How auxiliary switches are wired

Release time:2024-08-16

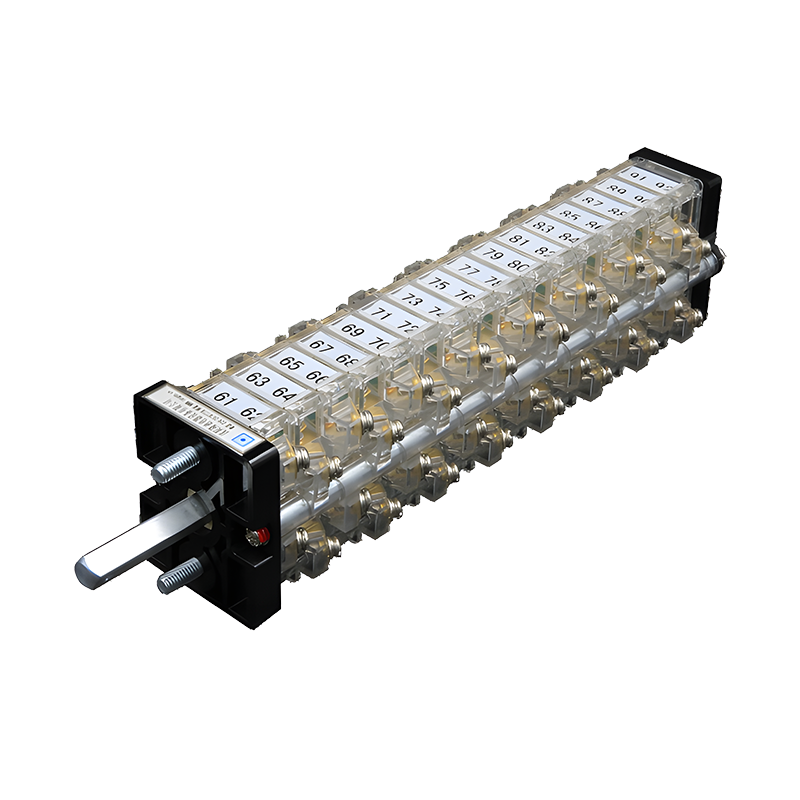

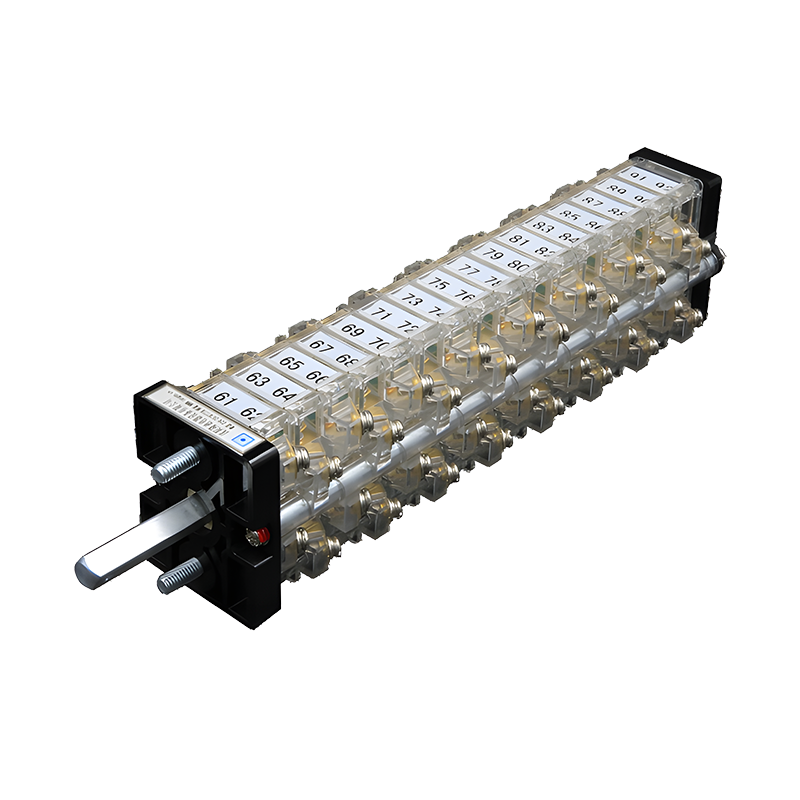

How auxiliary switches are wired is a crucial technical aspect when exploring the complex world of electrical equipment. These switches are often used for control and protection of electrical circuits, and their proper wiring is critical to ensuring stable system operation. This article will take an in-depth look at how auxiliary switches are wired and explain why these steps have a non-negligible impact on the performance and safety of the entire system.

