What connections do I need to be aware of with an auxiliary switch?

Release time:2024-08-19

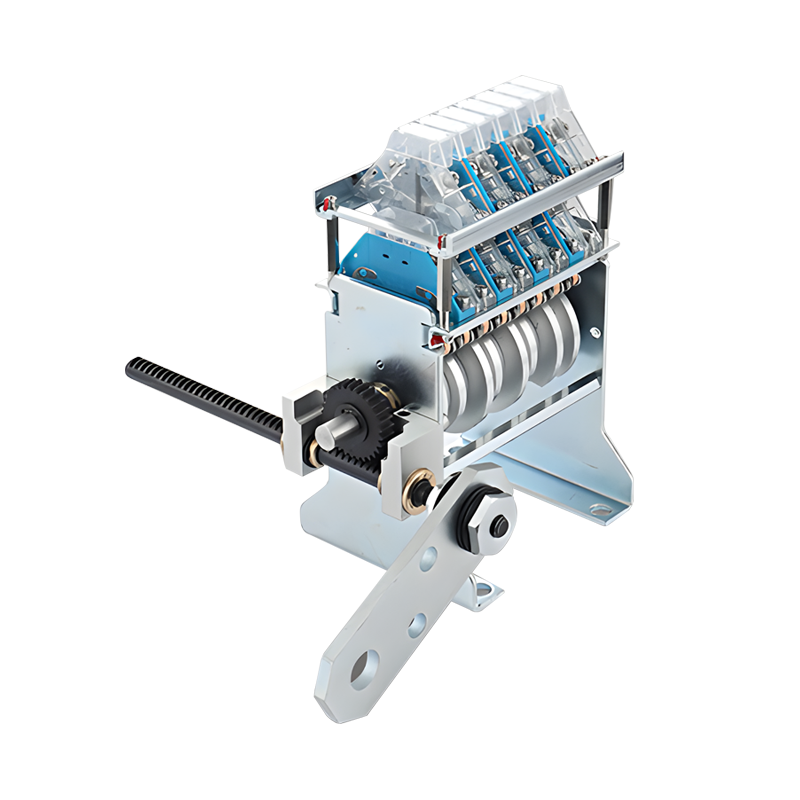

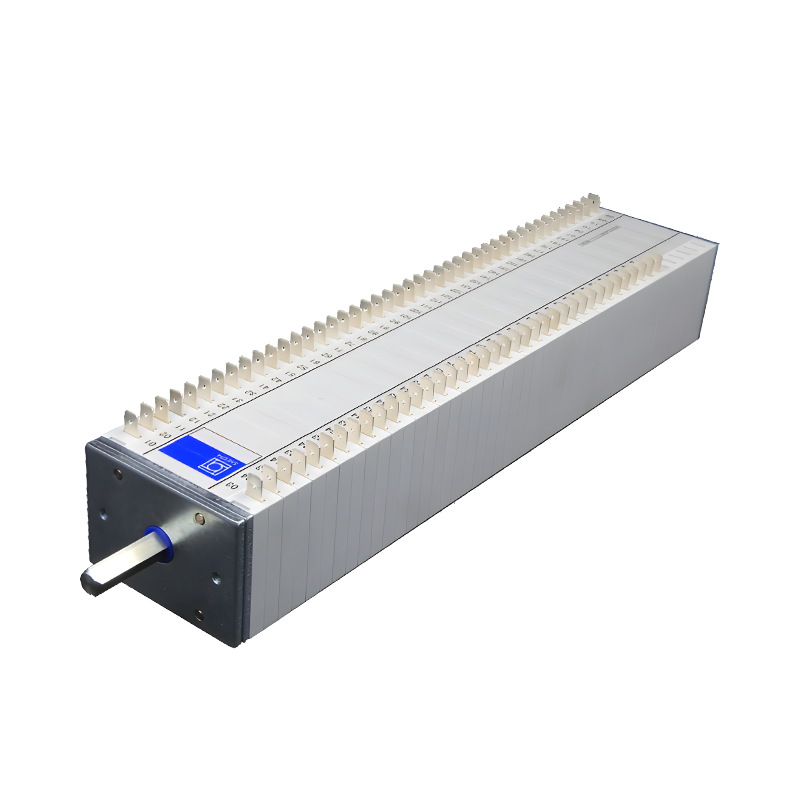

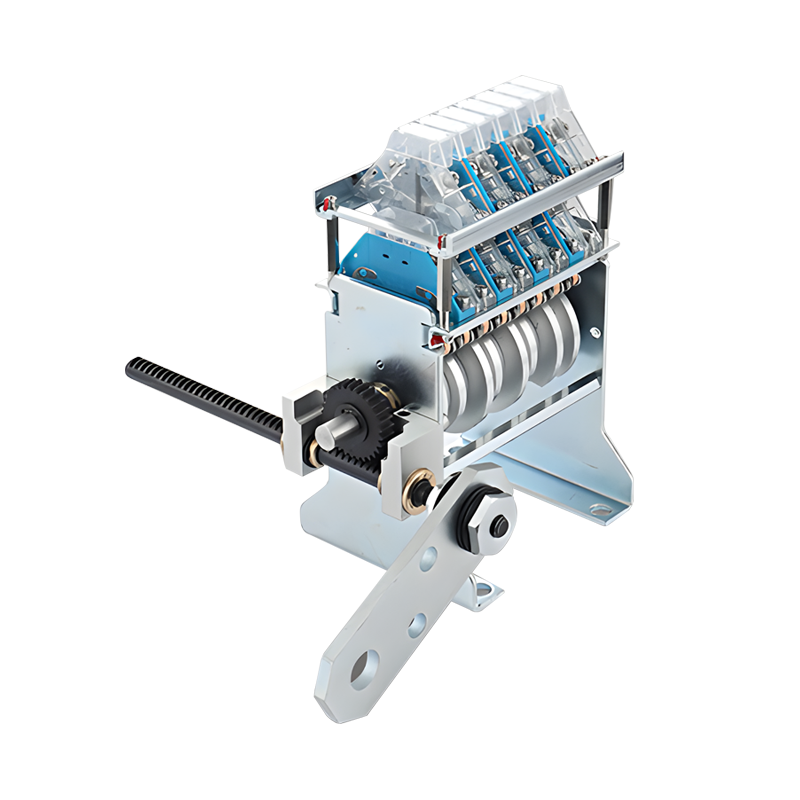

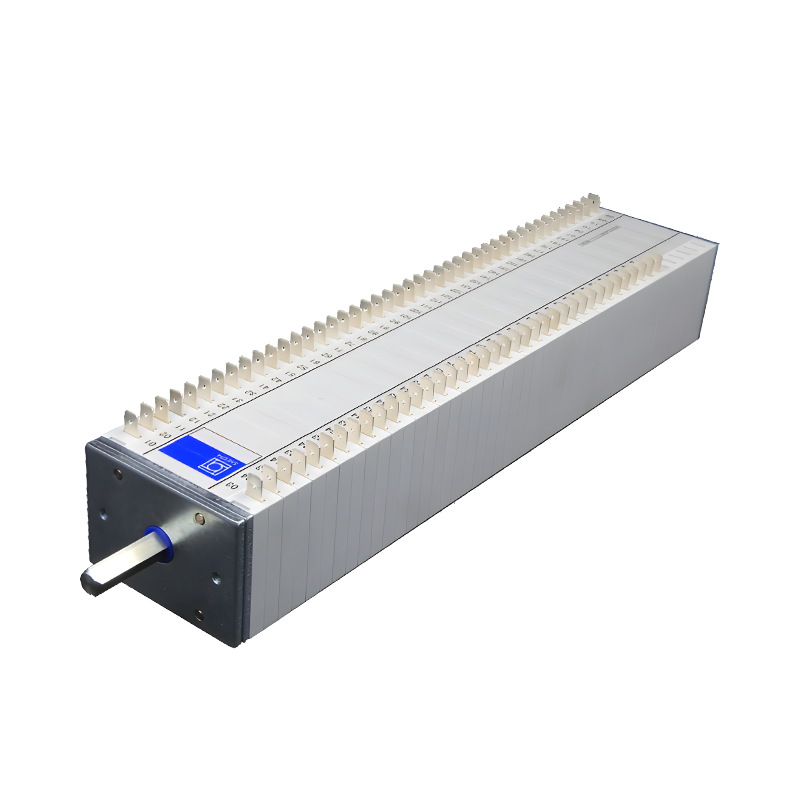

An auxiliary switch is an important power control device in a power system, which is usually used in conjunction with main power devices such as main switches or circuit breakers to provide additional signal feedback, control and protection functions. However, in practice, the connection of auxiliary switches is often overlooked, leading to system failures or safety hazards. Therefore, this paper will discuss in detail what problems auxiliary switches need to pay attention to in the connection process to ensure the stable operation of the power system.

First of all, we need to understand the basic function and principle of the auxiliary switch. The auxiliary switch transmits the operation signals and status information of the power equipment through the opening and closing states of the contacts. When the power equipment is in normal operation, the contact of the auxiliary switch will remain closed, transmitting a stable signal to the external system; and when the equipment fails or needs maintenance, the contact of the auxiliary switch will open, sending the corresponding signal in response.

Next, we will focus on the issues that need to be taken into account during the connection process of the auxiliary switch:

1. Connection stability: The connection of the auxiliary switch must be stable and reliable to avoid interruptions or errors in signal transmission due to poor contact. The connection point should be shockproof and anti-loosening design to minimize the impact on the connection stability due to external environmental changes (e.g. temperature changes, vibration, etc.).

2. Cable selection and wiring specification: Selection of suitable cables and wiring methods is essential to ensure the normal operation of the auxiliary switch. The cable should have good conductivity and sufficient cross-sectional area to minimize voltage drop and energy loss. The wiring should follow the relevant electrician's specifications to ensure that the wiring is firm and has good contact, and that the necessary protective measures are taken, such as the use of terminal blocks and junction boxes.

