How reliable are auxiliary switches?

Release time:2024-08-21

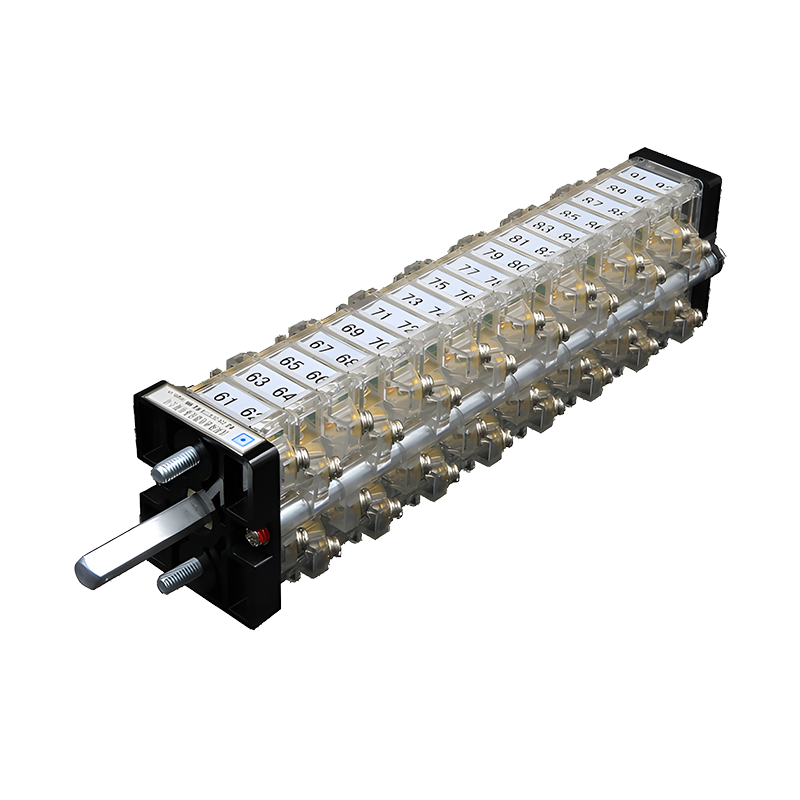

Auxiliary switches play an integral role in power systems and industrial automation. The main function of these devices is to monitor and control the operating status of electrical equipment, to transmit signals and to provide feedback through the opening and closing of their contacts. Therefore, it is important to explore “how reliable are auxiliary switches”, which is the focus of this paper.

Auxiliary switches are often used in conjunction with main switches or circuit breakers to provide signal feedback and additional control and protection functions. The core of this device is its ability to recognize the operating conditions of the connected equipment through the opening and closing of contacts for automated control and fault detection.

Regarding the reliability of auxiliary switches, the following dimensions can be analyzed in detail:

1. structure and operating mode:

