What do I need to pay attention to for the installation and maintenance of rail transit microswitches?

Release time:2024-07-17

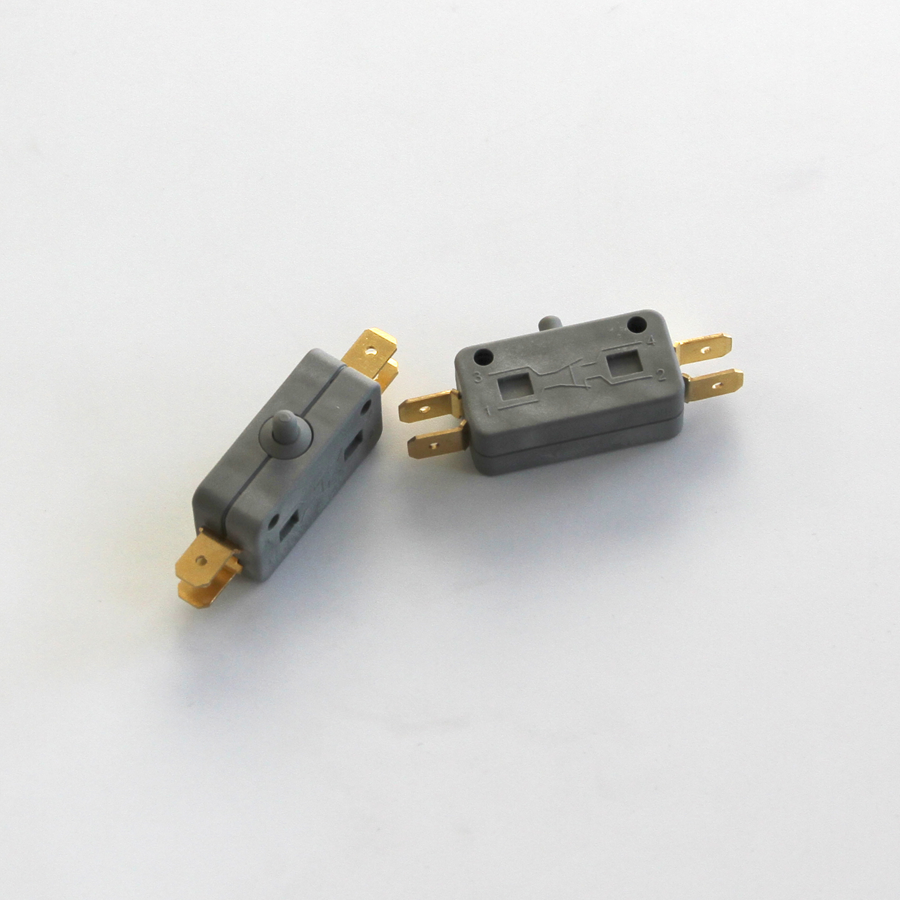

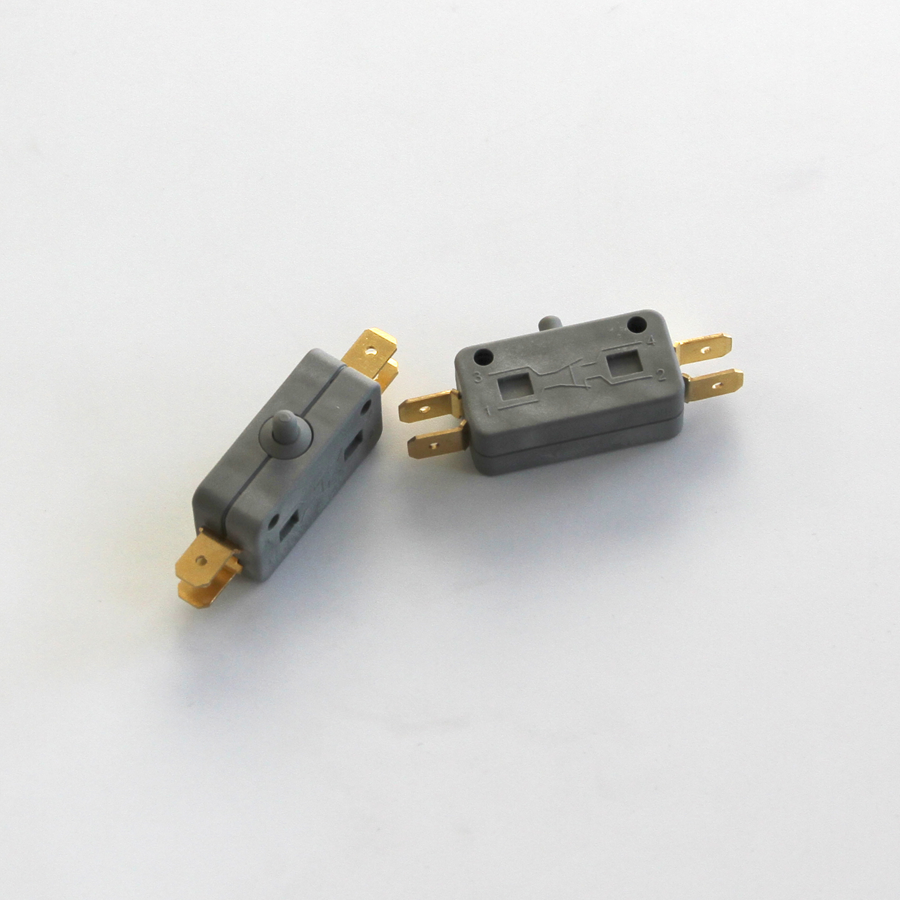

In the vast field of rail transportation, the tacit cooperation of countless precision components is indispensable behind every safe trip. Microswitch, this small and inconspicuous components, but in every journey of the train plays an irreplaceable role. They are like tiny guardians, silently ensuring the smooth operation of the train and the safety of passengers.