3. Preventing electrical noise interference: During the connection of the auxiliary switch, attention should be paid to preventing the interference of electrical noise. The influence of external noise on signal transmission can be minimized by reasonable wiring, use of shielded cables, installation of filters and so on.

4. Consideration of delay characteristic: Some auxiliary switches have the characteristic of delayed action, which means that the action of the switches will occur some time after receiving the command. This characteristic should be fully considered when designing the connection scheme to ensure the correctness of the control logic and the safety of the system.

5. Application of double contact characteristic: For auxiliary switches with double contact characteristic, it is possible to simplify the wiring and realize the control of two circuits at the same time. When connecting, make sure that the actions of the two contacts are synchronized to avoid control errors caused by inconsistent actions.

6. Connection of special contacts: For contacts with special action behavior, such as normally open contacts that open immediately after closing, special attention should be paid to their connection. These contacts are usually used in special control logic, the connection should ensure that its action characteristics to meet the system's control requirements.

7. Influence of environmental factors: The environment in which the auxiliary switch is used has an important influence on its connection performance. In harsh environments such as high temperature, high humidity, corrosive gases, etc., special protective measures should be taken, such as the use of high temperature, humidity and corrosion-resistant materials and coatings, as well as increased sealing measures.

8. Regular inspection and maintenance: During the use of auxiliary switches, their connection status should be checked regularly to detect and deal with potential problems in time. For the connection parts that are worn and aged, they should be replaced in time to ensure the long-term stable operation of the system.

In summary, the problems that need to be paid attention to in the connection process of auxiliary switches include connection stability, cable selection and wiring specifications, prevention of electrical noise interference, consideration of delay characteristics, application of double contact characteristics, connection of special contacts, the influence of environmental factors, and regular inspection and maintenance. By paying full attention to these issues and dealing with them properly, it can ensure that the auxiliary switch plays its due role in the power system and improve the reliability and safety of the system.

First of all, we need to understand the basic function and principle of the auxiliary switch. The auxiliary switch transmits the operation signals and status information of the power equipment through the opening and closing states of the contacts. When the power equipment is in normal operation, the contact of the auxiliary switch will remain closed, transmitting a stable signal to the external system; and when the equipment fails or needs maintenance, the contact of the auxiliary switch will open, sending the corresponding signal in response.

Next, we will focus on the issues that need to be taken into account during the connection process of the auxiliary switch:

1. Connection stability: The connection of the auxiliary switch must be stable and reliable to avoid interruptions or errors in signal transmission due to poor contact. The connection point should be shockproof and anti-loosening design to minimize the impact on the connection stability due to external environmental changes (e.g. temperature changes, vibration, etc.).

2. Cable selection and wiring specification: Selection of suitable cables and wiring methods is essential to ensure the normal operation of the auxiliary switch. The cable should have good conductivity and sufficient cross-sectional area to minimize voltage drop and energy loss. The wiring should follow the relevant electrician's specifications to ensure that the wiring is firm and has good contact, and that the necessary protective measures are taken, such as the use of terminal blocks and junction boxes.

3. Preventing electrical noise interference: During the connection of the auxiliary switch, attention should be paid to preventing the interference of electrical noise. The influence of external noise on signal transmission can be minimized by reasonable wiring, use of shielded cables, installation of filters and so on.

4. Consideration of delay characteristic: Some auxiliary switches have the characteristic of delayed action, which means that the action of the switches will occur some time after receiving the command. This characteristic should be fully considered when designing the connection scheme to ensure the correctness of the control logic and the safety of the system.

5. Application of double contact characteristic: For auxiliary switches with double contact characteristic, it is possible to simplify the wiring and realize the control of two circuits at the same time. When connecting, make sure that the actions of the two contacts are synchronized to avoid control errors caused by inconsistent actions.

6. Connection of special contacts: For contacts with special action behavior, such as normally open contacts that open immediately after closing, special attention should be paid to their connection. These contacts are usually used in special control logic, the connection should ensure that its action characteristics to meet the system's control requirements.

7. Influence of environmental factors: The environment in which the auxiliary switch is used has an important influence on its connection performance. In harsh environments such as high temperature, high humidity, corrosive gases, etc., special protective measures should be taken, such as the use of high temperature, humidity and corrosion-resistant materials and coatings, as well as increased sealing measures.

8. Regular inspection and maintenance: During the use of auxiliary switches, their connection status should be checked regularly to detect and deal with potential problems in time. For the connection parts that are worn and aged, they should be replaced in time to ensure the long-term stable operation of the system.

In summary, the problems that need to be paid attention to in the connection process of auxiliary switches include connection stability, cable selection and wiring specifications, prevention of electrical noise interference, consideration of delay characteristics, application of double contact characteristics, connection of special contacts, the influence of environmental factors, and regular inspection and maintenance. By paying full attention to these issues and dealing with them properly, it can ensure that the auxiliary switch plays its due role in the power system and improve the reliability and safety of the system.