The pulse of power, guarded by crimp-type auxiliary switches

Release time:2024-05-23

In the heart of modern industry, electrical equipment is like life blood, constantly delivering energy. In this huge and complex power network, there is a seemingly insignificant but vital component - the crimp connection of the auxiliary switch. Although it is small, it is the guardian of the safe and stable operation of high-voltage power equipment.

Imagine, when the night falls, the city lights, behind the lights, is a myriad of power equipment in the silent work. In these devices, high-voltage current as the rushing river, powerful and untamable. Without precise and reliable control, this force can go out of control at any time, resulting in catastrophic consequences. The crimp connection of the auxiliary switch is the key to precisely directing and controlling this force.

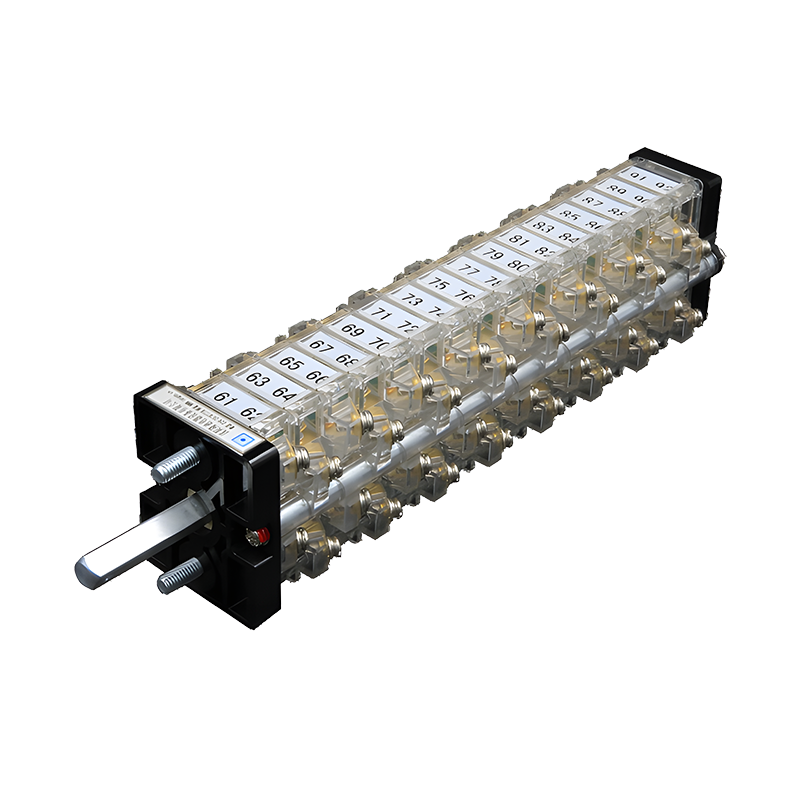

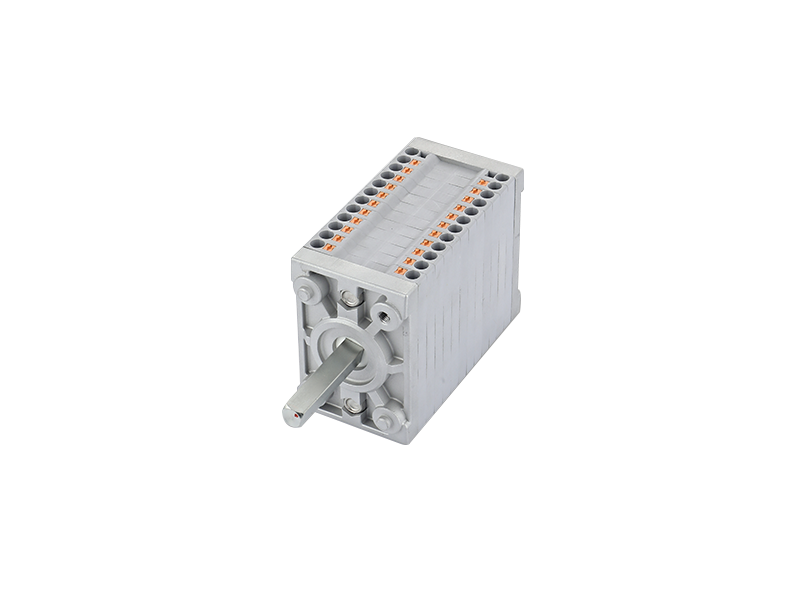

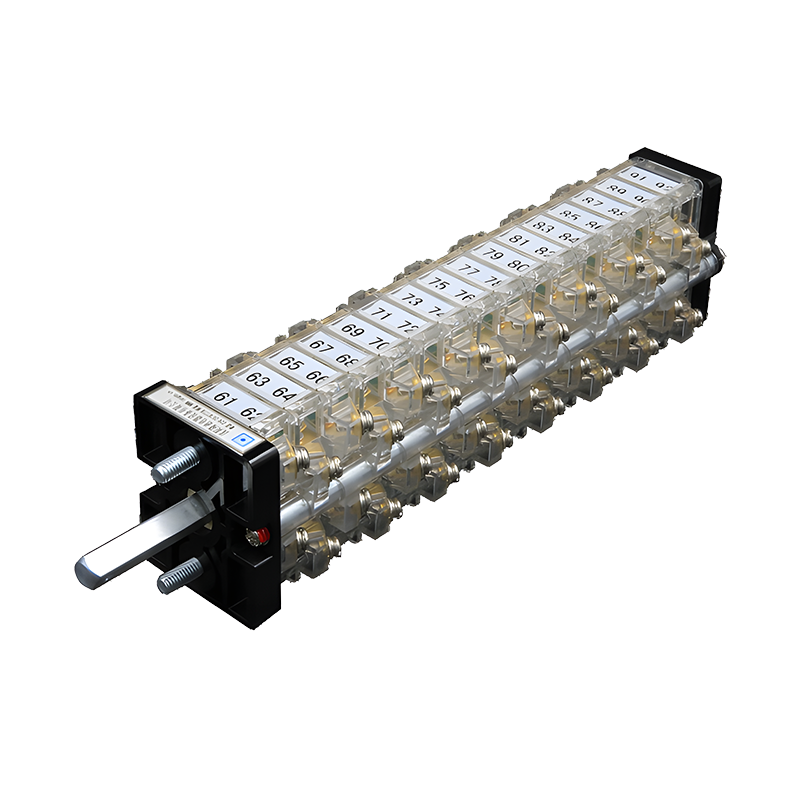

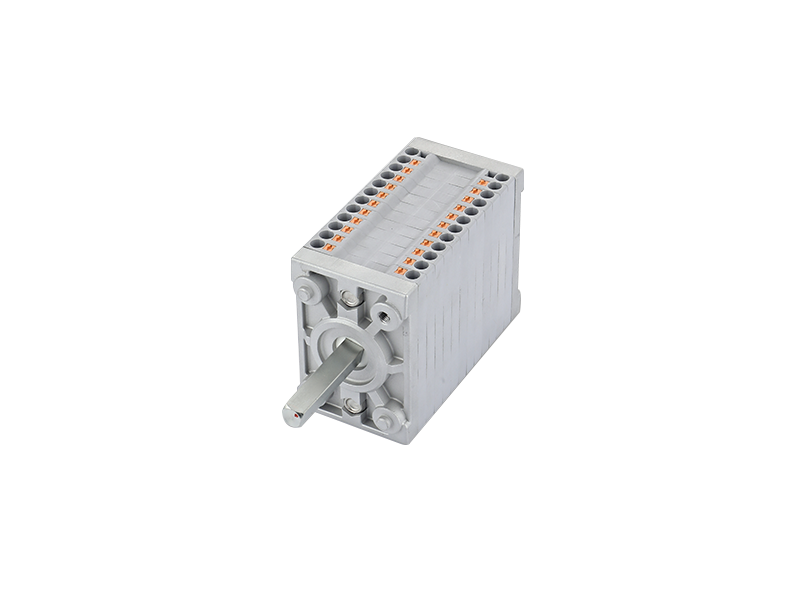

The crimped auxiliary switch, with its unique design and materials, ensures reliability and safety in high voltage environments. It works by physically crimping electrically conductive materials together securely to provide a stable and long-lasting electrical connection. This type of connection not only withstands extreme electrical loads, but also resists the erosion of external environmental factors such as thermal expansion and contraction, humidity, and corrosion.