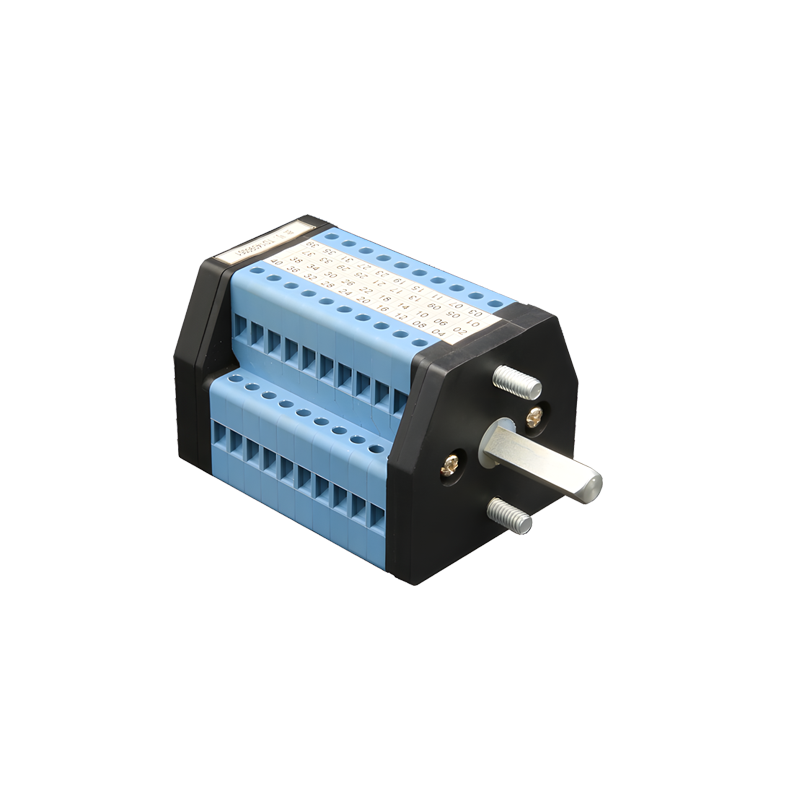

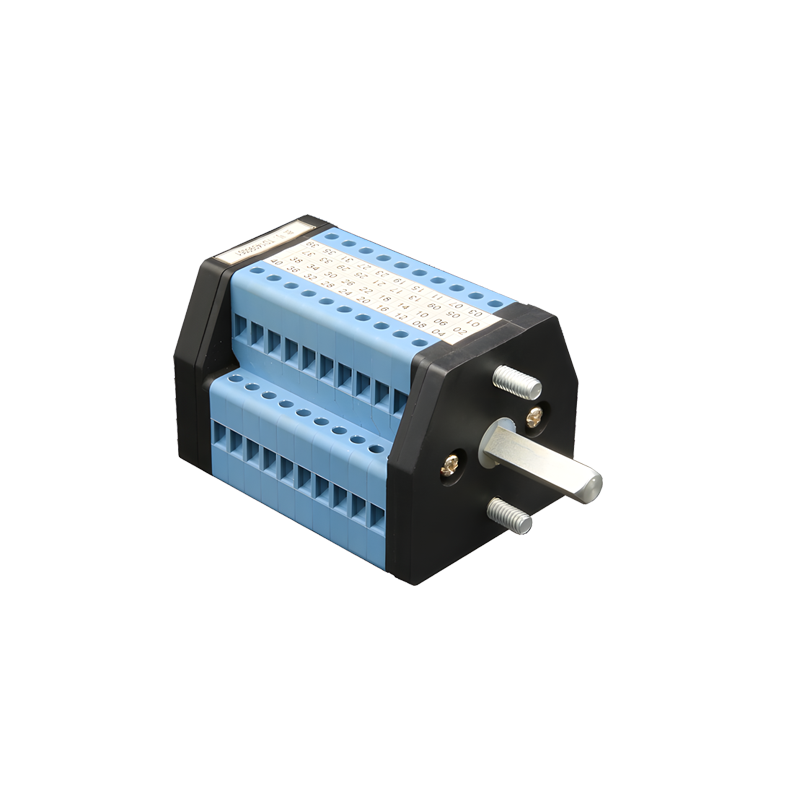

Auxiliary switches can be categorized into mechanical, electromagnetic, photoelectric and electronic according to their structure and working principle. Each type is designed for a specific application scenario to ensure maximum effectiveness and reliability in the corresponding environment.

Mechanical auxiliary switches open and close contacts through physical operation and are suitable for applications requiring manual intervention. On the other hand, electromagnetic, photoelectric and electronic types utilize electromagnetic force, optical signals and electronics respectively to achieve control, which is suitable for automation and high-precision control needs.