Auxiliary switches, as their name suggests, serve primarily as auxiliary controls. They may be used to start or stop motors, to change the operating status of equipment, or as part of a safety device to prevent potential electrical failures. In order to perform these functions, wiring must be done accurately to ensure that current will flow in the intended path.

Before beginning the wiring process, it is a primary step to verify that the auxiliary switch's specifications match the type of circuit to be controlled. This includes voltage and current ratings as well as the physical size of the switch. Once this is confirmed, the next step is to disconnect the power supply and take the necessary safety measures to avoid the risk of electric shock.

Next, identify the individual terminals of the auxiliary switch. Typically, there will be input terminals for accessing the power supply, output terminals for connecting to loads or control objects, and possibly common terminals for completing the circuit. Each terminal should be clearly labeled for proper wiring.

The actual wiring process should be done according to the wiring diagram or the instructions of the electrical engineer. Strip the wires of the appropriate length of insulation and secure the bare wires to the corresponding terminals using a suitable wiring tool. During this process, ensure that all connections are firm and have good electrical contact to avoid looseness or corrosion, which may affect the performance of the switch.

In addition, for auxiliary switches that require frequent operation, consider using screw terminals or quick terminals to simplify future maintenance. These terminals allow wires to be added or removed easily and quickly without disconnecting other wiring.

After completing the wiring, but before actually putting it into service, it is essential to perform a series of tests. This includes checking the correctness of the wiring, confirming that there are no shorts or breaks, and simulating the operation to ensure that the auxiliary switch is working as intended.

Maintaining a high standard of safety awareness and precision throughout the wiring process is key to safeguarding the reliability of the electrical system. Any negligence can lead to equipment damage or safety incidents, so strict adherence to electrical engineering practices and codes is a basic requirement for every professional engaged in this work.

In summary, the wiring of auxiliary switches requires meticulous attention and specialized technical knowledge. By following the proper steps and precautions, you can ensure that auxiliary switches are utilized in the electrical system as they should be, while keeping the system efficient and safe. This attention to detail is all the more important in an increasingly complex electrical environment.

Translated with DeepL.com (free version)

Auxiliary switches, as their name suggests, serve primarily as auxiliary controls. They may be used to start or stop motors, to change the operating status of equipment, or as part of a safety device to prevent potential electrical failures. In order to perform these functions, wiring must be done accurately to ensure that current will flow in the intended path.

Before beginning the wiring process, it is a primary step to verify that the auxiliary switch's specifications match the type of circuit to be controlled. This includes voltage and current ratings as well as the physical size of the switch. Once this is confirmed, the next step is to disconnect the power supply and take the necessary safety measures to avoid the risk of electric shock.

Next, identify the individual terminals of the auxiliary switch. Typically, there will be input terminals for accessing the power supply, output terminals for connecting to loads or control objects, and possibly common terminals for completing the circuit. Each terminal should be clearly labeled for proper wiring.

The actual wiring process should be done according to the wiring diagram or the instructions of the electrical engineer. Strip the wires of the appropriate length of insulation and secure the bare wires to the corresponding terminals using a suitable wiring tool. During this process, ensure that all connections are firm and have good electrical contact to avoid looseness or corrosion, which may affect the performance of the switch.

In addition, for auxiliary switches that require frequent operation, consider using screw terminals or quick terminals to simplify future maintenance. These terminals allow wires to be added or removed easily and quickly without disconnecting other wiring.

After completing the wiring, but before actually putting it into service, it is essential to perform a series of tests. This includes checking the correctness of the wiring, confirming that there are no shorts or breaks, and simulating the operation to ensure that the auxiliary switch is working as intended.

Maintaining a high standard of safety awareness and precision throughout the wiring process is key to safeguarding the reliability of the electrical system. Any negligence can lead to equipment damage or safety incidents, so strict adherence to electrical engineering practices and codes is a basic requirement for every professional engaged in this work.

In summary, the wiring of auxiliary switches requires meticulous attention and specialized technical knowledge. By following the proper steps and precautions, you can ensure that auxiliary switches are utilized in the electrical system as they should be, while keeping the system efficient and safe. This attention to detail is all the more important in an increasingly complex electrical environment.

Translated with DeepL.com (free version)