Causes of Microswitch Stalling

Release time:2024-06-18

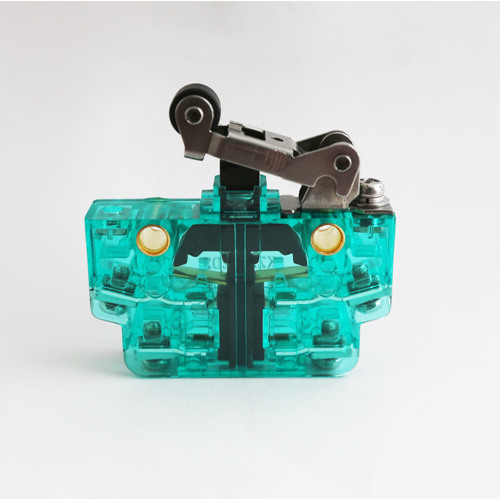

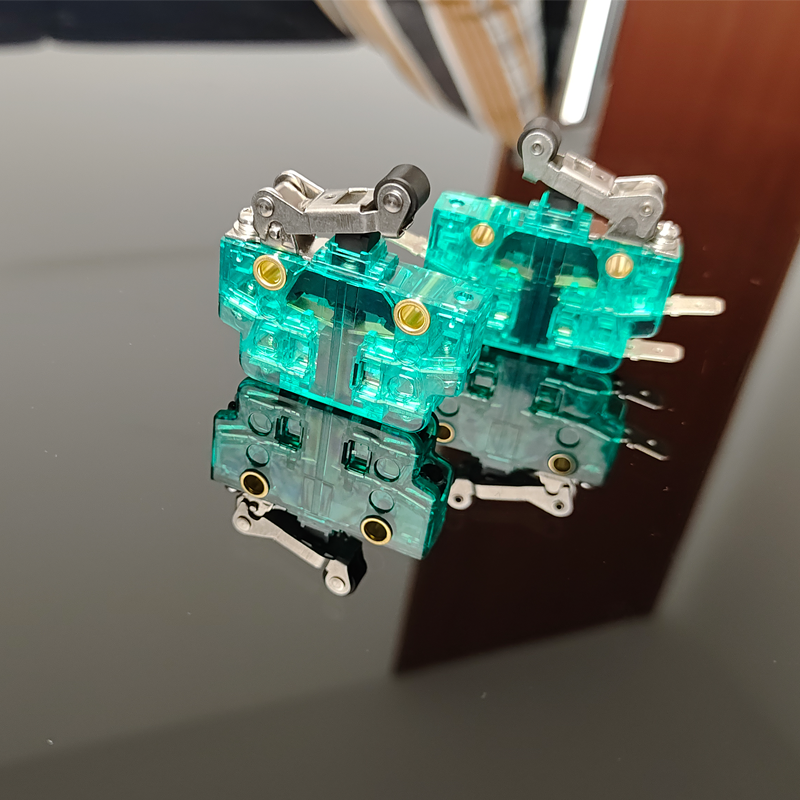

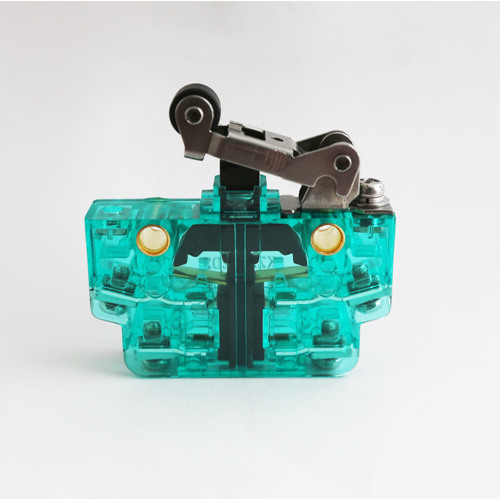

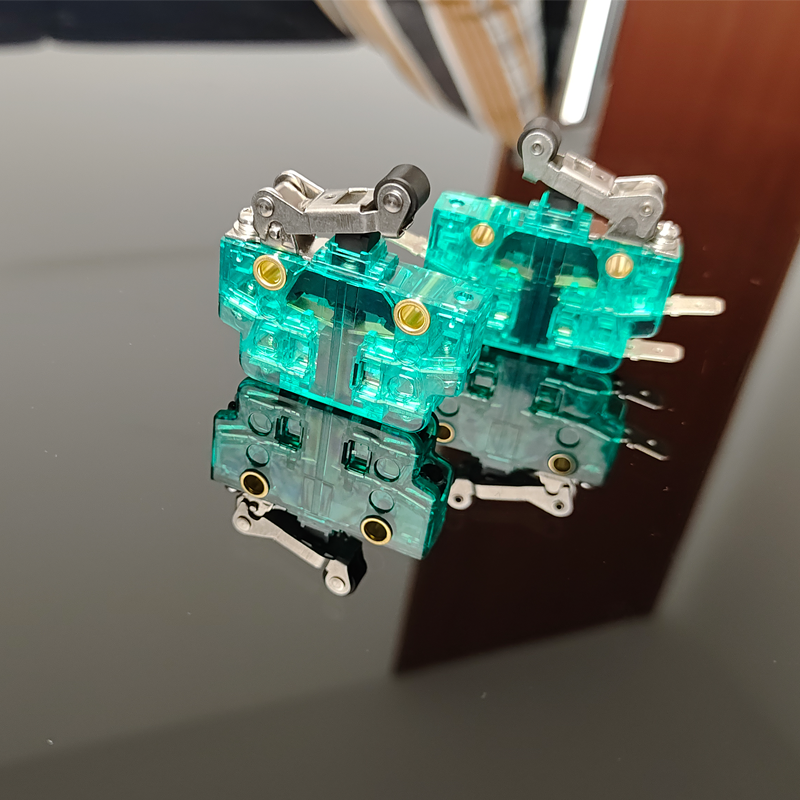

The microswitch plays a vital role in the operation of precision equipment. It is small and sensitive, and is often the gatekeeper of control circuits. However, when this tiny component becomes stuck, the smooth operation of the entire system can be affected. So, what causes the stalling of microswitches? Let's explore the secrets behind this phenomenon.

