The key to rail transportation safety: the way to choose microswitches

Release time:2024-07-11

In the field of rail transportation, safety is always the primary consideration. The smooth running of every train and the safe arrival of every passenger are inseparable from the collaborative work of countless precision devices behind. Among these devices, microswitches, though small, carry a huge safety responsibility. How to ensure that the microswitches purchased meet the safety requirements of rail transportation? This is not only a technical issue, but also a reflection of the responsibility for life.

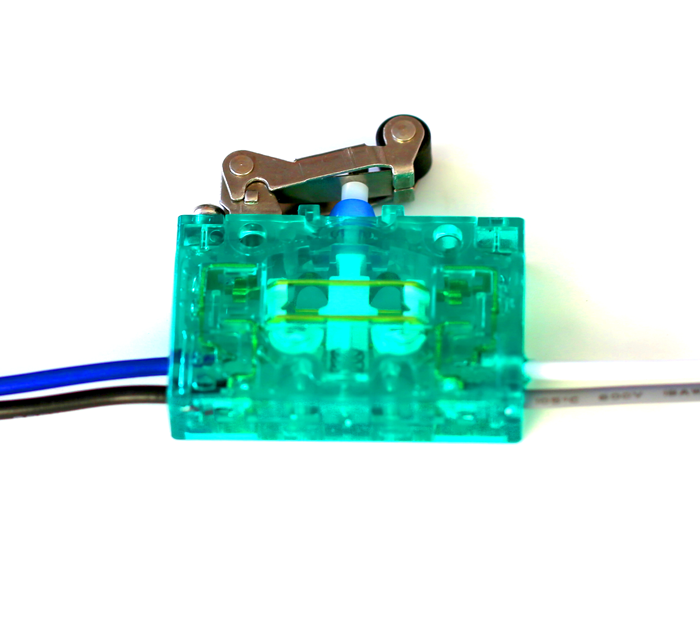

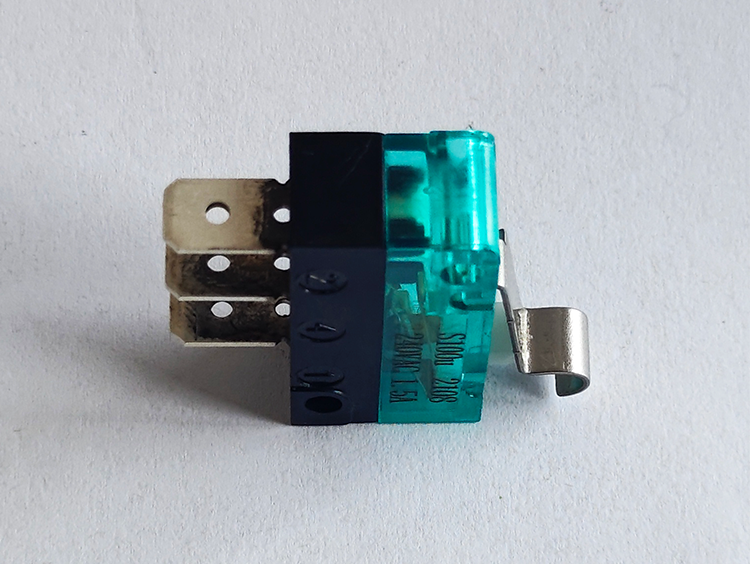

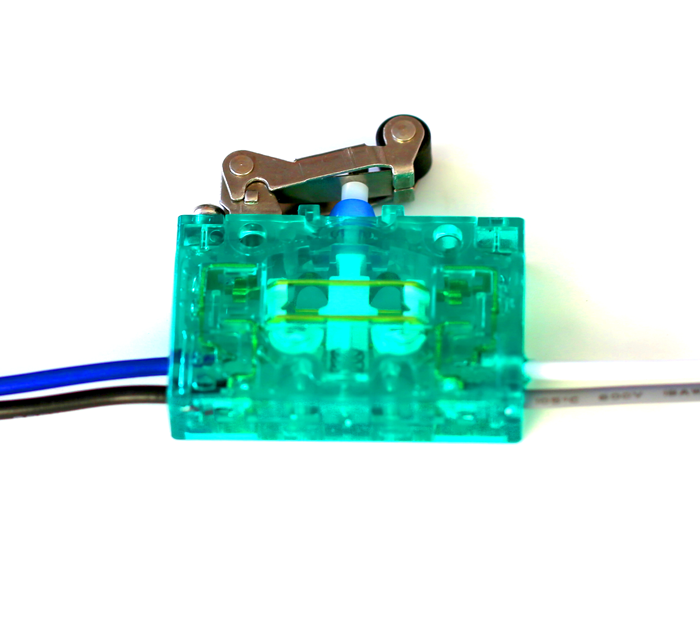

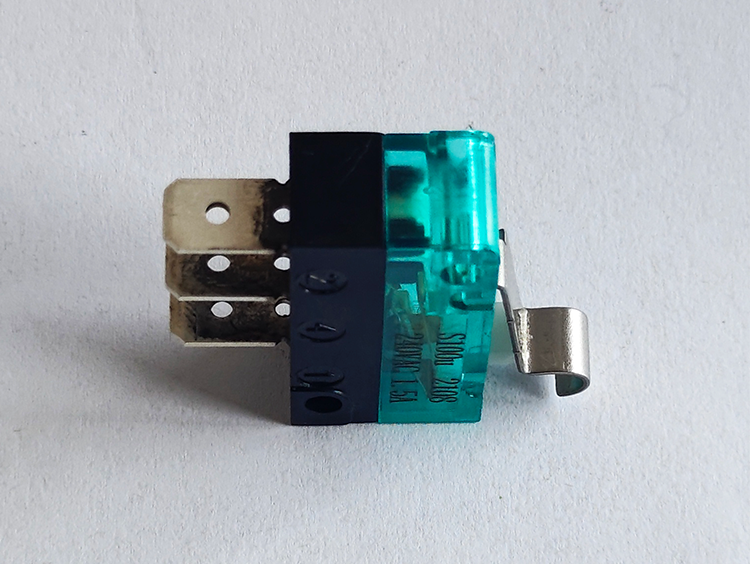

Micro switch, as the name suggests, is a kind of switch that can be triggered by a small action. In rail transportation, it is commonly used in door control, emergency braking system, anti-skid device and other critical parts. Once the microswitch fails, it may lead to the door not being able to open or close normally, or even cause the emergency brake to fail, the consequences are unimaginable. Therefore, it is crucial to purchase microswitches that are suitable for rail transportation safety.

We need to clarify the basic requirements of rail transportation for microswitches. These requirements usually include, but are not limited to, high reliability, long life, vibration resistance, resistance to temperature and humidity changes, etc.. Reliability means that the microswitch needs to keep working under extreme conditions; long life ensures stability in long-term operation; and resistance to vibration and changes in temperature and humidity takes into account the special environment of rail transportation.

Understand the technical parameters and performance indicators of microswitches. This includes contact material, action strength, electrical life, mechanical life, protection level and so on. The contact material should be able to withstand frequent operation without wear and tear; the action force should be moderate to ensure sensitive response without false triggering; the longer the electrical and mechanical life, the lower the maintenance cost; and the protection level is directly related to the switch's ability to adapt to harsh environmental conditions.

Choose a manufacturer with good reputation and rich experience. These manufacturers usually have strict quality control systems and are able to provide product certifications that comply with industry standards, such as ISO certification and CE marking. They will also be able to provide detailed product test reports and case studies to prove the applicability of their products in the rail transportation field.

During the selection process, it is indispensable to conduct actual application tests. This can be done by simulating the actual working environment of rail transportation and examining the performance of microswitches in all aspects. The test should cover the switch's response time, durability, and stability under different temperature, humidity, and vibration conditions.

We should also not neglect the later maintenance and after-sales service. Even the highest quality microswitches require regular inspection and maintenance. Choosing a supplier who can provide quick response and professional service will greatly reduce the risks associated with switch failures.

