How to choose the right microswitch model?

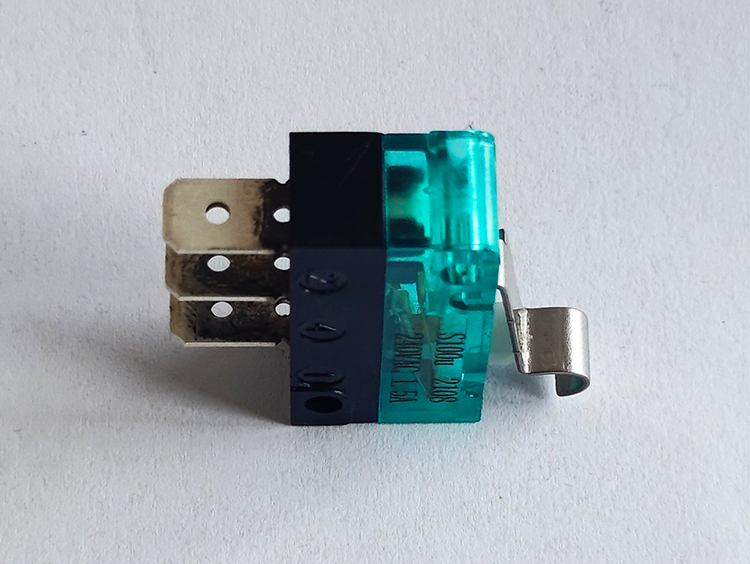

Size matters when selecting a microswitch. Switch size is directly related to its characteristics, including current range, travel, and operating force. For example, one of the smallest microswitches on the market today measures 0.50 inches x 0.236 inches x 0.197 inches (LxWxH). While this tiny switch is suitable for use in compact circuit breakers for detecting circuit status, it is typically capable of interrupting only 0.1 to 3 amps (A) and has a short stroke. Applications requiring higher currents usually require larger switches. For example, a microswitch used to detect liquid level in a tank application would need to be able to provide a large stroke and withstand high currents. Often in level switch applications, the switch is used to directly drive a pump and carry a high current. This requires a large microswitch rated at 20A or 25A at 125VAC or 250VAC. Tip: The smaller the switch size, the less travel and current it can break.

Engineers should also be aware of the switch's differential travel-the distance between the switch's trip position and reset position. Its threshold will vary depending on the application. For example, in a temperature switch application, the on/off operating points should be as close as possible and the differential travel should be as low as 0.0001 in. In level pump applications, however, differential travel that is too close may cause the make-up pump to start and stop too frequently, shortening the life of the pump.

Microswitches are typically capable of breaking currents from 5mA/5VDC to 25A/250VAC. The microswitch product line offers a range of products from low energy to power load electrical types for a variety of applications. Engineers must know the current and voltage ratings (AC or DC) required for a specific application in order to select the proper switch. Since a wide range of equipment in all industries is committed to low energy consumption, microswitches must be able to operate at low currents (logic level loads) and DC voltages. However, there are applications that require switches capable of breaking high currents and high voltages, such as industrial grade pump applications. In addition to the load requirements, engineers must select the appropriate circuitry. Switching contacts must be either normally open (NO) or normally closed (NC). With NO contacts, no current normally passes between the contacts. When the switch is actuated, the contacts close and the circuit is open. For NC type contacts, there is normally current passing between the contacts. When the switch is actuated, the contacts open and the circuit is broken.

Environmental requirements can have a significant impact on the selection of microswitches, especially in applications such as industrial controls, medical devices, and other applications that require high reliability and criticality. Understanding the environmental conditions of the application includes airborne contaminants that may enter the switch, the liquid in which the switch is exposed, and operating temperature requirements. For applications in harsh environmental conditions, you need to select a sealed switch with a wide operating temperature range. Highly reliable microswitches can operate in temperatures ranging from -65 degrees F (-54 degrees C) to 350 degrees F (177 degrees C), making it easy to handle a variety of applications. It is also important to note that the switches should be rated at least IP67 for protection against liquid ingress. This eliminates the need to spend a lot of time designing an enclosure with the same level of protection.

The reliability of the switch is critical. You need to be clear about how many electrical and mechanical operational lifetimes are required for an application. Different switches have different contact materials, housings and terminals to meet the electrical and mechanical life requirements of different applications. A highly reliable microswitch can be operated 10 to 20 million times before mechanical failure, and 50,000 to 100,000 times under maximum load before electrical failure. As for the subtle price differences between different quality switches, you need to consider the total cost of use. Because you're not just paying for the switch, you're also paying for the assurance that the switch will operate trouble-free for a long time. In many cases, the additional cost of using a more reliable switch is offset by its lower warranty cost over the course of its use.