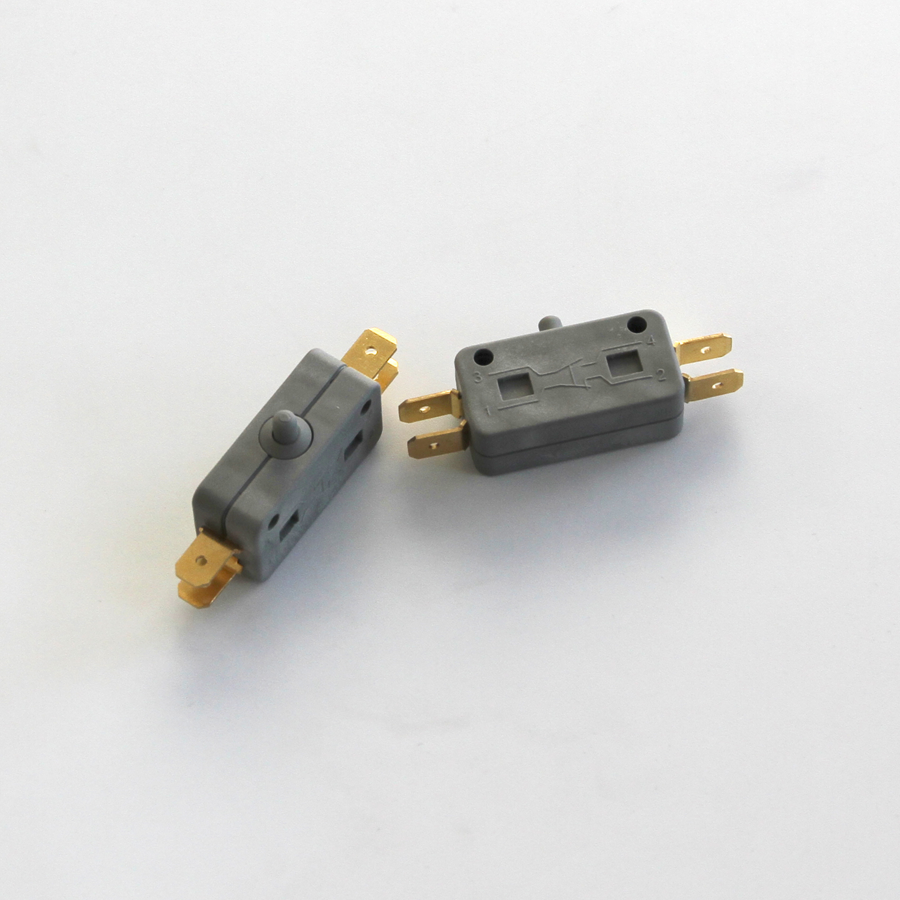

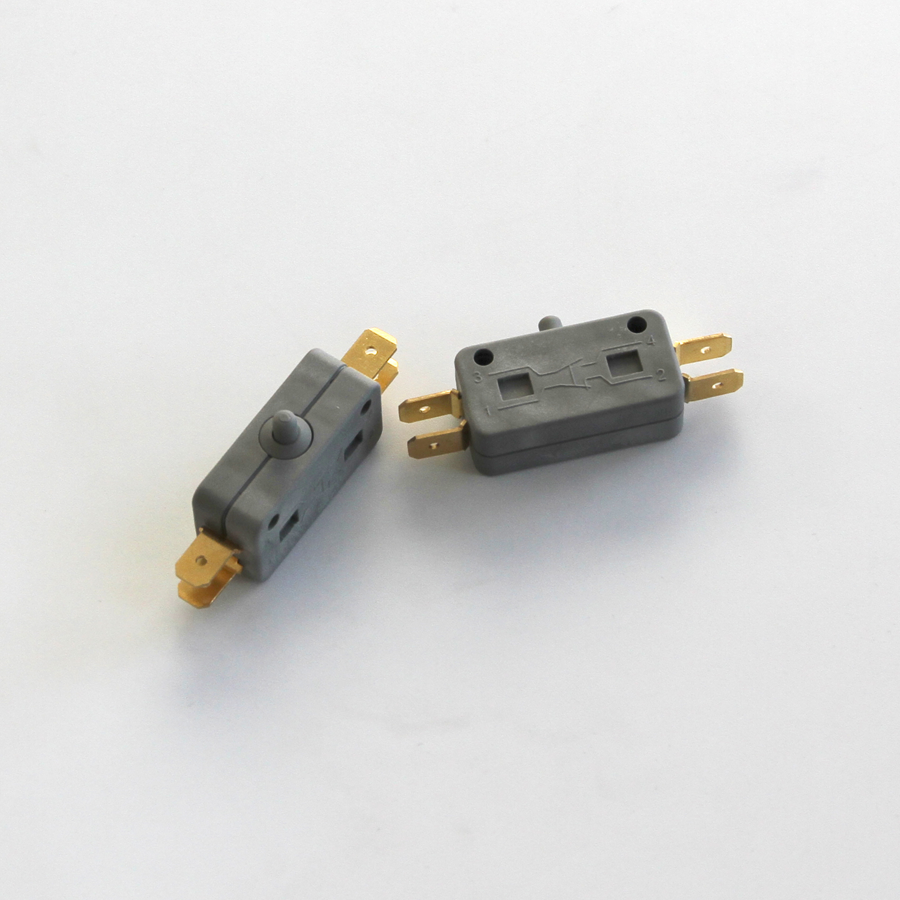

What is the difference between the contact materials of microswitches?

