What are the contact materials for micro switches?

Release time:2024-08-27

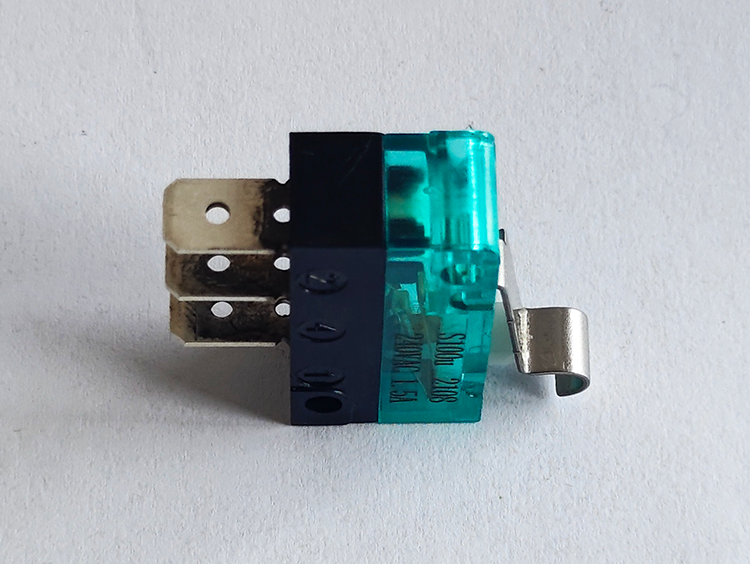

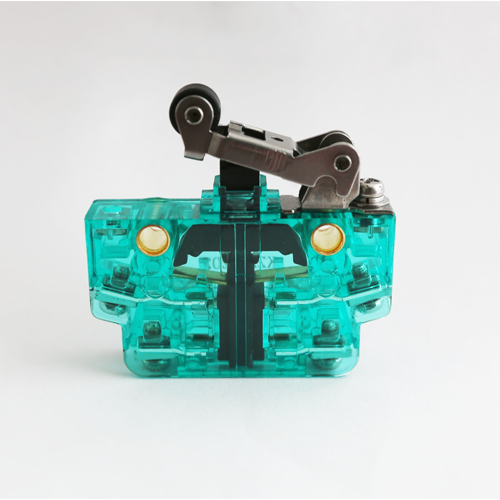

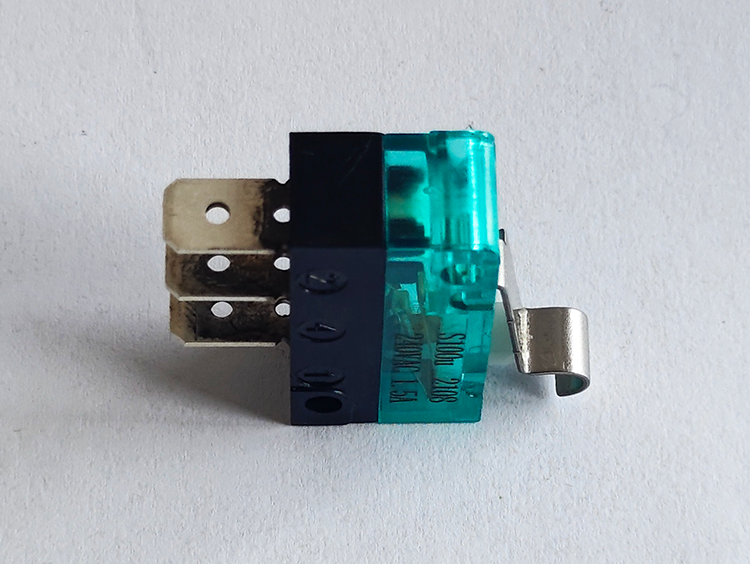

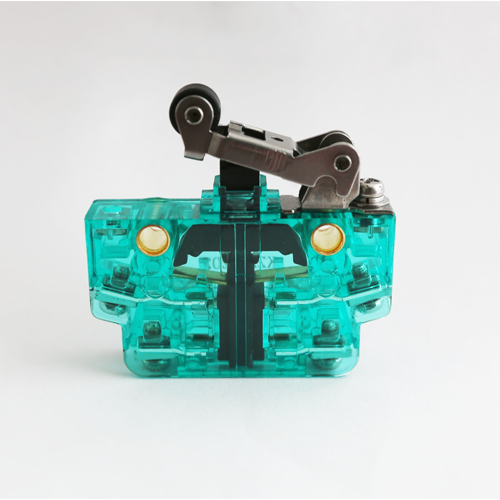

Micro switches, a type of switch with tiny contact intervals and a tacho mechanism, play a vital role in many electronic devices and machines. The contact material, in particular, has a profound effect on the performance of the switch. The following is a detailed discussion of micro switches contact materials and their characteristics.

