Stamping process ribbing techniques: the key to improving product quality and efficiency

In modern manufacturing, stamping is a widely used metal forming process. In the stamping process, the mastery of the press bar technique is crucial for improving product quality, enhancing product performance and improving production efficiency.

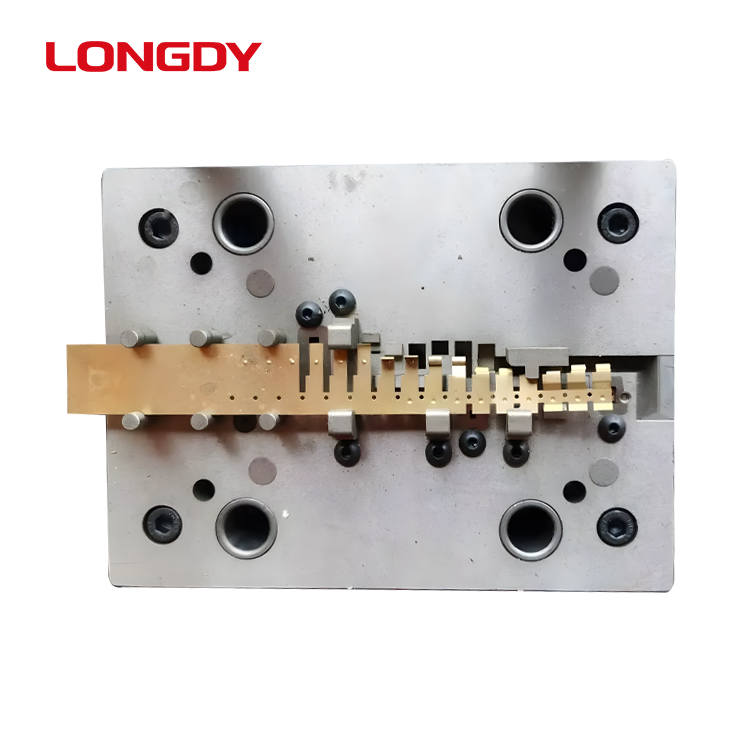

Pressing is an important process in stamping, which forms a raised or depressed bar structure by applying specific pressure on the metal sheet. These bars can not only increase the strength and rigidity of the plate, but also improve the appearance and precision of the product.

1. Impact of the bar pressing technique on product quality

Ⅰ. Enhance structural strength

Pressing rib can significantly improve the bending and torsion resistance of the plate without increasing the thickness of the material. For example, in the manufacture of automobile body, through the key parts of the compression rib, can enhance the overall structural strength of the body, improve the safety and stability of the vehicle.

Ⅱ. Improvement of dimensional accuracy

Precise control of the position, shape and size of the compression rib can effectively reduce the deformation and springback of the plate in the stamping process, thus improving the dimensional accuracy and consistency of the product. This is especially important for some electronic parts and precision instruments that require high precision.

Ⅲ. Improvement of appearance quality

Reasonable design of the pressure rib can make the product surface more flat, smooth, reduce the appearance of surface defects and wrinkles, improve the appearance of product quality, enhance market competitiveness.

2. the ribbing skills for the improvement of production efficiency

Ⅰ. Optimization of mold design

The use of advanced design concepts, combined with computer-aided design (CAD) and computer-aided engineering (CAE) technology, can shorten the mold development cycle, reduce the cost of the mold, improve the service life of the mold and production efficiency.

Ⅱ. Selection of suitable parameters for the press bar process

Including pressure, speed, stroke, etc., according to different materials and product requirements for optimization and adjustment, can reduce the scrap rate and rework times, improve production efficiency.

Ⅲ. Realize automated production

With the help of automated equipment and robotics, to realize the automatic operation of the tendon pressing process, not only can improve production efficiency, but also reduce the error and labor intensity brought about by manual operation.

3. the actual application of ribbing techniques

Ⅰ. Home appliance industry

In the refrigerator, air conditioning and other home appliances shell manufacturing, through the ribbing process to increase the strength and stability of the shell, while making the appearance more beautiful and generous.

Ⅱ. Aerospace field

In the manufacture of aircraft parts, the press bar technique is used to improve the strength and light weight of the parts to ensure flight safety.

Ⅲ. Electronic equipment manufacturing

Cell phones, computers and other electronic products shell and internal structure parts, the use of compression ribbing to enhance the structure and reduce the volume.

In short, the press bar technique in the stamping process is a comprehensive technology, which needs to be combined with the knowledge and experience of material science, mold design, process optimization and other aspects. Mastering the advanced press bar technique can not only bring significant economic benefits for enterprises, but also promote the technological progress and innovative development of the entire manufacturing industry.