I. Installation Precautions

1. Environmental adaptability considerations

In the rail transportation environment, microswitches need to adapt to a variety of external conditions, including underground humidity, ground sand and ultraviolet radiation exposure on viaducts, etc. Therefore, when selecting microswitches, it is important to consider their environmental adaptability. Therefore, when selecting microswitches, it is important to make sure that they are waterproof, dustproof and high temperature resistant.

For example, high-temperature microswitches can work properly in environments up to 250°C, and explosion-proof switches are suitable for places with explosion hazards.

2. Speed of response and size

In the critical moments of train starting and braking, high-speed action microswitches can better meet the demand for immediate transmission of control commands.

At the same time, due to the compact space design of railroad vehicles, microswitches need to be small in size for easy integration and replacement.

3. Cost-benefit ratio

In terms of economics, the purchase cost, operating cost and maintenance cost should be considered to find the most cost-effective microswitch. The concept of Total Cost of Ownership guides us in making decisions that take into account both short-term inputs and long-term maintenance costs.

4. Reliability First

Any small mistake can have immeasurable consequences. Therefore, microswitches must be carefully screened for durability, immunity to interference, and failure rate.

Second, maintenance methods in detail

1. Regular inspection

According to the specific use environment and frequency, regular external cleaning and internal structure inspection of microswitches are carried out to ensure the normal operation of the switches.

For example, a quarterly inspection plan can be made, focusing on the degree of wear and tear of switch contacts and connection fastening.

2. Preventing dust accumulation

After long-term use, microswitches may accumulate dust, debris or oil, which may affect their normal triggering and operation. It should be cleaned and maintained in time to avoid malfunction.

You can use anhydrous alcohol or cotton swabs to gently clean the contact assembly and switch surface to keep them clean and in good contact.

3. Fastening parts inspection

The fastening parts of the microswitch should be in proper position to ensure that they are fixed reliably to avoid malfunctioning due to vibration or loosening.

It is recommended to check the tightness of the screws and fixtures periodically (e.g., once a month) and re-tighten or replace worn-out fasteners promptly if necessary.

4. Circuit Maintenance

When the microswitch malfunctions for timely maintenance, it is necessary to check whether there are any problems such as short circuit or broken circuit, and to replace the worn parts regularly to ensure the long-term stable operation of the microswitch.

For switches that work frequently, consider establishing a detailed maintenance record and replacing obviously worn parts each time maintenance is performed to ensure their optimal working condition.

In summary, through the scientific specification of installation and maintenance, we can effectively extend the service life of microswitches and guarantee the safe operation of rail transportation. Every detail should not be taken lightly, only in this way can we ensure that this little switch plays the most critical role at the critical moment.

Translated with DeepL.com (free version)

I. Installation Precautions

1. Environmental adaptability considerations

In the rail transportation environment, microswitches need to adapt to a variety of external conditions, including underground humidity, ground sand and ultraviolet radiation exposure on viaducts, etc. Therefore, when selecting microswitches, it is important to consider their environmental adaptability. Therefore, when selecting microswitches, it is important to make sure that they are waterproof, dustproof and high temperature resistant.

For example, high-temperature microswitches can work properly in environments up to 250°C, and explosion-proof switches are suitable for places with explosion hazards.

2. Speed of response and size

In the critical moments of train starting and braking, high-speed action microswitches can better meet the demand for immediate transmission of control commands.

At the same time, due to the compact space design of railroad vehicles, microswitches need to be small in size for easy integration and replacement.

3. Cost-benefit ratio

In terms of economics, the purchase cost, operating cost and maintenance cost should be considered to find the most cost-effective microswitch. The concept of Total Cost of Ownership guides us in making decisions that take into account both short-term inputs and long-term maintenance costs.

4. Reliability First

Any small mistake can have immeasurable consequences. Therefore, microswitches must be carefully screened for durability, immunity to interference, and failure rate.

Second, maintenance methods in detail

1. Regular inspection

According to the specific use environment and frequency, regular external cleaning and internal structure inspection of microswitches are carried out to ensure the normal operation of the switches.

For example, a quarterly inspection plan can be made, focusing on the degree of wear and tear of switch contacts and connection fastening.

2. Preventing dust accumulation

After long-term use, microswitches may accumulate dust, debris or oil, which may affect their normal triggering and operation. It should be cleaned and maintained in time to avoid malfunction.

You can use anhydrous alcohol or cotton swabs to gently clean the contact assembly and switch surface to keep them clean and in good contact.

3. Fastening parts inspection

The fastening parts of the microswitch should be in proper position to ensure that they are fixed reliably to avoid malfunctioning due to vibration or loosening.

It is recommended to check the tightness of the screws and fixtures periodically (e.g., once a month) and re-tighten or replace worn-out fasteners promptly if necessary.

4. Circuit Maintenance

When the microswitch malfunctions for timely maintenance, it is necessary to check whether there are any problems such as short circuit or broken circuit, and to replace the worn parts regularly to ensure the long-term stable operation of the microswitch.

For switches that work frequently, consider establishing a detailed maintenance record and replacing obviously worn parts each time maintenance is performed to ensure their optimal working condition.

In summary, through the scientific specification of installation and maintenance, we can effectively extend the service life of microswitches and guarantee the safe operation of rail transportation. Every detail should not be taken lightly, only in this way can we ensure that this little switch plays the most critical role at the critical moment.

Translated with DeepL.com (free version)