Injection molds to extend the life of the secret to reveal!

In the injection molding industry, the life of a mold directly affects productivity and cost. A durable mold not only improves production quality, but also reduces downtime and maintenance costs associated with frequent mold changes. To achieve the goal of extending the service life of the injection mold, you need to start from a number of aspects, including mold design, material selection, processing technology, injection molding process optimization, maintenance and repair, as well as the use of the environment and other aspects.

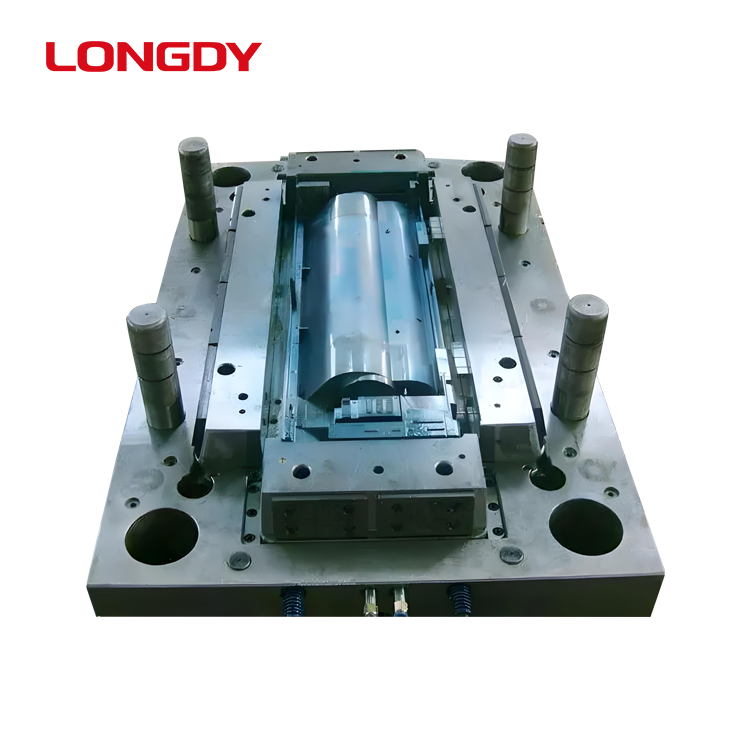

1. Reasonable injection mold design is the basis for extending the life of the mold.

In the early stage of mold design, designers need to select the appropriate mold material and structure according to product requirements and production conditions. This involves not only the rigidity and stability of the mold, but also how to reduce the possibility of stress concentration and wear.

2. High-quality mold materials are essential for improving the wear and corrosion resistance of the mold.

When selecting mold materials, priority should be given to high-performance materials that can withstand high-pressure and high-temperature operating environments. Although these materials are more costly, their excellent wear and high-temperature resistance will significantly enhance the service life of the molds, thereby reducing the overall production costs in the long run.

3. Fine injection mold processing is also an indispensable part of extending the life of the mold.

Through the use of advanced CNC machining equipment and technology, can greatly improve the processing quality and precision, reduce processing errors and deformation. High-precision processing not only ensures the accuracy of the mold dimensions, but also helps to improve the quality of molded products and reduce the workload of post-processing.

4. The optimization of the injection molding process also has an important impact on the life of the mold.

By adjusting the injection process parameters, such as injection speed, pressure, temperature, etc., the stress and wear of the mold can be reduced, reducing mold fatigue and deformation. In addition, a reasonable process can also reduce the retention time of the material inside the mold, reduce the corrosion and wear on the mold.

5. Regular maintenance and repair is the key to ensure long-term stable operation of the mold.

This includes regular cleaning, lubrication and anti-rust treatment of the mold, timely repair and replacement of worn parts. In addition, the establishment of a set of perfect mold management ledger and labeling system can help companies better track and manage the use and maintenance of the mold.

6. The impact of the use of the environment on the life of the mold should not be ignored.

Maintain the appropriate temperature and humidity of the mold environment, reduce vibration and impact, can effectively extend the service life of the mold. In addition, reasonable arrangements for the storage and use of the mold, to avoid excessive use and improper operation, is also an important measure to protect the mold from damage.