What are the common failures and treatments that microswitches may encounter in rail transit operations?

Release time:2024-07-23

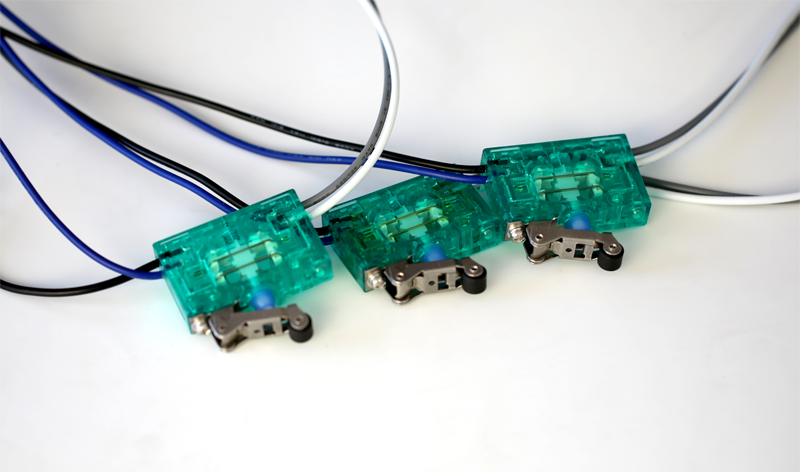

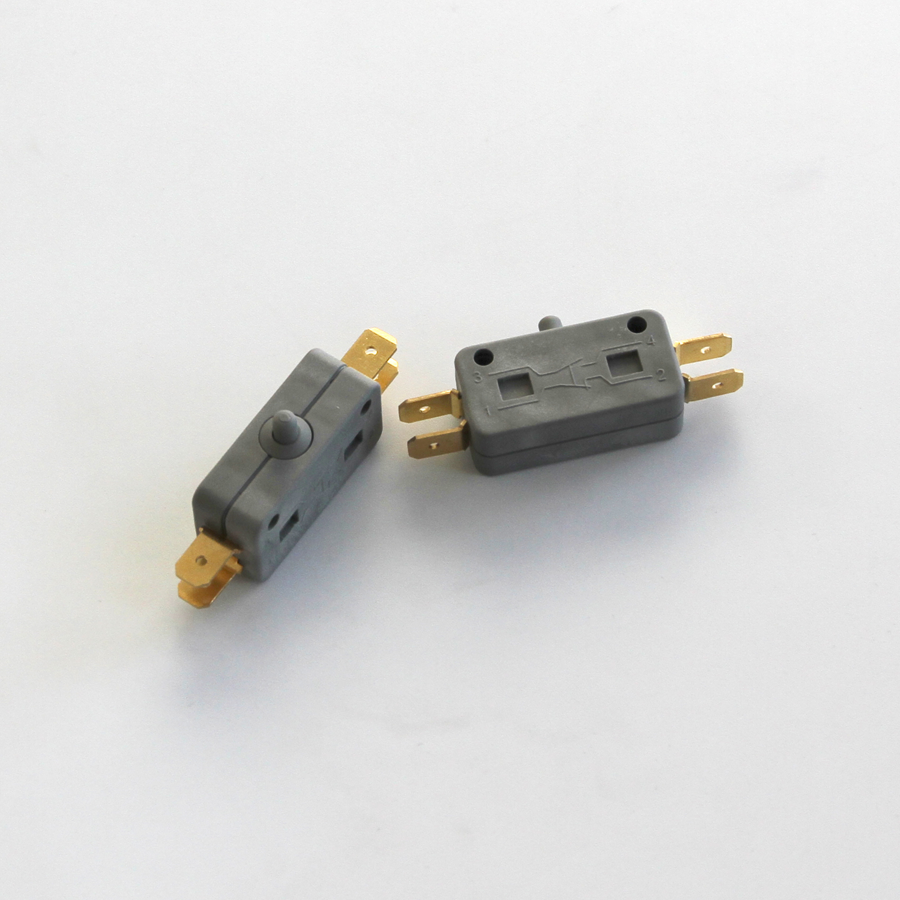

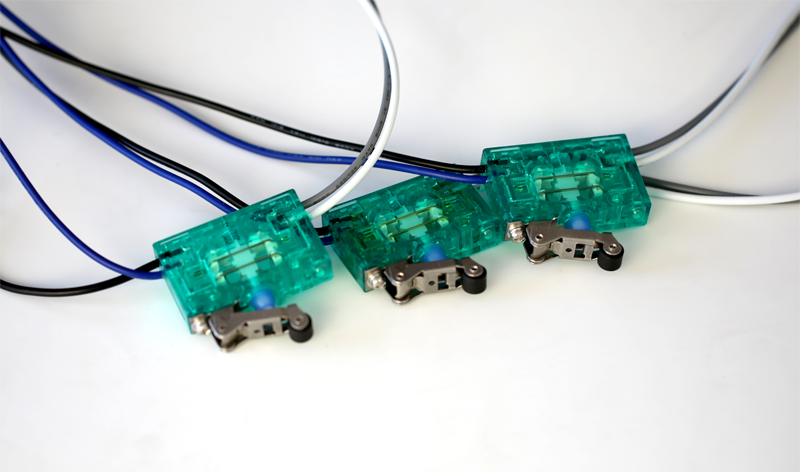

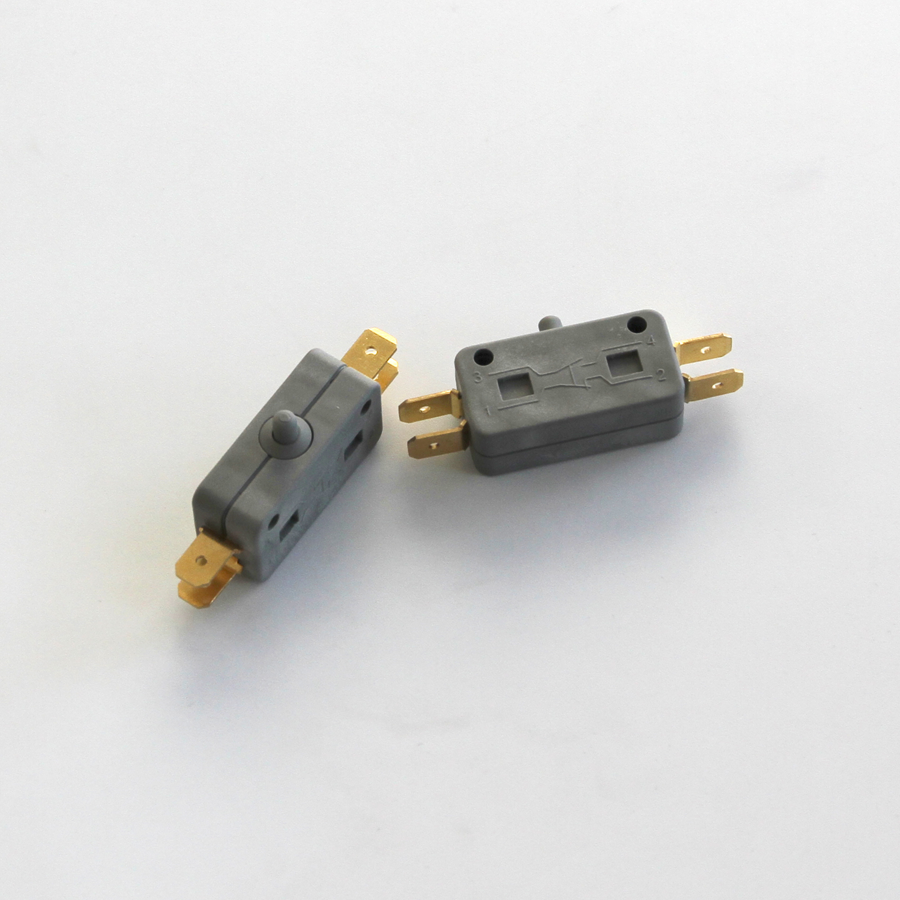

Microswitches play an integral role in rail transit systems. These small, albeit unobtrusive, devices are a critical part of keeping trains running safely and smoothly. However, as with any high-precision device, microswitches can experience a variety of malfunctions over long periods of operation. The following is a discussion of seven common failures and their treatment methods that microswitches may encounter in rail transit operations:

Common Failures and How to Deal with Them

1. Microswitch cannot be activated

Power supply line check: When the switch fails to start, the first thing to check is whether the power supply line is properly connected, which is the most direct and easiest reason to troubleshoot.

Poor contact review: If there is no problem with the power supply, then the fault may lie in poor contact. You can try to remove the switch, clean and check the cleanliness and spacing of the contacts.

Internal Component Failure Determination: If none of the above checks are problematic, then the microswitch may have an internal component failure, such as wear or looseness. It is necessary to disassemble the switch further and replace the damaged parts accordingly.

2. Frequently failing microswitches

External interference source troubleshooting: First of all, you should check whether there is a strong magnetic field, electromagnetic radiation or other interference equipment around the existence of the problem.

Spring wear and poor contact treatment: cleaning contacts and treating springs with lubricating oil can effectively solve the problem of frequent malfunction due to spring wear or poor contact.

Internal dust accumulation or corrosion cleaning: After long-term use, dust may accumulate or corrosion may occur inside the microswitch, at this time, you can clean it with detergent or consider replacing it with a new microswitch.

3. Sparking at the contacts

Supply voltage check: Excessive supply voltage is one of the common causes of contact sparking, which can be measured by a voltmeter and the power supply system can be repaired in time.

Poor contact adjustment: poor contact may also lead to sparks, the contacts should be cleaned and adjusted appropriately.

External load check: Excessive external load may also cause contact sparks, make sure the load is used within the load range of the microswitch.

4. Inaccurate operation

Mounting stability check: A solid mounting is essential to ensure the accuracy of the microswitch. A loose mounting will affect its accuracy.

