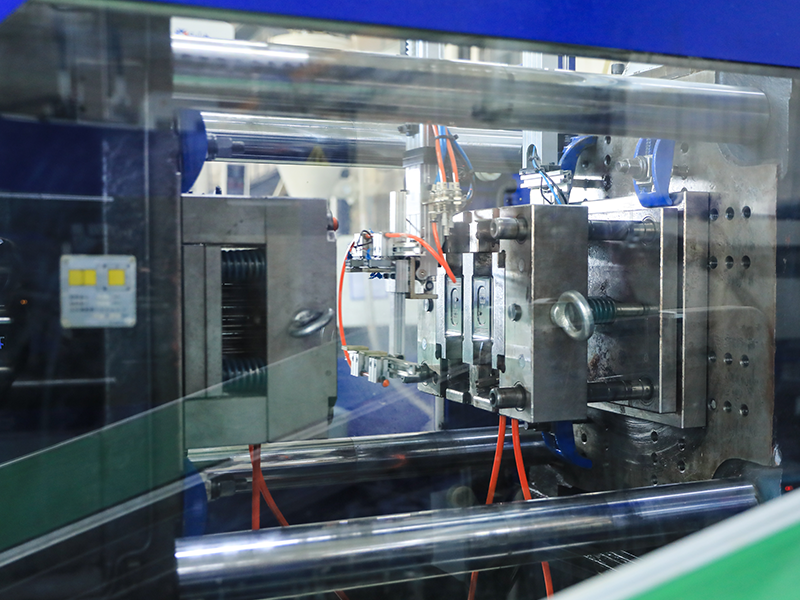

What should I do if there are black spots on the surface of injection molded parts?

Release time:2024-03-19

Black spots are black spots or stripes on the surface of injection molded parts.

Reasons for the formation of black spots on injection molded parts

Injection molding parts processing black spot solution

1. Injection molding machine:

1) Choose the appropriate tonnage of the injection molding machine;

1)Reduce the temperature of barrel and nozzle;

2) Clean all parts of the injection molding process to avoid the black spot injection molded parts that have been produced to be recycled.

Reasons for the formation of black spots on injection molded parts

(1) Plastic overheating decomposition leads to black spots or streaks. Plastic in the closed barrel, screw surface stays too long, will lead to carbonization degradation, so in the injection molding process to produce black spots or stripes;

Injection molding parts processing black spot solution

1. Injection molding machine:

1) Choose the appropriate tonnage of the injection molding machine;

2) Check whether the inner surface of the barrel and the surface of the screw are scratched with accumulated material.

1)Reduce the temperature of barrel and nozzle;

2) Clean all parts of the injection molding process to avoid the black spot injection molded parts that have been produced to be recycled.