What is the power source of medical device shell injection molding processing to launch the mechanism?

Release time:2024-04-02

In

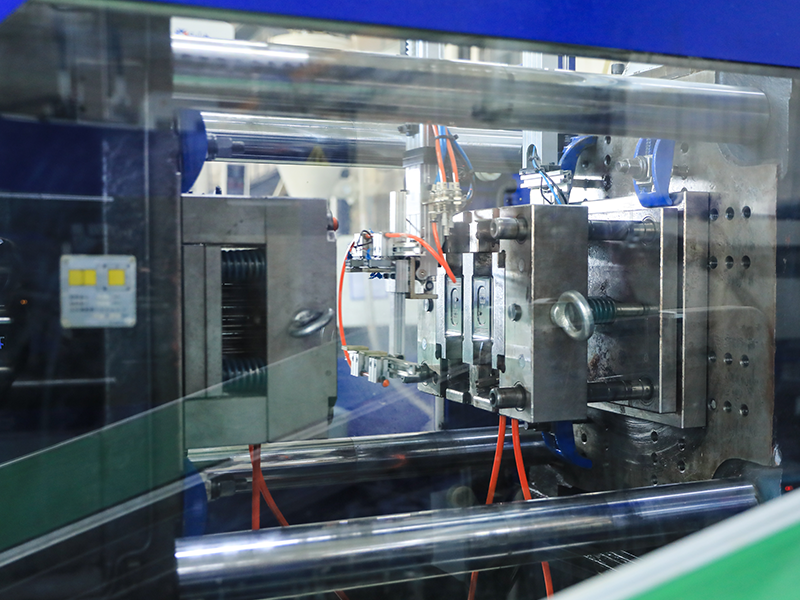

the modern medical field, the manufacturing of medical devices is a

precise and complex process, in which the shell injection molding

processing is a key step to ensure the safe, stable and efficient

operation of medical devices. In this process, the power source of the

push-out mechanism plays a crucial role. It is not only the embodiment

of physical force, but also the crystallization of technological

innovation and human wisdom.

Power source, as the name suggests, is to promote the medical device shell injection molding processing push the fundamental power of the operation of the mechanism. This power source can be various, including hydraulic drive, motor drive, pneumatic or mechanical drive. Each power source has its own unique advantages and application scenarios, and together they form a solid cornerstone of medical device manufacturing.

Hydraulic drive systems are known for their stability and powerful thrust, providing continuous and uniform force during the injection molding process to ensure the quality and precision of molded medical device housings. This power source is particularly suitable for applications where precision is critical, such as the manufacture of pacemakers or neurostimulator housings.

Motor-driven systems are favored for their high efficiency and energy-saving properties. With fine electronic control, the motors can be precisely adjusted in terms of push-out speed and force, adapting to complex and variable machining requirements. This power source is suitable for high-volume production, such as the manufacture of shells for disposable syringes or infusion tubes.

Pneumatic drive systems are highly regarded for their fast response and cleanliness. Pneumatic pressure is used as a power transfer medium for fast motion execution and a contamination-free operating environment. This power source is suitable for the production of housings for medical devices that require high levels of hygiene, such as surgical tools or labware.

Mechanical drive systems, on the other hand, rely on precision gears and transmissions for their reliability and durability. While mechanical drives may not be as fast or flexible as other power sources, they offer unrivaled stability and long-term performance guarantees in heavy-duty and high-stress applications.

Regardless of the power source, they are an integral part of the injection molding process for medical device housings. They exist not only to enable physical propulsion, but also to ensure the safety, reliability and efficiency of medical devices. Behind every precision medical device, there is a powerful power source silently supporting, they are the guardian of medical innovation, is the guardian of human health.

Therefore, when we talk about the power source of the medical device housing injection molding processing launching mechanism, we are not only discussing a technology or a device, we are also discussing an important topic of life and health. Every advancement of these power sources is a contribution to human well-being, and every innovation is a tribute to the dignity of life.