Release time:2024-08-28

Micro switches offer a wide range of options when it comes to the selection of electrical contact materials, mainly including gold, silver and their alloys as well as gold and silver plating. These different materials exhibit their own characteristics and advantages in terms of conductivity, hardness, corrosion resistance and cost. The differences between these contact materials will be explored in detail below:

1. Pure gold contacts:

Gold is extremely resistant to corrosion and does not oxidize easily, which ensures its stability and long-term reliability in harsh environments.

Pure gold contacts have excellent conductivity and provide stable electrical performance.

The soft texture of pure gold contacts allows them to fit better with the mating contacts during the contact process, ensuring a good electrical connection.

However, pure gold is softer and more expensive, so it may not be the most economical choice for applications that are subjected to higher currents or frequent operation.

2. sterling silver contacts:

Sterling silver has a low resistance, which makes it perform well in applications that require fast current transfer.

Silver contacts are often used where high conductivity and good solderability are required.

However, sterling silver contacts are susceptible to oxidation and vulcanization, which can lead to increased contact resistance, affecting the performance and life of the switch.

3. Silver alloy contacts:

In order to improve the defects of pure silver contacts, silver alloy contacts, such as silver cadmium, silver nickel or silver oxide, are usually used.

These alloys have greater mechanical strength and wear resistance than pure silver, while maintaining better electrical conductivity.

Silver alloy contacts also show better resistance to oxidation, thus extending the service life of the switch.

4. Gold and silver plated contacts:

Gold-silver plating is a thin layer of gold or silver over a base metal, combining the advantages of both to achieve a balance of cost and performance.

This contact material provides additional protection against corrosion while maintaining good electrical conductivity.

Gold and silver plated contacts are suitable for common applications where stability and longevity are important, but which do not have to withstand extreme environments.

In addition, when selecting contact materials for microswitches, in addition to considering the physical and chemical properties of the various materials mentioned above, the decision should also be based on the needs of the actual application. For example, for high-power or high-current applications, it may be necessary to select materials with higher resistance to arc erosion; while in precision instruments, priority may be given to materials with high electrical conductivity and stability.

In conclusion, the choice of contact materials for microswitches involves the comparison of the characteristics of a variety of materials and the matching of applications. The correct choice of materials not only enhances the overall performance of the switching device, but also effectively controls the cost and extends the product life.

1. Pure gold contacts:

Gold is extremely resistant to corrosion and does not oxidize easily, which ensures its stability and long-term reliability in harsh environments.

Pure gold contacts have excellent conductivity and provide stable electrical performance.

The soft texture of pure gold contacts allows them to fit better with the mating contacts during the contact process, ensuring a good electrical connection.

However, pure gold is softer and more expensive, so it may not be the most economical choice for applications that are subjected to higher currents or frequent operation.

2. sterling silver contacts:

Sterling silver has a low resistance, which makes it perform well in applications that require fast current transfer.

Silver contacts are often used where high conductivity and good solderability are required.

However, sterling silver contacts are susceptible to oxidation and vulcanization, which can lead to increased contact resistance, affecting the performance and life of the switch.

3. Silver alloy contacts:

In order to improve the defects of pure silver contacts, silver alloy contacts, such as silver cadmium, silver nickel or silver oxide, are usually used.

These alloys have greater mechanical strength and wear resistance than pure silver, while maintaining better electrical conductivity.

Silver alloy contacts also show better resistance to oxidation, thus extending the service life of the switch.

4. Gold and silver plated contacts:

Gold-silver plating is a thin layer of gold or silver over a base metal, combining the advantages of both to achieve a balance of cost and performance.

This contact material provides additional protection against corrosion while maintaining good electrical conductivity.

Gold and silver plated contacts are suitable for common applications where stability and longevity are important, but which do not have to withstand extreme environments.

In addition, when selecting contact materials for microswitches, in addition to considering the physical and chemical properties of the various materials mentioned above, the decision should also be based on the needs of the actual application. For example, for high-power or high-current applications, it may be necessary to select materials with higher resistance to arc erosion; while in precision instruments, priority may be given to materials with high electrical conductivity and stability.

In conclusion, the choice of contact materials for microswitches involves the comparison of the characteristics of a variety of materials and the matching of applications. The correct choice of materials not only enhances the overall performance of the switching device, but also effectively controls the cost and extends the product life.