2. Key performance parameters:

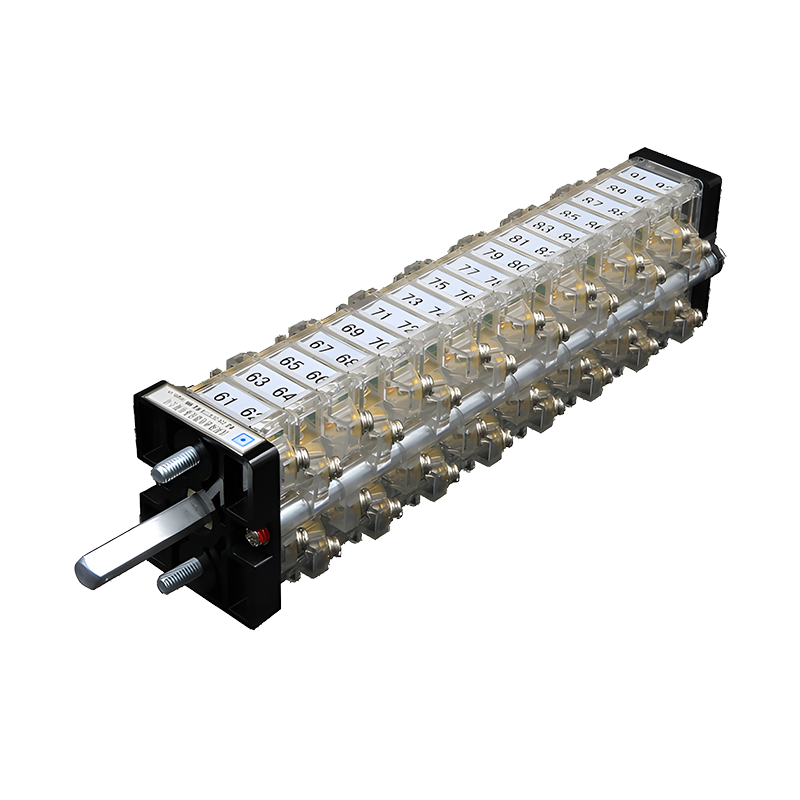

The reliability of an auxiliary switch is affected by a variety of factors, such as the choice of materials for the contacts, the durability of the contacts, and the frequency of operation that the switch can withstand. High-quality materials and precise manufacturing processes are key to ensuring long-term reliable operation.

Auxiliary switches are often designed with the ability to maintain stability under high frequency operation in mind, which is extremely important in modern industrial environments that require frequent monitoring and control.

3. Environmental adaptability:

Depending on the operating environment, auxiliary switches are designed with different levels of protection and temperature tolerance ranges to ensure proper operation in harsh environments.

For chemically aggressive environments, specific models of auxiliary switches are made of corrosion-resistant materials to enhance durability and reliability.

4. Common applications and real-world performance:

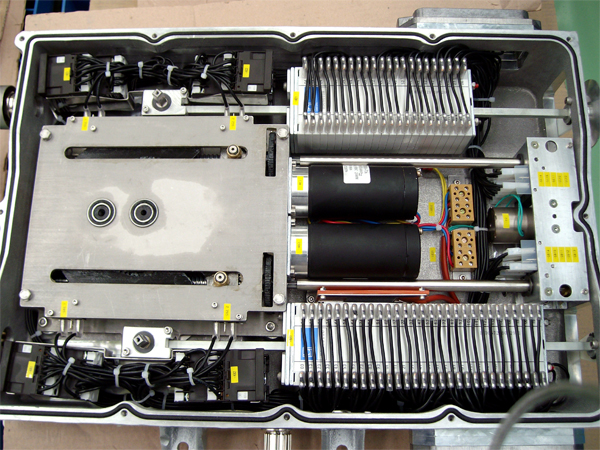

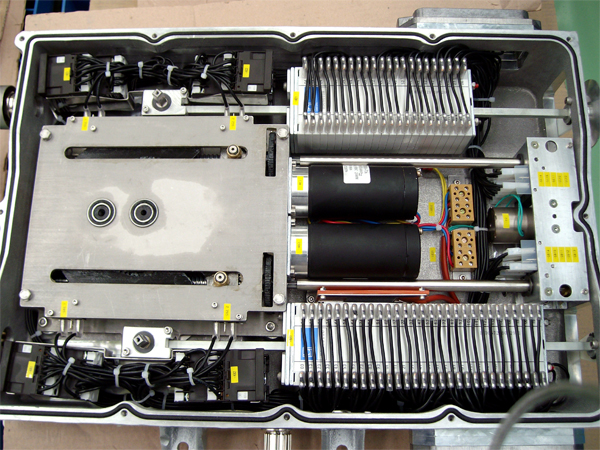

In industrial automation, energy management, home intelligence and other fields, auxiliary switches are widely used to monitor and control the status of circuits, and their precise performance directly affects the stable operation of the system.