Force imbalance adjustment: Force imbalance caused by the microswitch lever may also result in inaccurate operation, which can be tested and restored to normal function by gently pressing the lever manually.

Damaged internal parts replacement: If the above methods are ineffective, it may be caused by damaged internal parts, which requires disassembling the switch, checking and replacing the faulty parts.

5. Abnormal noise

Firmness of installation check: Abnormal noise is likely to be caused by poor installation or loose or damaged contacts. It should be checked and necessary tightening or replacement work should be carried out.

Corrosion or dust accumulation cleanup: Micro switches subject to corrosion or accumulation of dust can also cause noise problems and require cleaning and maintenance with detergents.

6. Unable to reset

External interference troubleshooting: Check for debris or other external interference that may have caused the switch to jam, clean it up and try to reset it again.

Damaged Spring Replacement: Damaged spring may cause failure to reset, need to check and replace the spring.

Lost or Broken Lever Reinstallation: If the microswitch lever is lost or broken, the lever needs to be reinstalled or replaced with a new microswitch.

7. Deteriorated sealing performance

Seal replacement: Deteriorated or broken seals need to be replaced to maintain the sealing performance of the microswitch.

Case integrity check: A cracked or deformed case will also affect sealing performance and will need to be inspected and the broken part replaced.

External environment cleaning: Keeping the working environment clean is also an important measure to avoid sealing performance degradation.

In a word, the safe operation of rail transportation can not be separated from the careful maintenance of every detail, and the micro switch as a small part of it, carrying a responsibility that can not be underestimated. Through scientific and standardized maintenance operation, the service life of microswitches can be effectively extended to ensure the safety and smoothness of rail transportation. The safety of every trip originates from the attention and maintenance of these seemingly insignificant but vital details.

Common Failures and How to Deal with Them

1. Microswitch cannot be activated

Power supply line check: When the switch fails to start, the first thing to check is whether the power supply line is properly connected, which is the most direct and easiest reason to troubleshoot.

Poor contact review: If there is no problem with the power supply, then the fault may lie in poor contact. You can try to remove the switch, clean and check the cleanliness and spacing of the contacts.

Internal Component Failure Determination: If none of the above checks are problematic, then the microswitch may have an internal component failure, such as wear or looseness. It is necessary to disassemble the switch further and replace the damaged parts accordingly.

2. Frequently failing microswitches

External interference source troubleshooting: First of all, you should check whether there is a strong magnetic field, electromagnetic radiation or other interference equipment around the existence of the problem.

Spring wear and poor contact treatment: cleaning contacts and treating springs with lubricating oil can effectively solve the problem of frequent malfunction due to spring wear or poor contact.

Internal dust accumulation or corrosion cleaning: After long-term use, dust may accumulate or corrosion may occur inside the microswitch, at this time, you can clean it with detergent or consider replacing it with a new microswitch.

3. Sparking at the contacts

Supply voltage check: Excessive supply voltage is one of the common causes of contact sparking, which can be measured by a voltmeter and the power supply system can be repaired in time.

Poor contact adjustment: poor contact may also lead to sparks, the contacts should be cleaned and adjusted appropriately.

External load check: Excessive external load may also cause contact sparks, make sure the load is used within the load range of the microswitch.

4. Inaccurate operation

Mounting stability check: A solid mounting is essential to ensure the accuracy of the microswitch. A loose mounting will affect its accuracy.

Force imbalance adjustment: Force imbalance caused by the microswitch lever may also result in inaccurate operation, which can be tested and restored to normal function by gently pressing the lever manually.

Damaged internal parts replacement: If the above methods are ineffective, it may be caused by damaged internal parts, which requires disassembling the switch, checking and replacing the faulty parts.

5. Abnormal noise

Firmness of installation check: Abnormal noise is likely to be caused by poor installation or loose or damaged contacts. It should be checked and necessary tightening or replacement work should be carried out.

Corrosion or dust accumulation cleanup: Micro switches subject to corrosion or accumulation of dust can also cause noise problems and require cleaning and maintenance with detergents.

6. Unable to reset

External interference troubleshooting: Check for debris or other external interference that may have caused the switch to jam, clean it up and try to reset it again.

Damaged Spring Replacement: Damaged spring may cause failure to reset, need to check and replace the spring.

Lost or Broken Lever Reinstallation: If the microswitch lever is lost or broken, the lever needs to be reinstalled or replaced with a new microswitch.

7. Deteriorated sealing performance

Seal replacement: Deteriorated or broken seals need to be replaced to maintain the sealing performance of the microswitch.

Case integrity check: A cracked or deformed case will also affect sealing performance and will need to be inspected and the broken part replaced.

External environment cleaning: Keeping the working environment clean is also an important measure to avoid sealing performance degradation.

In a word, the safe operation of rail transportation can not be separated from the careful maintenance of every detail, and the micro switch as a small part of it, carrying a responsibility that can not be underestimated. Through scientific and standardized maintenance operation, the service life of microswitches can be effectively extended to ensure the safety and smoothness of rail transportation. The safety of every trip originates from the attention and maintenance of these seemingly insignificant but vital details.