Causes of Scuffing in Stamping Processed Bent Parts

Release time:2024-05-29

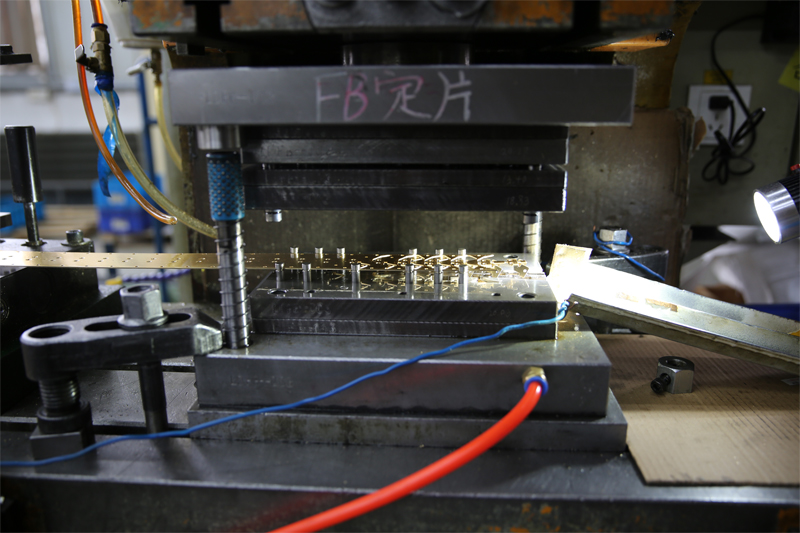

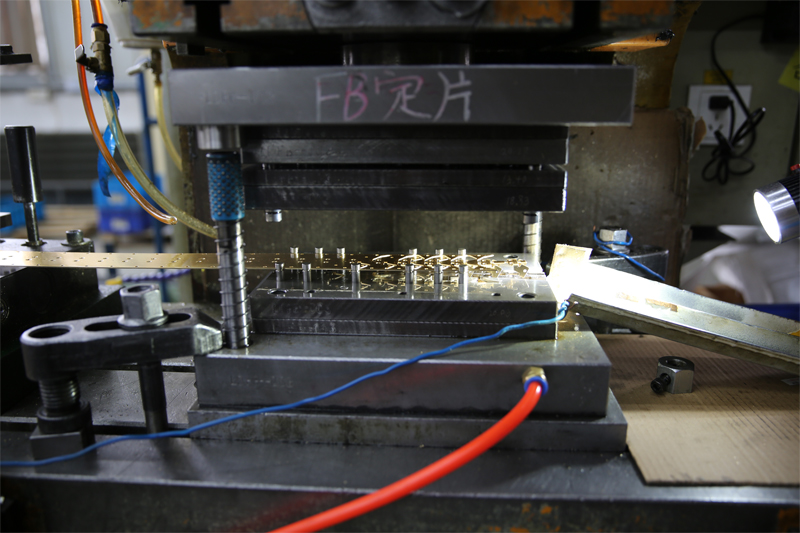

Stamping is a common metal forming process in the manufacturing industry, which involves plastic deformation of sheet metal by applying pressure to obtain the desired shape and size. However, the problem of scuffing of bent parts occurs from time to time during the stamping process, which not only affects the appearance quality of the product, but also may lead to the functional failure of the part. In this paper, we will discuss the causes of scuffing of bent parts in stamping process and propose corresponding solution measures.

First of all, the unreasonable design of the mold is one of the main reasons for the bruising of bent parts. The mold is the core part of stamping processing, and the reasonableness of its design directly affects the product quality. If the radius of the round corner of the mold is too small, the gap of the mold is not uniform or the surface roughness of the mold is not enough, it may lead to abrasion of the bent parts in the stamping process. Therefore, these factors should be fully considered when designing the mold to ensure the rationality and accuracy of the mold.

