrial automation and electronic equipment. Although both types of switches are used to control the opening and closing of circuits, they have significant differences in terms of working principle, application scenarios, and characteristics.

Difference in working principle:

Limit switches are mainly used to limit the movement of mechanical equipment limit position. It includes both contact and non-contact types. The contact type limit switch changes or cuts off the control circuit through the contact between the mechanical contact and the block to affect the mechanical movement. Non-contact limit switches, such as proximity switches, on the other hand, do not require direct contact and are activated by sensing the proximity of an object.

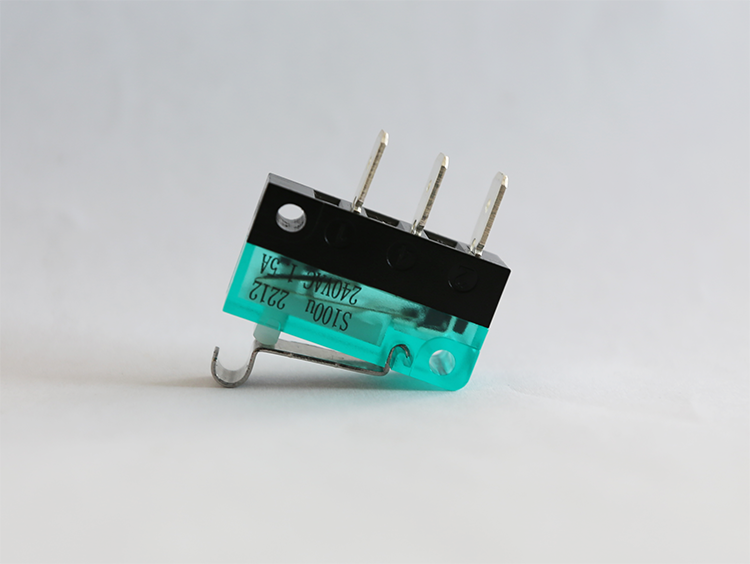

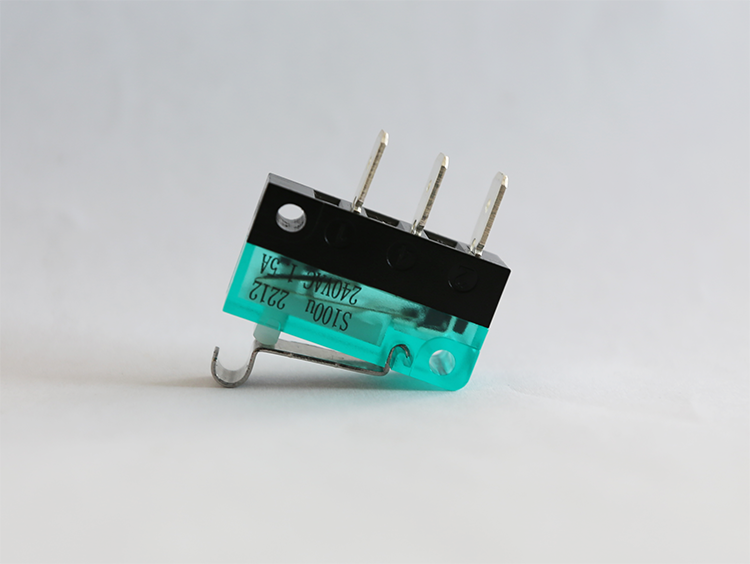

Micro switches, so named because of their tiny contact spacing, are quick-change switches that apply pressure to actuate. When an external force is applied to the actuating reed, it quickly turns on or off the moving and fixed contacts. Micro switches are widely used in equipment that requires frequent circuit switching because of their fast response and high reliability.

Differences in application scenarios:

Limit switches are commonly used for protection and positioning of mechanical equipment, such as preventing accidents from occurring when the mechanism exceeds its design range. Working limit switches are used to indicate whether a mechanism is in place or not, while limit switches are used to protect the mechanism from exceeding its limits.

Microswitches are used in a wider range of applications, including electronic equipment, test instruments, household appliances, and so on. Typical applications such as computer mice and automotive electronics rely on the high quality and durability of microswitches.

Comparison of characteristics:

Limit switches are characterized by their ability to withstand large mechanical forces and their adaptability to the environment, such as waterproof, shockproof and corrosion-resistant. Its existence ensures the safe operation of mechanical equipment.

Micro switches are characterized by fast reaction speed, small contact spacing, and small pressing force, which makes them outstanding in occasions that require fast and precise control. At the same time, microswitches also have a variety of models to adapt to different environments and functional requirements, such as waterproof, dustproof, explosion-proof and so on.

In summary, although both microswitches and limit switches are circuit control elements, they have different design principles, application ranges and performance characteristics. Understanding these differences is critical to selecting the right type of switch to maximize the operational efficiency and safety of your equipment. In industrial automation and electronic product design, proper switch selection will have a direct impact on product performance and reliability.

Difference in working principle:

Limit switches are mainly used to limit the movement of mechanical equipment limit position. It includes both contact and non-contact types. The contact type limit switch changes or cuts off the control circuit through the contact between the mechanical contact and the block to affect the mechanical movement. Non-contact limit switches, such as proximity switches, on the other hand, do not require direct contact and are activated by sensing the proximity of an object.

Micro switches, so named because of their tiny contact spacing, are quick-change switches that apply pressure to actuate. When an external force is applied to the actuating reed, it quickly turns on or off the moving and fixed contacts. Micro switches are widely used in equipment that requires frequent circuit switching because of their fast response and high reliability.

Differences in application scenarios:

Limit switches are commonly used for protection and positioning of mechanical equipment, such as preventing accidents from occurring when the mechanism exceeds its design range. Working limit switches are used to indicate whether a mechanism is in place or not, while limit switches are used to protect the mechanism from exceeding its limits.

Microswitches are used in a wider range of applications, including electronic equipment, test instruments, household appliances, and so on. Typical applications such as computer mice and automotive electronics rely on the high quality and durability of microswitches.

Comparison of characteristics:

Limit switches are characterized by their ability to withstand large mechanical forces and their adaptability to the environment, such as waterproof, shockproof and corrosion-resistant. Its existence ensures the safe operation of mechanical equipment.

Micro switches are characterized by fast reaction speed, small contact spacing, and small pressing force, which makes them outstanding in occasions that require fast and precise control. At the same time, microswitches also have a variety of models to adapt to different environments and functional requirements, such as waterproof, dustproof, explosion-proof and so on.

In summary, although both microswitches and limit switches are circuit control elements, they have different design principles, application ranges and performance characteristics. Understanding these differences is critical to selecting the right type of switch to maximize the operational efficiency and safety of your equipment. In industrial automation and electronic product design, proper switch selection will have a direct impact on product performance and reliability.