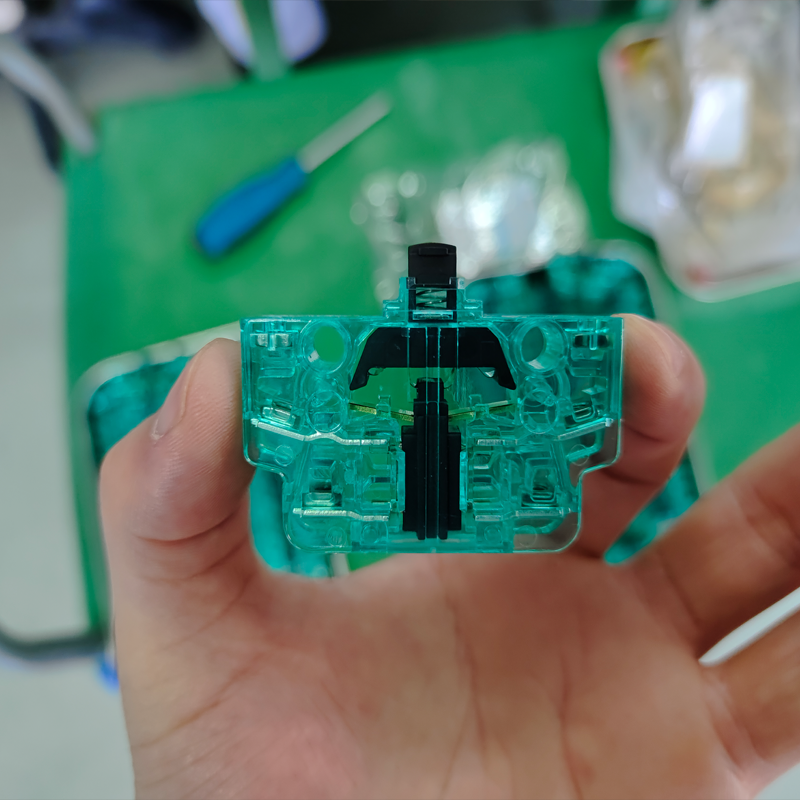

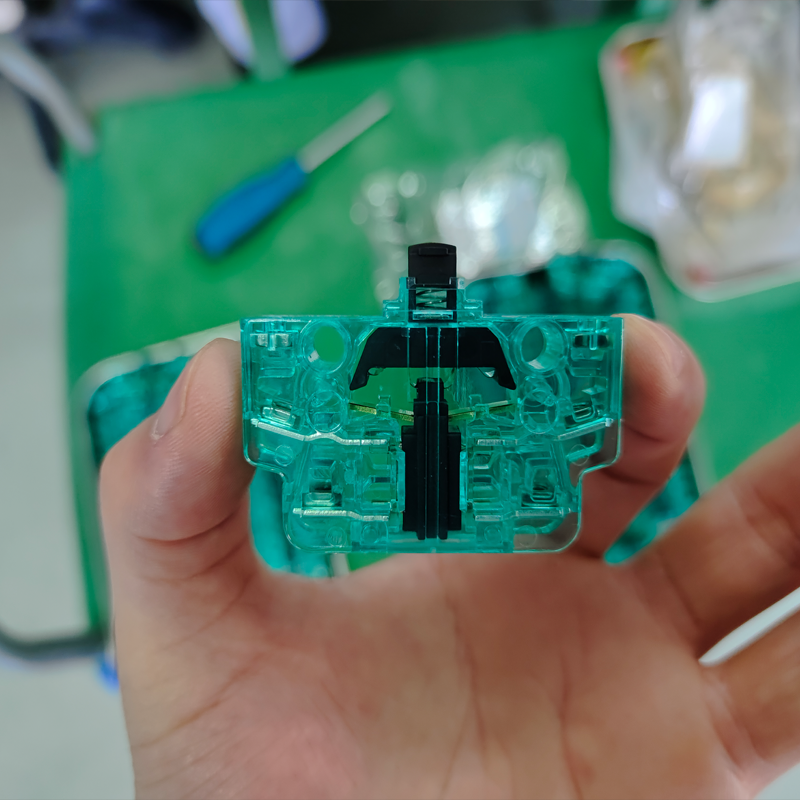

The working principle of a microswitch is based on the elastic force of the internal spring and the precise fit of the contact piece. When an external force is applied to the switch button, the internal contact piece will close or break, thus completing the connection or disconnection of the circuit. This seemingly simple process requires a high degree of precision and stability.

The phenomenon of hysteresis often occurs due to the following reasons:

1. Material fatigue: Repeated operation over a long period of time can cause the spring material inside the switch to become fatigued and less elastic, failing to provide enough force to ensure the rapid action of the contact tabs, thus leading to hysteresis.

2. Pollution accumulation: The intrusion of pollutants such as dust and oil will form an obstruction between the contact piece and the spring, affecting their normal movement and causing stalling.

3. Deformation of the contact plate: long-term mechanical wear or improper operation strength may cause small deformation of the contact plate, this deformation is enough to affect its cooperation with the spring, causing stalling.

4. Environmental factors: Changes in temperature and humidity can affect the expansion and contraction of materials, which, in the case of highly precise microswitches, can lead to minor displacements of the internal structure, thus triggering hysteresis.

5. Design defects: If the design of a microswitch does not fully take into account the usage environment and operating habits, it may also lead to hysteresis during the use of the switch.

In the face of the stalling problem of microswitches, we not only need to understand its causes, but also should take corresponding preventive measures. Regular cleaning and maintenance, reasonable use of strength, and control of environmental factors are the keys to ensure the smooth operation of microswitches. At the same time, choosing high-quality, well-designed microswitch products is also an effective way to prevent stalling.

In this era of increasingly sophisticated technology, the microswitch, though small, carries a huge responsibility. Its smooth operation is not only the guarantee of product quality, but also the respect of user experience. Let's pay attention to the health of microswitches and maintain those silent but indispensable little guardians.