Gold and its alloys

Pure gold contacts: Pure gold is the preferred material for making electrical contacts due to its excellent conductivity and non-oxidizing properties. However, pure gold is soft and tends to wear out after many operations, and is prone to arcing at higher currents, which accelerates contact wear. Pure gold is mainly used for signal grade or low load microswitches.

Gold-Silver Alloy Contacts: To improve the hardness and durability of pure gold, alloys are often formed with other metals such as silver. Silver adds hardness while gold protects against oxidation. This alloy improves the wear and arc resistance of the contacts while maintaining good electrical conductivity. They are suitable for applications requiring frequent operation and heavy loads.

Silver and its alloys

Sterling Silver Contacts: Sterling silver contacts have good conductivity and ductility, but are more susceptible to oxidation than gold. Sterling silver contacts excel in light load and medium current applications. However, because they are softer, they are not suitable for high load environments.

Silver Alloy Contacts: Common silver alloys include silver-nickel and silver-cadmium. These alloys are designed to increase the hardness and solder resistance of pure silver through the addition of other metals, allowing it to withstand higher currents and operating frequencies. Silver alloy contacts offer a better balance between durability and cost.

Other Alloys and Materials

Copper alloy contacts: such as brass and beryllium bronze, these materials are more electrically conductive but harder than gold and silver alloys, making them more suitable as contact materials for microswitches with large loads or high operating forces. Copper alloys are usually less costly, but may be less resistant to corrosion and oxidation than precious metals.

Platinum Group Metal Contacts: Including platinum and palladium, these materials are primarily used in specialized environments, such as high temperatures or corrosive gases, where their ability to combat extreme conditions is significantly better than conventional metallic materials.

Overall, there are a wide variety of contact material options for microswitches, each with its own unique benefits and application scenarios. The correct choice of contact material is critical to ensuring the operational performance and longevity of the switch.

Gold and its alloys

Pure gold contacts: Pure gold is the preferred material for making electrical contacts due to its excellent conductivity and non-oxidizing properties. However, pure gold is soft and tends to wear out after many operations, and is prone to arcing at higher currents, which accelerates contact wear. Pure gold is mainly used for signal grade or low load microswitches.

Gold-Silver Alloy Contacts: To improve the hardness and durability of pure gold, alloys are often formed with other metals such as silver. Silver adds hardness while gold protects against oxidation. This alloy improves the wear and arc resistance of the contacts while maintaining good electrical conductivity. They are suitable for applications requiring frequent operation and heavy loads.

Silver and its alloys

Sterling Silver Contacts: Sterling silver contacts have good conductivity and ductility, but are more susceptible to oxidation than gold. Sterling silver contacts excel in light load and medium current applications. However, because they are softer, they are not suitable for high load environments.

Silver Alloy Contacts: Common silver alloys include silver-nickel and silver-cadmium. These alloys are designed to increase the hardness and solder resistance of pure silver through the addition of other metals, allowing it to withstand higher currents and operating frequencies. Silver alloy contacts offer a better balance between durability and cost.

Other Alloys and Materials

Copper alloy contacts: such as brass and beryllium bronze, these materials are more electrically conductive but harder than gold and silver alloys, making them more suitable as contact materials for microswitches with large loads or high operating forces. Copper alloys are usually less costly, but may be less resistant to corrosion and oxidation than precious metals.

Platinum Group Metal Contacts: Including platinum and palladium, these materials are primarily used in specialized environments, such as high temperatures or corrosive gases, where their ability to combat extreme conditions is significantly better than conventional metallic materials.

Overall, there are a wide variety of contact material options for microswitches, each with its own unique benefits and application scenarios. The correct choice of contact material is critical to ensuring the operational performance and longevity of the switch.