For example, in automation control systems, electromagnetic auxiliary switches realize remote control through the cooperation of electromagnetic coils and mechanical structures, which improves the safety of operation and the response speed of the system.

5. Maintenance and troubleshooting:

Although auxiliary switches are designed to be highly reliable, routine inspection and maintenance are necessary, including periodic contact cleaning and connection checks to prevent poor contact or signal interruption.

Prompt troubleshooting and component replacement when abnormal auxiliary switch function is detected can effectively minimize system downtime and ensure continuous production.

The reliability of auxiliary switches is also reflected in their contribution to system safety. A good auxiliary switch not only provides precise feedback on the operating status, but also prevents potential electrical accidents through linkage control, such as instantaneous disconnection in the event of an overload or short circuit.

To summarize, the reliability of an auxiliary switch is determined by a combination of factors such as its structural design, material selection, environmental adaptability and ease of maintenance. In practical application, choosing the right auxiliary switch and doing routine maintenance is the key to ensure its continuous and stable operation. With the continuous progress of technology, it is expected that auxiliary switches will be more intelligent and efficient in the future, and better serve all kinds of power and automation systems.

Auxiliary switches are often used in conjunction with main switches or circuit breakers to provide signal feedback and additional control and protection functions. The core of this device is its ability to recognize the operating conditions of the connected equipment through the opening and closing of contacts for automated control and fault detection.

Regarding the reliability of auxiliary switches, the following dimensions can be analyzed in detail:

1. structure and operating mode:

Auxiliary switches can be categorized into mechanical, electromagnetic, photoelectric and electronic according to their structure and working principle. Each type is designed for a specific application scenario to ensure maximum effectiveness and reliability in the corresponding environment.

Mechanical auxiliary switches open and close contacts through physical operation and are suitable for applications requiring manual intervention. On the other hand, electromagnetic, photoelectric and electronic types utilize electromagnetic force, optical signals and electronics respectively to achieve control, which is suitable for automation and high-precision control needs.

2. Key performance parameters:

The reliability of an auxiliary switch is affected by a variety of factors, such as the choice of materials for the contacts, the durability of the contacts, and the frequency of operation that the switch can withstand. High-quality materials and precise manufacturing processes are key to ensuring long-term reliable operation.

Auxiliary switches are often designed with the ability to maintain stability under high frequency operation in mind, which is extremely important in modern industrial environments that require frequent monitoring and control.

3. Environmental adaptability:

Depending on the operating environment, auxiliary switches are designed with different levels of protection and temperature tolerance ranges to ensure proper operation in harsh environments.

For chemically aggressive environments, specific models of auxiliary switches are made of corrosion-resistant materials to enhance durability and reliability.

4. Common applications and real-world performance:

In industrial automation, energy management, home intelligence and other fields, auxiliary switches are widely used to monitor and control the status of circuits, and their precise performance directly affects the stable operation of the system.

For example, in automation control systems, electromagnetic auxiliary switches realize remote control through the cooperation of electromagnetic coils and mechanical structures, which improves the safety of operation and the response speed of the system.

5. Maintenance and troubleshooting:

Although auxiliary switches are designed to be highly reliable, routine inspection and maintenance are necessary, including periodic contact cleaning and connection checks to prevent poor contact or signal interruption.

Prompt troubleshooting and component replacement when abnormal auxiliary switch function is detected can effectively minimize system downtime and ensure continuous production.

The reliability of auxiliary switches is also reflected in their contribution to system safety. A good auxiliary switch not only provides precise feedback on the operating status, but also prevents potential electrical accidents through linkage control, such as instantaneous disconnection in the event of an overload or short circuit.

To summarize, the reliability of an auxiliary switch is determined by a combination of factors such as its structural design, material selection, environmental adaptability and ease of maintenance. In practical application, choosing the right auxiliary switch and doing routine maintenance is the key to ensure its continuous and stable operation. With the continuous progress of technology, it is expected that auxiliary switches will be more intelligent and efficient in the future, and better serve all kinds of power and automation systems.