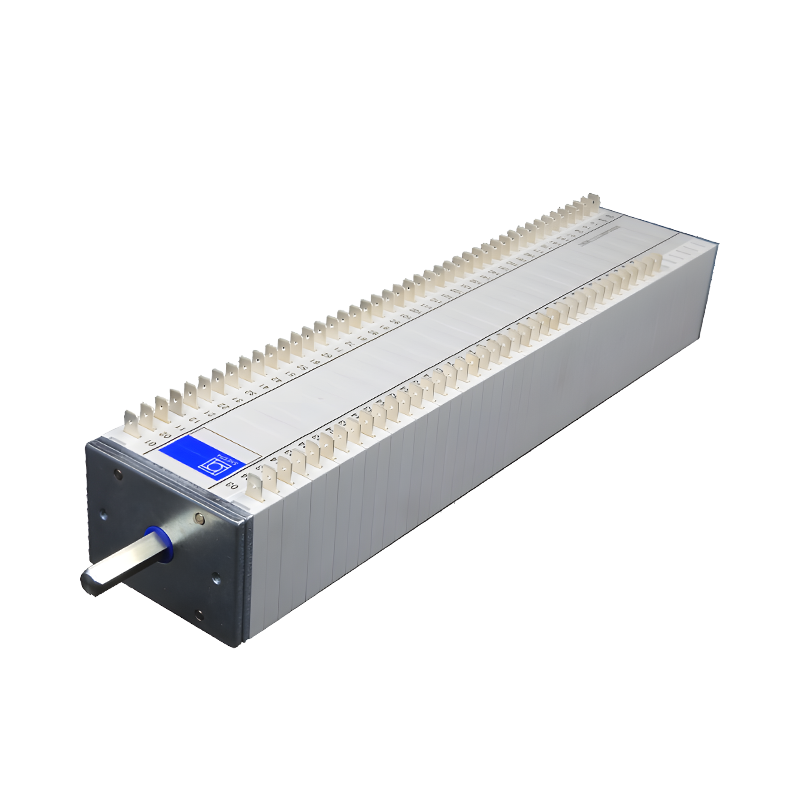

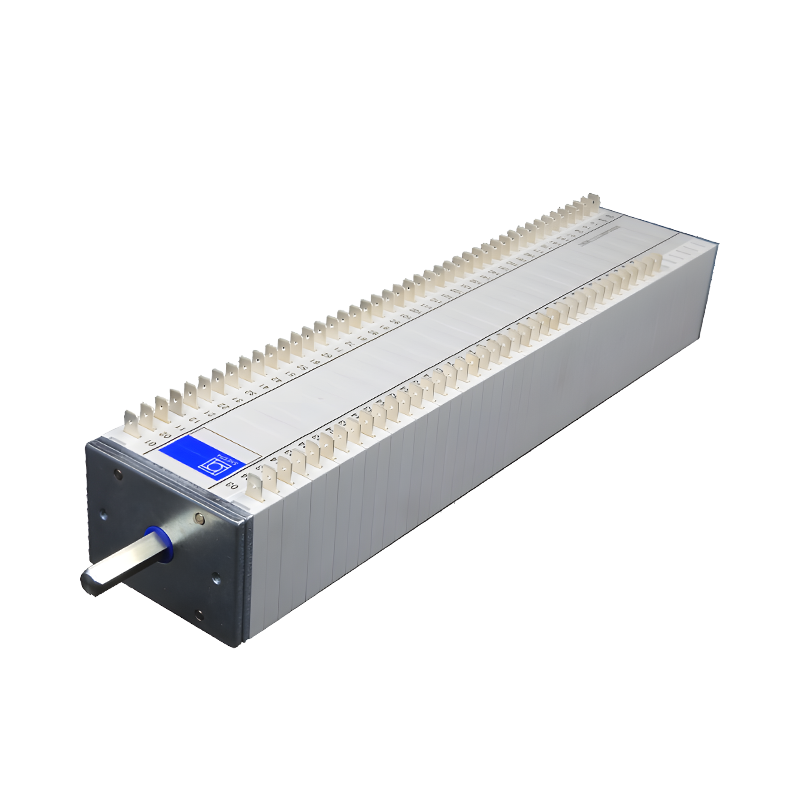

Auxiliary switches crimp-on and plug-in: technical details and application differences

Release time:2024-06-04

Auxiliary switches play an indispensable role in the sophisticated world of power systems. They act as miniature guards in the circuit, ensuring the safe flow and distribution of current. Among the many designs of auxiliary switches, the crimp and plug-in types are two common connection methods, each with its own characteristics and suitable for different application scenarios. In this article, we will discuss in depth the differences between these two connection methods and their performance in practical applications.

