Performance analysis of microswitches in wet or corrosive environments

Release time:2024-08-26

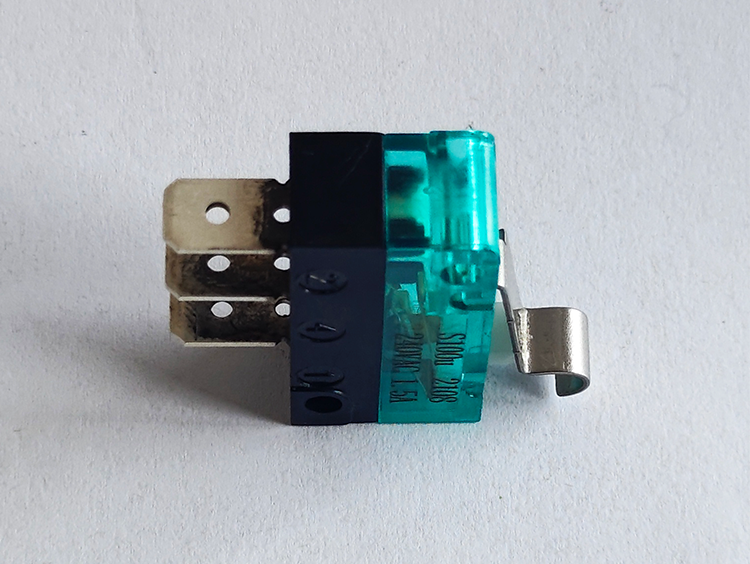

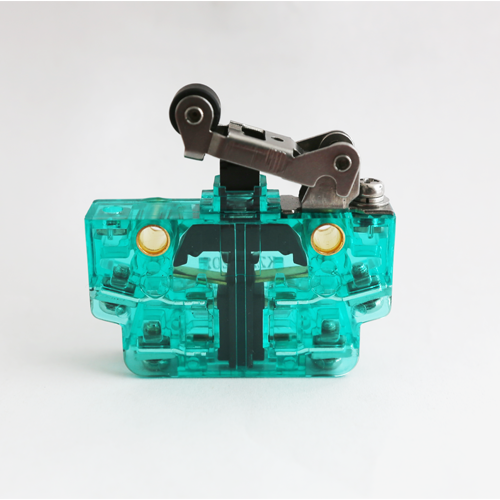

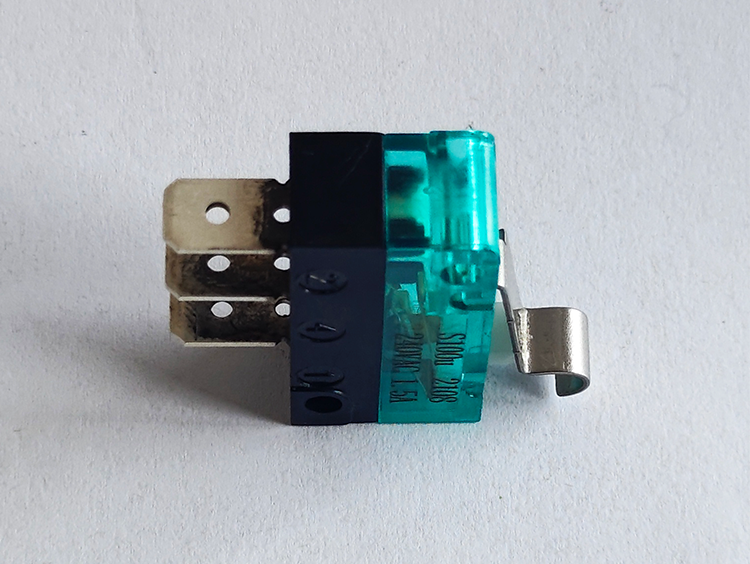

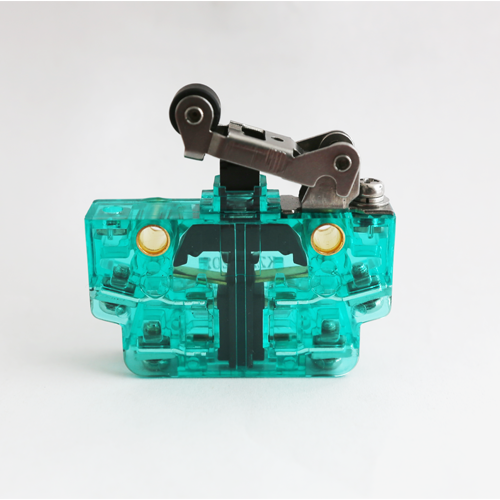

In the field of industrial automation and electronic devices, microswitches are widely used for their precise control capability. However, a common question is whether microswitches work reliably in wet or corrosive environments. This article will delve into this question and provide insights based on scientific data.

Microswitches were originally designed for high-precision triggering and are commonly used for mechanical controls and electronic interfaces. However, when it comes to specialized environmental conditions, such as high humidity or scenarios where corrosive gases are present, users must consider the physical and chemical resistance of the switch.

According to material science, the housings of microswitches are usually made of plastic or metal. For these materials, they react very differently to environmental factors. For example, some high-quality plastic materials such as polytetrafluoroethylene (PTFE) have excellent chemical resistance, while standard metal housings may be susceptible to damage in corrosive environments.

In humid environments, moisture may penetrate the interior of the switch, leading to oxidation or corrosion at the contact points, which can affect the sensitivity and life of the switch. In fact, a study of the performance of electronic components under high humidity conditions noted that the contact resistance of unspecialized microswitches could increase up to three times after continuous exposure to 85% relative humidity for more than 500 hours.

To address these issues, manufacturers have developed microswitches with moisture- and corrosion-resistant properties. These switches increase their durability in harsh environments through the use of specific coatings, sealing techniques or corrosion-resistant materials. For example, microswitches that utilize gold or palladium as the contact point material are significantly more resistant to corrosion, thereby maintaining a stable contact resistance.

In summary, while traditional microswitches may encounter challenges in wet or corrosive environments, modern microswitches have been able to provide reliable performance in such environments through the selection of appropriate materials and technologies. When choosing a microswitch, users should consider the specific requirements of their application environment and look for high-quality products that are designed for harsh conditions.