Secondly, improper selection of materials is also an important cause of abrasion of bent parts. Different metal materials have different hardness, toughness and ductility, and the selection of suitable materials is essential to ensure the quality of stamping processing. If the hardness of the selected material is too high, it is easy to lead to cracks in the stamping process of the bent parts; and if the selected material hardness is too low, there may be serious abrasion phenomenon in the stamping process. Therefore, in the selection of materials, should be based on the specific needs of the product and processing technology requirements for a reasonable choice.

Again, improper setting of stamping process parameters can also lead to bruising of bent parts. Stamping speed, pressure and temperature and other process parameters have an important impact on the stamping process. If the stamping speed is too fast, it may lead to bending parts in the stamping process to produce intense friction, thus triggering abrasions; and if the stamping pressure is too large or too small, it may also lead to bending parts in the stamping process abrasions. Therefore, when setting the stamping process parameters, it should be reasonably adjusted according to the specific production conditions and product requirements.

Finally, the technical level and experience of the operator is also an important factor affecting the scuffing of bent parts. Operators need to have rich stamping processing experience and skillful skills to ensure the stability of the stamping process and product quality. If the operator lacks experience or skills, it may lead to misoperation in the stamping process, which may lead to scratches on the bent parts. Therefore, improving the technical level and training experience of operators is an effective way to reduce the scuffing of bent parts.

In summary, the reasons for the abrasion of bent parts in stamping processing mainly include unreasonable mold design, improper material selection, improper setting of stamping process parameters and insufficient technical level and experience of operators. To solve this problem, we need to start from the mold design, material selection, process parameter settings and operator training and other aspects, to take comprehensive measures to improve the quality of stamping processing, to ensure that the surface quality of the bent parts and functional performance. Only in this way, we can be invincible in the fierce market competition, and make greater contributions to the development of the manufacturing industry.

Translated with DeepL.com (free version)

First of all, the unreasonable design of the mold is one of the main reasons for the bruising of bent parts. The mold is the core part of stamping processing, and the reasonableness of its design directly affects the product quality. If the radius of the round corner of the mold is too small, the gap of the mold is not uniform or the surface roughness of the mold is not enough, it may lead to abrasion of the bent parts in the stamping process. Therefore, these factors should be fully considered when designing the mold to ensure the rationality and accuracy of the mold.

Secondly, improper selection of materials is also an important cause of abrasion of bent parts. Different metal materials have different hardness, toughness and ductility, and the selection of suitable materials is essential to ensure the quality of stamping processing. If the hardness of the selected material is too high, it is easy to lead to cracks in the stamping process of the bent parts; and if the selected material hardness is too low, there may be serious abrasion phenomenon in the stamping process. Therefore, in the selection of materials, should be based on the specific needs of the product and processing technology requirements for a reasonable choice.

Again, improper setting of stamping process parameters can also lead to bruising of bent parts. Stamping speed, pressure and temperature and other process parameters have an important impact on the stamping process. If the stamping speed is too fast, it may lead to bending parts in the stamping process to produce intense friction, thus triggering abrasions; and if the stamping pressure is too large or too small, it may also lead to bending parts in the stamping process abrasions. Therefore, when setting the stamping process parameters, it should be reasonably adjusted according to the specific production conditions and product requirements.

Finally, the technical level and experience of the operator is also an important factor affecting the scuffing of bent parts. Operators need to have rich stamping processing experience and skillful skills to ensure the stability of the stamping process and product quality. If the operator lacks experience or skills, it may lead to misoperation in the stamping process, which may lead to scratches on the bent parts. Therefore, improving the technical level and training experience of operators is an effective way to reduce the scuffing of bent parts.

In summary, the reasons for the abrasion of bent parts in stamping processing mainly include unreasonable mold design, improper material selection, improper setting of stamping process parameters and insufficient technical level and experience of operators. To solve this problem, we need to start from the mold design, material selection, process parameter settings and operator training and other aspects, to take comprehensive measures to improve the quality of stamping processing, to ensure that the surface quality of the bent parts and functional performance. Only in this way, we can be invincible in the fierce market competition, and make greater contributions to the development of the manufacturing industry.

Translated with DeepL.com (free version)