Crimp-type auxiliary switches, as the name suggests, are a way of connecting wires and switches together through pressure. The advantages of this type of connection are its stability and reliability. Once the crimping is complete, the connection is virtually impervious to loosening due to vibration or temperature changes, which is critical for power systems that require stable operation over long periods of time. In addition, crimped connections often do not require welding or other complex processes, which simplifies the installation process somewhat and reduces maintenance costs.

However, crimped connections also have their limitations. Due to their fixed nature, it is relatively difficult to adjust or replace wires once the installation is complete. This means that precise calculations and planning are required at the design stage to avoid large-scale changes at a later stage. In addition, crimped connections require a high level of operator skill, and improper crimping may result in poor contact and affect the performance of the entire system.

In contrast, plug-in auxiliary switches offer more flexibility. With a simple plugging and unplugging action, users can quickly connect or disconnect wires, which makes repairs and upgrades easier. Plug-in connections are often standardized, allowing switches of different makes and models to be interchangeable, providing users with more options.

However, the disadvantages of plug-in connections should not be overlooked. Frequent plugging and unplugging may lead to wear and tear of the contact points, thus affecting the reliability of the connection. In high vibration or high temperature environments, plug-in connections may fail due to poor contact. Therefore, while plug-in connections offer convenience in everyday use, their performance may not be as stable as crimp connections in extreme or specialized environments.

When choosing between crimp or plug-in auxiliary switches, engineers and technicians need to consider the application environment, maintenance needs and cost-effectiveness. For example, in systems that require frequent maintenance or upgrades, plug-in may be a more appropriate choice, while crimp-on may be preferable in applications that require the ultimate in stability and reliability.

In short, whether they are crimp or plug-in auxiliary switches, they are an important part of the power system. Understanding their characteristics and application scenarios can help us make more informed choices to ensure the efficient and safe operation of power systems. As technology continues to advance, we expect more innovative connections to emerge in the future to meet the growing demand for power.

Crimp-type auxiliary switches, as the name suggests, are a way of connecting wires and switches together through pressure. The advantages of this type of connection are its stability and reliability. Once the crimping is complete, the connection is virtually impervious to loosening due to vibration or temperature changes, which is critical for power systems that require stable operation over long periods of time. In addition, crimped connections often do not require welding or other complex processes, which simplifies the installation process somewhat and reduces maintenance costs.

However, crimped connections also have their limitations. Due to their fixed nature, it is relatively difficult to adjust or replace wires once the installation is complete. This means that precise calculations and planning are required at the design stage to avoid large-scale changes at a later stage. In addition, crimped connections require a high level of operator skill, and improper crimping may result in poor contact and affect the performance of the entire system.

In contrast, plug-in auxiliary switches offer more flexibility. With a simple plugging and unplugging action, users can quickly connect or disconnect wires, which makes repairs and upgrades easier. Plug-in connections are often standardized, allowing switches of different makes and models to be interchangeable, providing users with more options.

However, the disadvantages of plug-in connections should not be overlooked. Frequent plugging and unplugging may lead to wear and tear of the contact points, thus affecting the reliability of the connection. In high vibration or high temperature environments, plug-in connections may fail due to poor contact. Therefore, while plug-in connections offer convenience in everyday use, their performance may not be as stable as crimp connections in extreme or specialized environments.

When choosing between crimp or plug-in auxiliary switches, engineers and technicians need to consider the application environment, maintenance needs and cost-effectiveness. For example, in systems that require frequent maintenance or upgrades, plug-in may be a more appropriate choice, while crimp-on may be preferable in applications that require the ultimate in stability and reliability.

In short, whether they are crimp or plug-in auxiliary switches, they are an important part of the power system. Understanding their characteristics and application scenarios can help us make more informed choices to ensure the efficient and safe operation of power systems. As technology continues to advance, we expect more innovative connections to emerge in the future to meet the growing demand for power.