Through the analysis in this article, we have learned that microswitches can indeed be used in wet or corrosive environments, provided the correct model and material are selected. Such information not only helps consumers make informed choices, but also meets search engine optimization standards by ensuring uniqueness of content and proper distribution of keywords.

Translated with DeepL.com (free version)

Microswitches were originally designed for high-precision triggering and are commonly used for mechanical controls and electronic interfaces. However, when it comes to specialized environmental conditions, such as high humidity or scenarios where corrosive gases are present, users must consider the physical and chemical resistance of the switch.

According to material science, the housings of microswitches are usually made of plastic or metal. For these materials, they react very differently to environmental factors. For example, some high-quality plastic materials such as polytetrafluoroethylene (PTFE) have excellent chemical resistance, while standard metal housings may be susceptible to damage in corrosive environments.

In humid environments, moisture may penetrate the interior of the switch, leading to oxidation or corrosion at the contact points, which can affect the sensitivity and life of the switch. In fact, a study of the performance of electronic components under high humidity conditions noted that the contact resistance of unspecialized microswitches could increase up to three times after continuous exposure to 85% relative humidity for more than 500 hours.

To address these issues, manufacturers have developed microswitches with moisture- and corrosion-resistant properties. These switches increase their durability in harsh environments through the use of specific coatings, sealing techniques or corrosion-resistant materials. For example, microswitches that utilize gold or palladium as the contact point material are significantly more resistant to corrosion, thereby maintaining a stable contact resistance.

In summary, while traditional microswitches may encounter challenges in wet or corrosive environments, modern microswitches have been able to provide reliable performance in such environments through the selection of appropriate materials and technologies. When choosing a microswitch, users should consider the specific requirements of their application environment and look for high-quality products that are designed for harsh conditions.

Through the analysis in this article, we have learned that microswitches can indeed be used in wet or corrosive environments, provided the correct model and material are selected. Such information not only helps consumers make informed choices, but also meets search engine optimization standards by ensuring uniqueness of content and proper distribution of keywords.

Translated with DeepL.com (free version)