Analysis of the production cycle of customized medical plastic parts processing

Release time:2024-06-26

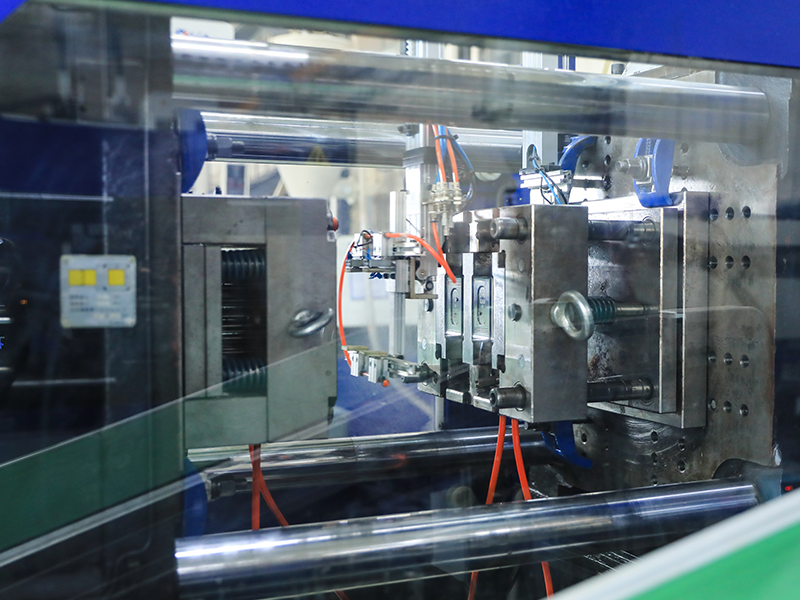

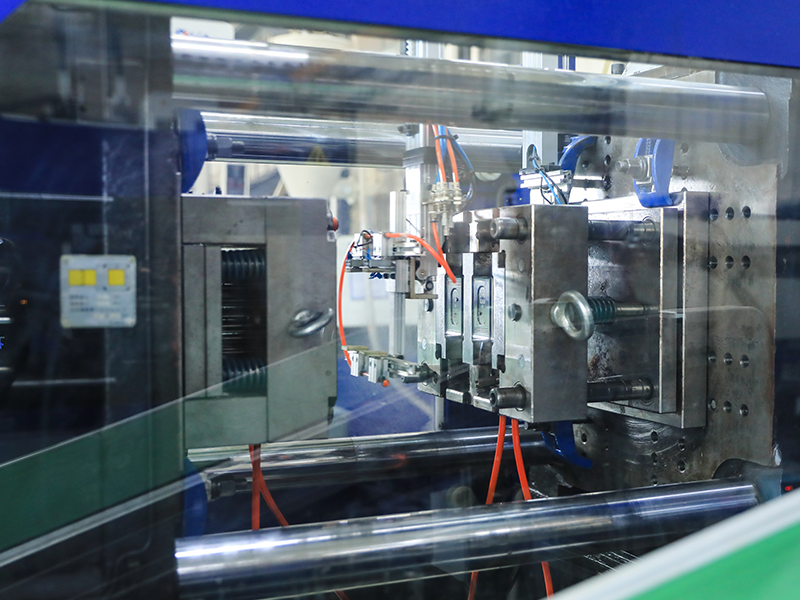

Plastic parts play a critical role in today's rapidly evolving medical industry. From surgical instruments to diagnostic equipment to everyday care products, medical plastic parts are everywhere. However, the process of customizing these sophisticated and complex components is not an easy one. So what is the typical production cycle time for customized medical plastic parts? We'll take you on a deeper dive into the process and reveal the secrets behind the timing.

First, let's be clear: custom medical plastic parts are not a standardized process. Each project has its own unique requirements and challenges, so production lead times will vary depending on the complexity of the project, the uniqueness of the design, the type of materials required, and the manufacturing process. However, despite these variables, we can still generalize a general range of production lead times.

Ideally, a simple custom medical plastic part project can take anywhere from a few weeks to a few months to complete. This includes the initial discussion of the design, the creation of detailed drawings, the creation of molds, the testing of samples, and the production of the final product. For more complex or larger projects, such as those involving multiple components or requiring special processes, the production lead time may extend to six months or even longer.

Please note, however, that the above times are only estimates and the actual production lead time may vary due to a number of factors. For example, if the customer suggests changes to the initial design or if adjustments are found to be necessary during the production process, this may lead to an extension of the production cycle. In addition, the efficiency of the supply chain, the arrangement of production capacity and the stringency of quality control may also have an impact on the production cycle.

Here, we would like to emphasize in particular that although the length of the production cycle is critical to the success of the project, as part of the medical industry, we must not sacrifice the quality of our products in the pursuit of speed. Each medical plastic part is directly related to the health and life safety of patients, so we must ensure that each product is rigorously tested and verified to meet the highest quality standards.

To summarize, the production cycle for customized medical plastic parts processing usually ranges from a few weeks to a few months, depending on the complexity of the project and various external factors. During this seemingly long wait, every step of the process is carefully planned and executed, designed to ensure that each product meets the highest requirements of the medical industry. So when we ask about the production cycle, we are actually exploring a profound topic about quality, responsibility and the dignity of life.

First, let's be clear: custom medical plastic parts are not a standardized process. Each project has its own unique requirements and challenges, so production lead times will vary depending on the complexity of the project, the uniqueness of the design, the type of materials required, and the manufacturing process. However, despite these variables, we can still generalize a general range of production lead times.

Ideally, a simple custom medical plastic part project can take anywhere from a few weeks to a few months to complete. This includes the initial discussion of the design, the creation of detailed drawings, the creation of molds, the testing of samples, and the production of the final product. For more complex or larger projects, such as those involving multiple components or requiring special processes, the production lead time may extend to six months or even longer.

Please note, however, that the above times are only estimates and the actual production lead time may vary due to a number of factors. For example, if the customer suggests changes to the initial design or if adjustments are found to be necessary during the production process, this may lead to an extension of the production cycle. In addition, the efficiency of the supply chain, the arrangement of production capacity and the stringency of quality control may also have an impact on the production cycle.

Here, we would like to emphasize in particular that although the length of the production cycle is critical to the success of the project, as part of the medical industry, we must not sacrifice the quality of our products in the pursuit of speed. Each medical plastic part is directly related to the health and life safety of patients, so we must ensure that each product is rigorously tested and verified to meet the highest quality standards.

To summarize, the production cycle for customized medical plastic parts processing usually ranges from a few weeks to a few months, depending on the complexity of the project and various external factors. During this seemingly long wait, every step of the process is carefully planned and executed, designed to ensure that each product meets the highest requirements of the medical industry. So when we ask about the production cycle, we are actually exploring a profound topic about quality, responsibility and the dignity of life.