In the future, with the continuous progress of science and technology, the power sources of medical device housing injection molding processing will be more intelligent, precise and environmentally friendly. They will continue to play an irreplaceable role in the medical field, contributing to human health and bringing hope and light to the world.

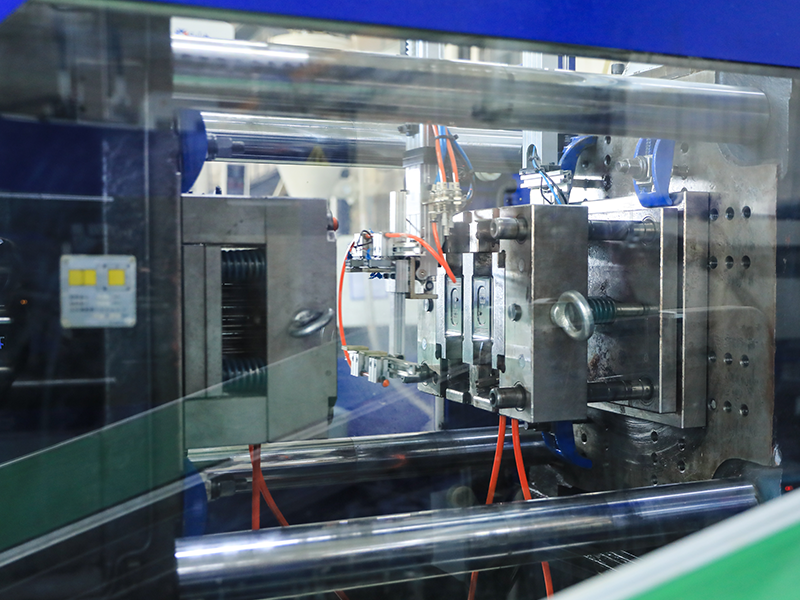

Power source, as the name suggests, is to promote the medical device shell injection molding processing push the fundamental power of the operation of the mechanism. This power source can be various, including hydraulic drive, motor drive, pneumatic or mechanical drive. Each power source has its own unique advantages and application scenarios, and together they form a solid cornerstone of medical device manufacturing.

Hydraulic drive systems are known for their stability and powerful thrust, providing continuous and uniform force during the injection molding process to ensure the quality and precision of molded medical device housings. This power source is particularly suitable for applications where precision is critical, such as the manufacture of pacemakers or neurostimulator housings.

Motor-driven systems are favored for their high efficiency and energy-saving properties. With fine electronic control, the motors can be precisely adjusted in terms of push-out speed and force, adapting to complex and variable machining requirements. This power source is suitable for high-volume production, such as the manufacture of shells for disposable syringes or infusion tubes.

Pneumatic drive systems are highly regarded for their fast response and cleanliness. Pneumatic pressure is used as a power transfer medium for fast motion execution and a contamination-free operating environment. This power source is suitable for the production of housings for medical devices that require high levels of hygiene, such as surgical tools or labware.

Mechanical drive systems, on the other hand, rely on precision gears and transmissions for their reliability and durability. While mechanical drives may not be as fast or flexible as other power sources, they offer unrivaled stability and long-term performance guarantees in heavy-duty and high-stress applications.

Regardless of the power source, they are an integral part of the injection molding process for medical device housings. They exist not only to enable physical propulsion, but also to ensure the safety, reliability and efficiency of medical devices. Behind every precision medical device, there is a powerful power source silently supporting, they are the guardian of medical innovation, is the guardian of human health.

Therefore, when we talk about the power source of the medical device housing injection molding processing launching mechanism, we are not only discussing a technology or a device, we are also discussing an important topic of life and health. Every advancement of these power sources is a contribution to human well-being, and every innovation is a tribute to the dignity of life.

In the future, with the continuous progress of science and technology, the power sources of medical device housing injection molding processing will be more intelligent, precise and environmentally friendly. They will continue to play an irreplaceable role in the medical field, contributing to human health and bringing hope and light to the world.