Selecting a microswitch that meets the safety requirements of rail transportation is a systematic project that requires an in-depth understanding of the switch's technical characteristics, careful selection of the manufacturer, rigorous application testing, and a well-established maintenance system. Only in this way can we ensure that this small switch can play its due role in the big issue of safeguarding rail transportation safety.

Micro switch, as the name suggests, is a kind of switch that can be triggered by a small action. In rail transportation, it is commonly used in door control, emergency braking system, anti-skid device and other critical parts. Once the microswitch fails, it may lead to the door not being able to open or close normally, or even cause the emergency brake to fail, the consequences are unimaginable. Therefore, it is crucial to purchase microswitches that are suitable for rail transportation safety.

We need to clarify the basic requirements of rail transportation for microswitches. These requirements usually include, but are not limited to, high reliability, long life, vibration resistance, resistance to temperature and humidity changes, etc.. Reliability means that the microswitch needs to keep working under extreme conditions; long life ensures stability in long-term operation; and resistance to vibration and changes in temperature and humidity takes into account the special environment of rail transportation.

Understand the technical parameters and performance indicators of microswitches. This includes contact material, action strength, electrical life, mechanical life, protection level and so on. The contact material should be able to withstand frequent operation without wear and tear; the action force should be moderate to ensure sensitive response without false triggering; the longer the electrical and mechanical life, the lower the maintenance cost; and the protection level is directly related to the switch's ability to adapt to harsh environmental conditions.

Choose a manufacturer with good reputation and rich experience. These manufacturers usually have strict quality control systems and are able to provide product certifications that comply with industry standards, such as ISO certification and CE marking. They will also be able to provide detailed product test reports and case studies to prove the applicability of their products in the rail transportation field.

During the selection process, it is indispensable to conduct actual application tests. This can be done by simulating the actual working environment of rail transportation and examining the performance of microswitches in all aspects. The test should cover the switch's response time, durability, and stability under different temperature, humidity, and vibration conditions.

We should also not neglect the later maintenance and after-sales service. Even the highest quality microswitches require regular inspection and maintenance. Choosing a supplier who can provide quick response and professional service will greatly reduce the risks associated with switch failures.

Selecting a microswitch that meets the safety requirements of rail transportation is a systematic project that requires an in-depth understanding of the switch's technical characteristics, careful selection of the manufacturer, rigorous application testing, and a well-established maintenance system. Only in this way can we ensure that this small switch can play its due role in the big issue of safeguarding rail transportation safety.