In high-voltage power equipment, crimp connections for auxiliary switches are used in a variety of applications. For example, they are widely used in high-voltage switchgear, busbar connections in substations, cable joints, and critical parts such as circuit breakers. The stability of these devices is directly related to the safe operation of the entire power grid, so the importance of the crimp connection of auxiliary switches is self-evident.

For example, the high-voltage switchgear is the “commander” of the grid and is responsible for switching off or on the circuit when necessary. If the connection is not strong, it may lead to switch failure, short circuit or even explosion, which brings great threat to people's life and property safety. The crimp-type auxiliary switch is like the commander's right-hand man, to ensure that the command is carried out accurately.

When designing and manufacturing crimp-type auxiliary switches, engineers take into account extreme conditions to ensure that they work in the harshest environments. These switches are typically made of corrosion-resistant metals, precision machined and rigorously tested to ensure they perform to the highest standards.

However, despite the importance of the crimped connections of auxiliary switches, they are often overlooked. They are a tiny part of the grand scheme of power equipment, but it is these tiny parts that form the impenetrable defense of the power system.

As technology advances, the crimp connection of auxiliary switches is constantly evolving and innovating. The use of new materials, more precise manufacturing processes, and smarter monitoring systems continue to enhance the performance of these connections to meet the growing demand for power.

In the future, with the spread of renewable energies and the development of smart grids, crimp connections for auxiliary switches will continue to play a vital role. They are not only the guardians of power transmission, but also the witnesses of our modern civilization.

So, the next time we turn on the lights and enjoy the convenience of electricity, think about the auxiliary switches' crimp connections that work silently behind the scenes. Although they are inconspicuous, they are powerful cornerstones that support our daily lives. In this era of electricity, they are the real heroes, guarding the city's light and safeguarding our safety.

Translated with DeepL.com (free version)

Imagine, when the night falls, the city lights, behind the lights, is a myriad of power equipment in the silent work. In these devices, high-voltage current as the rushing river, powerful and untamable. Without precise and reliable control, this force can go out of control at any time, resulting in catastrophic consequences. The crimp connection of the auxiliary switch is the key to precisely directing and controlling this force.

The crimped auxiliary switch, with its unique design and materials, ensures reliability and safety in high voltage environments. It works by physically crimping electrically conductive materials together securely to provide a stable and long-lasting electrical connection. This type of connection not only withstands extreme electrical loads, but also resists the erosion of external environmental factors such as thermal expansion and contraction, humidity, and corrosion.

In high-voltage power equipment, crimp connections for auxiliary switches are used in a variety of applications. For example, they are widely used in high-voltage switchgear, busbar connections in substations, cable joints, and critical parts such as circuit breakers. The stability of these devices is directly related to the safe operation of the entire power grid, so the importance of the crimp connection of auxiliary switches is self-evident.

For example, the high-voltage switchgear is the “commander” of the grid and is responsible for switching off or on the circuit when necessary. If the connection is not strong, it may lead to switch failure, short circuit or even explosion, which brings great threat to people's life and property safety. The crimp-type auxiliary switch is like the commander's right-hand man, to ensure that the command is carried out accurately.

When designing and manufacturing crimp-type auxiliary switches, engineers take into account extreme conditions to ensure that they work in the harshest environments. These switches are typically made of corrosion-resistant metals, precision machined and rigorously tested to ensure they perform to the highest standards.

However, despite the importance of the crimped connections of auxiliary switches, they are often overlooked. They are a tiny part of the grand scheme of power equipment, but it is these tiny parts that form the impenetrable defense of the power system.

As technology advances, the crimp connection of auxiliary switches is constantly evolving and innovating. The use of new materials, more precise manufacturing processes, and smarter monitoring systems continue to enhance the performance of these connections to meet the growing demand for power.

In the future, with the spread of renewable energies and the development of smart grids, crimp connections for auxiliary switches will continue to play a vital role. They are not only the guardians of power transmission, but also the witnesses of our modern civilization.

So, the next time we turn on the lights and enjoy the convenience of electricity, think about the auxiliary switches' crimp connections that work silently behind the scenes. Although they are inconspicuous, they are powerful cornerstones that support our daily lives. In this era of electricity, they are the real heroes, guarding the city's light and safeguarding our safety.

Translated with DeepL.com (free version)