Five tips to avoid elastic deformation failure in stamping processing!

During stamping processing, the material undergoes a complex process from elastic deformation to plastic deformation, in which the elastic deformation stage plays a crucial role in the overall processing quality. In this article, we will discuss in depth the elastic deformation stage of stamping processing need to pay attention to several key factors to ensure the quality and performance of the final product.

First, the internal stress state of the material. A certain amount of internal stresses may exist in the material before processing due to various reasons, such as heat treatment and mechanical processing. These internal stresses, if not controlled, will lead to uneven deformation of the material during the stamping process and affect the dimensional accuracy of the part. Therefore, it is necessary to eliminate or adjust the internal stresses of the material through appropriate heat treatment or pre-stress treatment before stamping process.

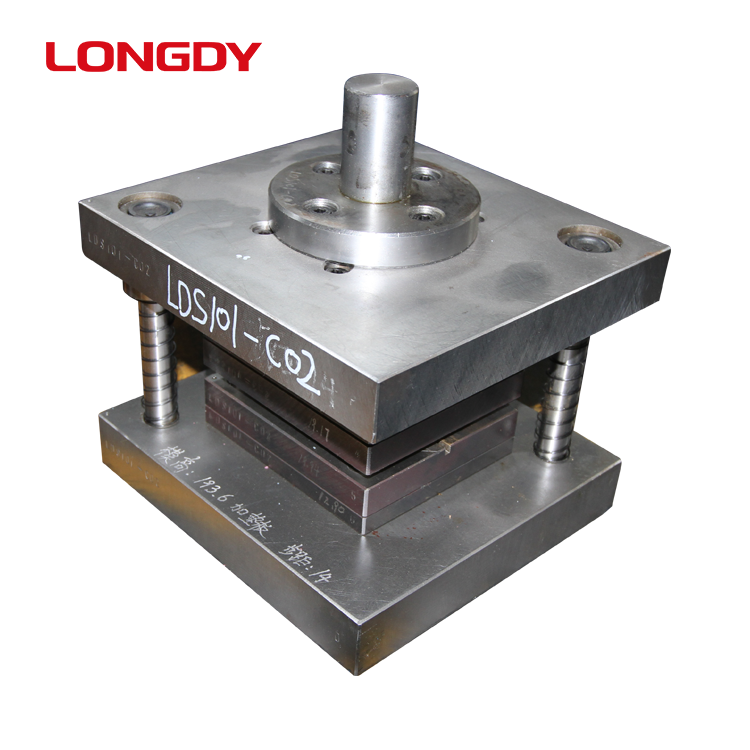

Second, mold design. The design of the die needs to take into account the elastic modulus, yield strength, and hardening index of the material in order to calculate the appropriate die clearance and pressure. In addition, the material selection of the mold is also very important, and materials with high wear resistance and good toughness should be selected to improve the service life of the mold and ensure the stability of processing.

Third, the control of stamping speed and pressure. Too fast a stamping speed will increase the strain rate of the material, resulting in a rise in the local temperature of the material, thus affecting its mechanical properties; while too slow a stamping speed may increase the processing time and reduce productivity. Therefore, it is very important to choose the appropriate stamping speed according to different materials and part requirements. At the same time, reasonable pressure settings can ensure that the material in the elastic deformation stage to get the full effect of pressure, to avoid incomplete deformation due to insufficient pressure or material damage caused by excessive pressure.

Fourth, ambient temperature and lubrication conditions. Changes in ambient temperature affect the elastic modulus and yield strength of the material, thus affecting its deformation behavior. In cold stamping, it is usually necessary to control the temperature of the workshop to ensure the stability of the mechanical properties of the material; while in hot stamping, it is necessary to choose the appropriate heating temperature and holding time according to the characteristics of the material. The optimization of lubrication conditions can reduce the friction between the material and the die, preventing material surface scratches and die wear, and also help to improve the fluidity of the material and reduce the elastic recovery.

Fifth, quality control and inspection. Through real-time monitoring of key parameters in the stamping process, such as pressure, displacement, speed, etc., possible problems can be found and solved in time. Meanwhile, through the use of advanced inspection equipment and methods, accurate size and shape inspection of stamped parts can effectively ensure the qualification rate and consistency of products.