Deformation Characteristics of Stamping Processed Bent Parts

Release time:2024-06-04

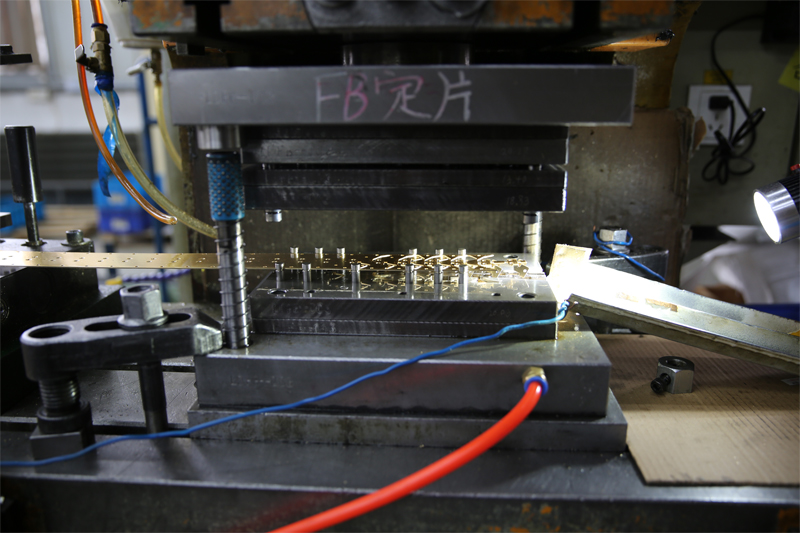

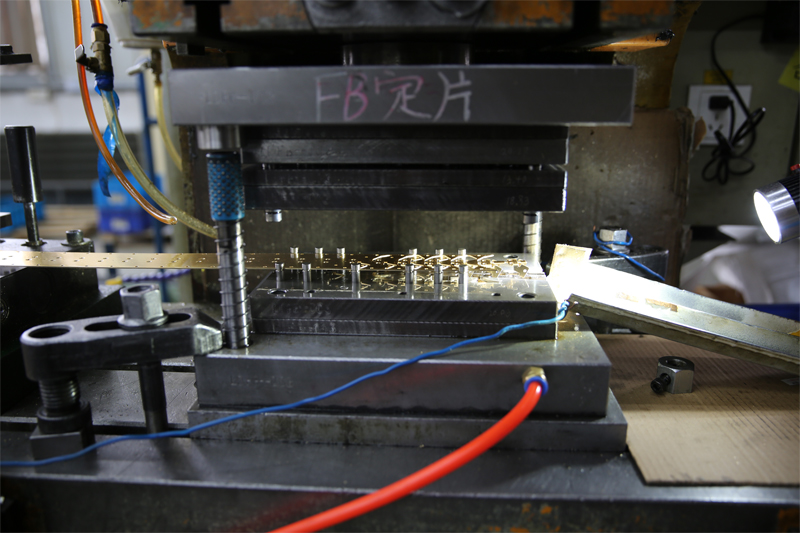

In the field of metal processing, stamping processing is a common manufacturing process, which molds metal materials into desired shapes by applying pressure. And in stamping processing, the deformation characteristics of bent parts is a very important aspect, which directly affects the quality, performance and appearance of the product. In this article, we will introduce the deformation characteristics of bent parts in stamping processing in detail to help readers better understand this process.

First of all, we need to understand what is a bent part. A bent part is a part that bends a metal material into a certain angle and shape through stamping processing. Such parts are widely used in many industries, such as automotive, aviation, home appliances and so on. The deformation characteristics of bent parts mainly include the following aspects:

1. Bending angle: the bending angle of a bent part refers to the angle at which the metal material is bent during the stamping process. The size of this angle directly affects the shape and size of the bent part. In actual production, the control of the bending angle needs to be very precise to ensure the quality and performance of the product.

2. Bending radius: The bending radius is the radius of the inner arc of the bent part of the bent part. The size of this radius affects the strength and stiffness of the bent part. Generally speaking, the smaller the bending radius, the higher the strength and stiffness of the bent part, but it will also increase the stress concentration of the material, which can easily lead to cracks.

3. Rebound: In the stamping process, the metal material will undergo elastic deformation. When the external force disappears, the material will try to restore the original shape, this phenomenon is called rebound. Rebound phenomenon will affect the precision and stability of the bent parts, so it needs to be controlled in the production process.

4. Material thickness: the material thickness of the bent part will also affect its deformation characteristics. In general, the greater the thickness of the material, the higher the strength and stiffness of the bent parts, but also reduces the plasticity of the material, increasing the processing difficulty. Therefore, the choice of material needs to be weighed according to the actual needs.

5. Material type: different types of metal materials have different mechanical properties and plasticity, which will also affect the deformation characteristics of the bent parts. For example, the plasticity of stainless steel material is poor, easy to produce cracks; while the plasticity of aluminum material is better, but lower strength. Therefore, in the selection of materials need to fully consider its impact on the deformation characteristics of bent parts.

In short, the deformation characteristics of stamping and bending parts is an important factor affecting product quality, performance and appearance. In actual production, we need to fully consider a variety of factors, precise control of the bending angle, bending radius, springback and other parameters to ensure that the quality of the bent parts to meet the expected requirements. At the same time, the selection of suitable materials and processing methods is also the key to ensure the quality of bent parts. Through in-depth understanding of the deformation characteristics of stamping and bending parts, we can better master this process and provide high-quality metal parts for various industries.

First of all, we need to understand what is a bent part. A bent part is a part that bends a metal material into a certain angle and shape through stamping processing. Such parts are widely used in many industries, such as automotive, aviation, home appliances and so on. The deformation characteristics of bent parts mainly include the following aspects:

1. Bending angle: the bending angle of a bent part refers to the angle at which the metal material is bent during the stamping process. The size of this angle directly affects the shape and size of the bent part. In actual production, the control of the bending angle needs to be very precise to ensure the quality and performance of the product.

2. Bending radius: The bending radius is the radius of the inner arc of the bent part of the bent part. The size of this radius affects the strength and stiffness of the bent part. Generally speaking, the smaller the bending radius, the higher the strength and stiffness of the bent part, but it will also increase the stress concentration of the material, which can easily lead to cracks.

3. Rebound: In the stamping process, the metal material will undergo elastic deformation. When the external force disappears, the material will try to restore the original shape, this phenomenon is called rebound. Rebound phenomenon will affect the precision and stability of the bent parts, so it needs to be controlled in the production process.

4. Material thickness: the material thickness of the bent part will also affect its deformation characteristics. In general, the greater the thickness of the material, the higher the strength and stiffness of the bent parts, but also reduces the plasticity of the material, increasing the processing difficulty. Therefore, the choice of material needs to be weighed according to the actual needs.

5. Material type: different types of metal materials have different mechanical properties and plasticity, which will also affect the deformation characteristics of the bent parts. For example, the plasticity of stainless steel material is poor, easy to produce cracks; while the plasticity of aluminum material is better, but lower strength. Therefore, in the selection of materials need to fully consider its impact on the deformation characteristics of bent parts.

In short, the deformation characteristics of stamping and bending parts is an important factor affecting product quality, performance and appearance. In actual production, we need to fully consider a variety of factors, precise control of the bending angle, bending radius, springback and other parameters to ensure that the quality of the bent parts to meet the expected requirements. At the same time, the selection of suitable materials and processing methods is also the key to ensure the quality of bent parts. Through in-depth understanding of the deformation characteristics of stamping and bending parts, we can better master this process and provide high-quality metal parts for various industries.