Stability analysis of microswitch performance at extreme temperatures

Release time:2024-08-22

Microswitch, a common mechanical switching device, is widely used in various electronic devices and control systems. When choosing microswitches, users not only pay attention to their basic electrical performance, but also often ask about their stability in high or low temperature environments. This article will explore the performance of microswitches under extreme temperature conditions based on the latest scientific research data.

I. Basic structure and working principle of microswitch

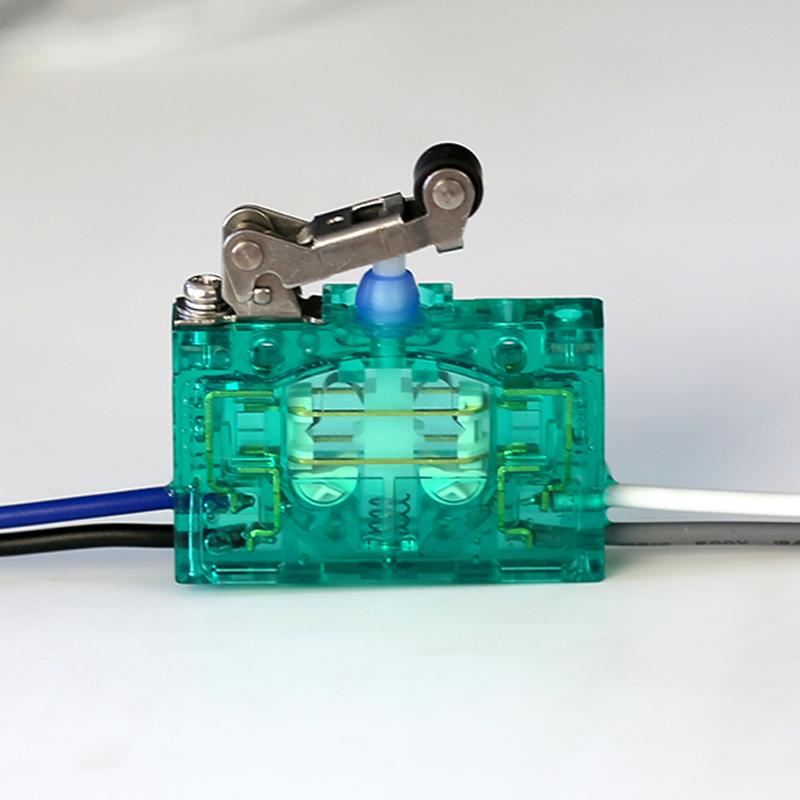

Microswitches are mainly composed of contacts, springs, drive rods and other components. When the external force is applied to the driving rod, the spring closes or breaks the contact, thus realizing the control of the circuit. Understanding its structure helps us to further analyze its performance in special environments.

Influence of high temperature environment on the performance of microswitches

According to industry standards, microswitches are usually required to work stably in the temperature range of -25°C to 85°C. However, in practice, they may encounter high temperatures. However, practical applications may encounter temperature conditions beyond this range. Studies have shown that at high temperatures, the plastic parts of microswitches may suffer from poor contact due to thermal expansion, while the metal parts may suffer from mechanical properties due to thermal stress.

Effect of low temperature on the performance of microswitches

In contrast to high temperatures, low temperatures may cause the lubricating oil inside the microswitch to solidify, increasing the coefficient of friction and thus affecting its response speed and life. Also, shrinkage of materials may cause contact instability.

IV. Improvement Measures Supported by Scientific Data

To improve the stability of microswitches at extreme temperatures, manufacturers often use high-temperature-resistant materials and design optimizations. Examples include the use of special high-temperature plastics and metal materials, as well as the addition of internal lubricants to reduce friction problems at low temperatures.

In summary, the stability of microswitches in use in high or low temperature environments is affected by a variety of factors. Despite the challenges, their performance in extreme temperature conditions can be significantly improved through scientific design and material selection. Users should consider the temperature range of their operating environment when selecting microswitches and consult a specialized manufacturer for the most appropriate product.

The stability of microswitches in high or low temperature environments is a complex technical problem that requires the joint efforts of manufacturers, researchers and users to solve. Through continuous technological innovation and scientific research, we expect to realize more stable and reliable microswitch solutions in the future.