Addressing the Challenges of Deformation in Injection Molding Processing of Medical Plastic Parts

Release time:2024-06-03

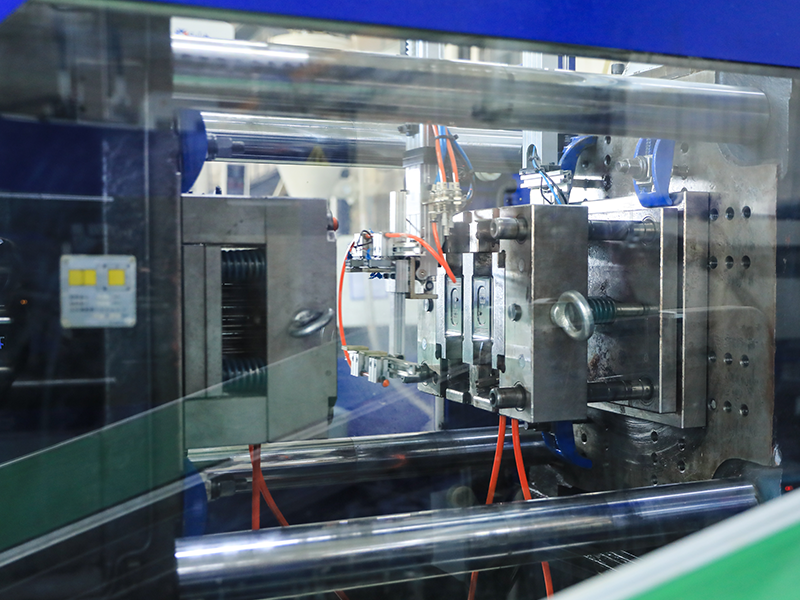

Injection molding processing of plastic parts is a crucial technology in the medical industry. However, due to various reasons, these plastic parts may suffer from deformation during processing. This not only affects the quality and performance of the product, but may also pose a threat to the health and safety of patients. Therefore, we must find effective solutions to meet this challenge.

First of all, we need to understand the causes of deformation in injection molding processing of medical plastic parts. This may be due to irrational mold design, improper material selection, incorrect processing process parameter settings, or insufficient operator skill level. Only with a deep understanding of the root causes of these problems, we can make targeted improvements.

Secondly, we need to optimize the mold design. A reasonable mold design should be able to ensure that the plastic parts in the injection molding process of uniform filling and cooling, so as to avoid the occurrence of deformation. We can use computer-aided design (CAD) technology to accurately simulate and analyze the structure and performance of the mold so that potential problems can be identified and solved before manufacturing.

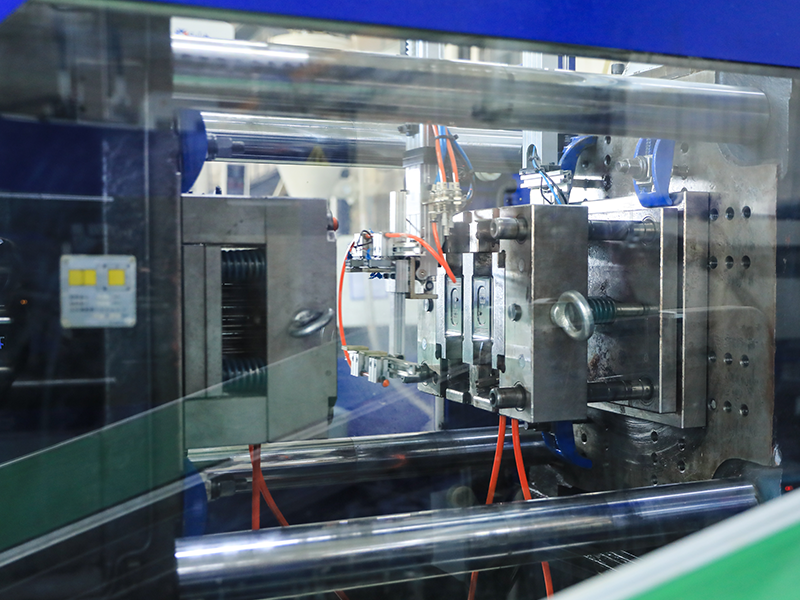

Next, we need to select the right material. Different plastic materials have different physical and chemical properties, which may affect their behavior during the injection molding process. We should choose those materials with good fluidity, stability and compatibility to minimize the risk of deformation according to the requirements and characteristics of the product.

In addition, we need to adjust the processing parameters. Changes in temperature, pressure, speed and other parameters may affect the shape and size of plastic parts. We should find the best combination of process parameters through experiments and data analysis to ensure the quality of plastic parts.

Finally, we need to improve the technical level of operators. They should receive professional training and guidance to master the correct operation methods and techniques. At the same time, they should also have good observation and judgment ability, and be able to find and solve any problems that may lead to the deformation of plastic parts in time during the production process.

Overall, solving the problem of deformation of medical plastic parts injection molding processing requires us to make efforts from several aspects. By optimizing the mold design, choosing the right materials, adjusting the process parameters and improving the technical level of the operators, we can effectively reduce the occurrence of this problem and thus improve the quality and safety of the products.

First of all, we need to understand the causes of deformation in injection molding processing of medical plastic parts. This may be due to irrational mold design, improper material selection, incorrect processing process parameter settings, or insufficient operator skill level. Only with a deep understanding of the root causes of these problems, we can make targeted improvements.

Secondly, we need to optimize the mold design. A reasonable mold design should be able to ensure that the plastic parts in the injection molding process of uniform filling and cooling, so as to avoid the occurrence of deformation. We can use computer-aided design (CAD) technology to accurately simulate and analyze the structure and performance of the mold so that potential problems can be identified and solved before manufacturing.

Next, we need to select the right material. Different plastic materials have different physical and chemical properties, which may affect their behavior during the injection molding process. We should choose those materials with good fluidity, stability and compatibility to minimize the risk of deformation according to the requirements and characteristics of the product.

In addition, we need to adjust the processing parameters. Changes in temperature, pressure, speed and other parameters may affect the shape and size of plastic parts. We should find the best combination of process parameters through experiments and data analysis to ensure the quality of plastic parts.

Finally, we need to improve the technical level of operators. They should receive professional training and guidance to master the correct operation methods and techniques. At the same time, they should also have good observation and judgment ability, and be able to find and solve any problems that may lead to the deformation of plastic parts in time during the production process.

Overall, solving the problem of deformation of medical plastic parts injection molding processing requires us to make efforts from several aspects. By optimizing the mold design, choosing the right materials, adjusting the process parameters and improving the technical level of the operators, we can effectively reduce the occurrence of this problem and thus improve the quality and safety of the products.