Precautions for Aluminum Stamping Processing

Release time:2024-05-27

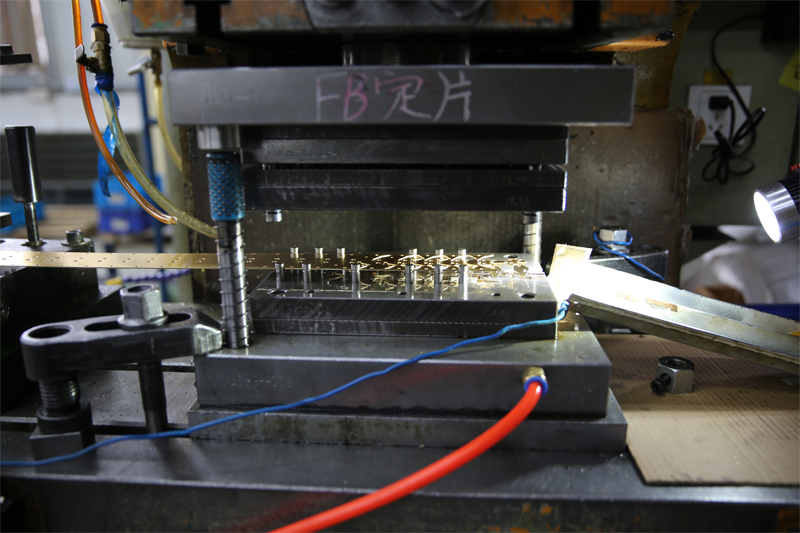

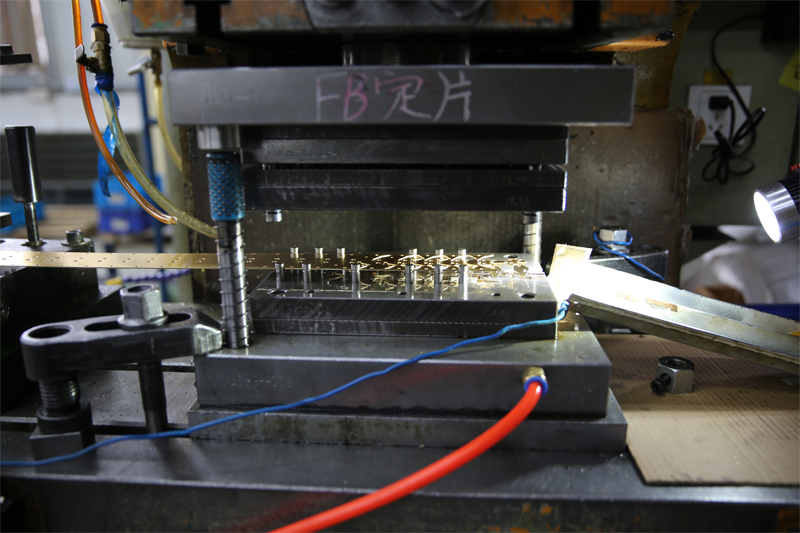

In the world of aluminum stamping, every detail is crucial. Not only because of the nature of aluminum, but also because of the pursuit of precision and quality that lies behind it. Today, let's take a step into this field of challenges and opportunities, and explore the considerations that must be kept in mind during the aluminum stamping process.

First, we must recognize the special characteristics of aluminum itself. Compared to other metals, aluminum has higher ductility, which means it is more prone to deformation during the stamping process. Therefore, choosing the right stamping oil is especially important. Quality stamping oil not only reduces frictional resistance and heat generation, but also effectively protects the die and aluminum, extending its service life.

Secondly, the selection of molds should not be neglected. As aluminum is soft and easy to stick to the mold, so in the selection of mold materials, should give priority to high hardness, wear resistance material. At the same time, the design of the mold should be as simple as possible, avoiding overly complex shapes, in order to reduce the stress concentration in the stamping process.

In addition, the control of stamping speed is also critical. Too fast a speed may lead to localized overheating of the aluminum, affecting its mechanical properties; while too slow a speed will reduce production efficiency. Therefore, finding a balance between ensuring product quality and improving production efficiency is a challenge that every stamping engineer needs to face.

Of course, we can't ignore the processing work after stamping. After aluminum stamping parts are processed, some stamping oil or other impurities often remain on the surface. These residues will not only affect the appearance quality of the product, but also may become a hidden danger of corrosion. Therefore, timely and thorough cleaning is particularly important. At the same time, for some products with special requirements, anodizing, spraying and other post-treatment processes can also be carried out to further enhance their performance and aesthetics.

In this process, we not only need the support of technology, but also need a heart for the relentless pursuit of perfection. Every stamping is a challenge to the process; every finished product is a test of quality. Only when we really put our heart into every detail, can we walk farther and more steadily on the road of aluminum stamping and processing.

Finally, I would like to say that aluminum stamping processing is not an overnight process. It needs us to keep learning, keep trying and keep summarizing experience. Only in this way can we gain a foothold in this industry full of changes and create more amazing products.

So, let's carry the love and reverence for technology and keep moving forward on the road of aluminum stamping processing together!

First, we must recognize the special characteristics of aluminum itself. Compared to other metals, aluminum has higher ductility, which means it is more prone to deformation during the stamping process. Therefore, choosing the right stamping oil is especially important. Quality stamping oil not only reduces frictional resistance and heat generation, but also effectively protects the die and aluminum, extending its service life.

Secondly, the selection of molds should not be neglected. As aluminum is soft and easy to stick to the mold, so in the selection of mold materials, should give priority to high hardness, wear resistance material. At the same time, the design of the mold should be as simple as possible, avoiding overly complex shapes, in order to reduce the stress concentration in the stamping process.

In addition, the control of stamping speed is also critical. Too fast a speed may lead to localized overheating of the aluminum, affecting its mechanical properties; while too slow a speed will reduce production efficiency. Therefore, finding a balance between ensuring product quality and improving production efficiency is a challenge that every stamping engineer needs to face.

Of course, we can't ignore the processing work after stamping. After aluminum stamping parts are processed, some stamping oil or other impurities often remain on the surface. These residues will not only affect the appearance quality of the product, but also may become a hidden danger of corrosion. Therefore, timely and thorough cleaning is particularly important. At the same time, for some products with special requirements, anodizing, spraying and other post-treatment processes can also be carried out to further enhance their performance and aesthetics.

In this process, we not only need the support of technology, but also need a heart for the relentless pursuit of perfection. Every stamping is a challenge to the process; every finished product is a test of quality. Only when we really put our heart into every detail, can we walk farther and more steadily on the road of aluminum stamping and processing.

Finally, I would like to say that aluminum stamping processing is not an overnight process. It needs us to keep learning, keep trying and keep summarizing experience. Only in this way can we gain a foothold in this industry full of changes and create more amazing products.

So, let's carry the love and reverence for technology and keep moving forward on the road of aluminum stamping processing together!