The working principle of a microswitch is based on the elastic force of the internal spring and the precise fit of the contact piece. When an external force is applied to the switch button, the internal contact piece will close or break, thus completing the connection or disconnection of the circuit. This seemingly simple process requires a high degree of precision and stability.

The phenomenon of hysteresis often occurs due to the following reasons:

1. Material fatigue: Repeated operation over a long period of time can cause the spring material inside the switch to become fatigued and less elastic, failing to provide enough force to ensure the rapid action of the contact tabs, thus leading to hysteresis.

2. Pollution accumulation: The intrusion of pollutants such as dust and oil will form an obstruction between the contact piece and the spring, affecting their normal movement and causing stalling.

3. Deformation of the contact plate: long-term mechanical wear or improper operation strength may cause small deformation of the contact plate, this deformation is enough to affect its cooperation with the spring, causing stalling.

4. Environmental factors: Changes in temperature and humidity can affect the expansion and contraction of materials, which, in the case of highly precise microswitches, can lead to minor displacements of the internal structure, thus triggering hysteresis.

5. Design defects: If the design of a microswitch does not fully take into account the usage environment and operating habits, it may also lead to hysteresis during the use of the switch.

In the face of the stalling problem of microswitches, we not only need to understand its causes, but also should take corresponding preventive measures. Regular cleaning and maintenance, reasonable use of strength, and control of environmental factors are the keys to ensure the smooth operation of microswitches. At the same time, choosing high-quality, well-designed microswitch products is also an effective way to prevent stalling.

In this era of increasingly sophisticated technology, the microswitch, though small, carries a huge responsibility. Its smooth operation is not only the guarantee of product quality, but also the respect of user experience. Let's pay attention to the health of microswitches and maintain those silent but indispensable little guardians.