What are the factors that affect the bending machine mold?

Release time:2024-03-13

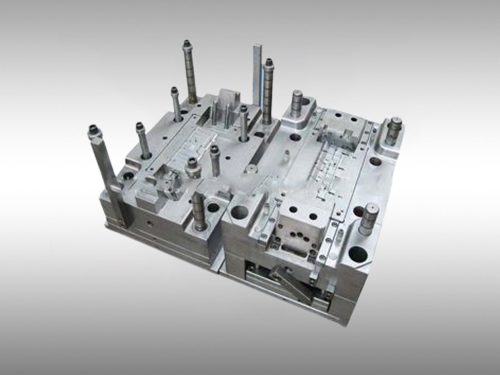

In the vast arena of metalworking, bending machine molds play a key role in determining the precision and quality of the finished product. However, these seemingly indestructible tools are also affected by a variety of factors, which are like invisible hands that quietly shape the performance and life of the mold. Today, let's unveil these influencing factors and explore how they are meticulously woven into a network of influence that determines the fate of the bending machine mold.

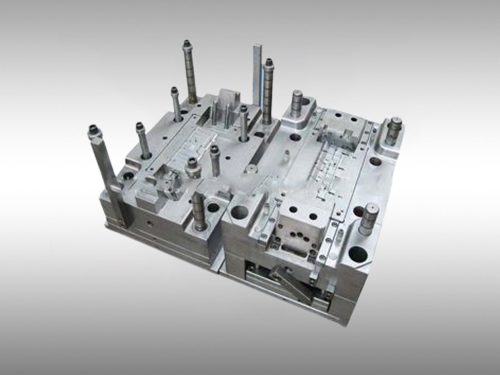

First of all, the choice of material is undoubtedly the primary factor affecting the performance of the mold. High-quality steels, such as those alloys that have undergone special heat treatment, provide better wear resistance and compressive strength. They act as a sturdy shield, protecting the mold from wear and breakage. However, if an inferior material is chosen, the life of the mold will be greatly reduced, like using weak paper to protect against a violent storm, and the results speak for themselves.

Next, the details of the design are also crucial. A well-designed mold ensures that the metal material is evenly stressed during the bending process, reducing the possibility of stress concentrations. The ingenuity of the designer comes into play here, acting like an artist, meticulously sculpting the shape and structure of every inch of the mold to ensure that every bend is precise and accurate. However, design oversights can lead to cracks or deformations in the mold during use, which can be like the undoing of a painting, disrupting the overall harmony and beauty of the piece.

In addition, the way in which the mold is used and maintained also has a profound effect on its life span. Correct operation methods can extend the service life of the mold, while improper use may accelerate its wear and tear. Maintenance should not be ignored, regular inspection and maintenance is like putting a protective film on the molds, so that they can remain in the best condition in the harsh working environment. Neglecting maintenance is like letting a warrior go into battle with his bare hands, which will only accelerate its wear and tear in the end.

Environmental factors should not be ignored either. Extreme temperatures, humidity, and corrosive substances can damage molds. These environmental conditions are like invisible enemies, constantly eroding the health of the mold. Therefore, providing a stable working environment for molds is like building a safe haven for them so that they can perform at their best.

Finally, the precision of the manufacturing process is also crucial in determining the quality of the mold. Precise machining process can ensure that every detail of the mold meets the design requirements, thus ensuring the consistency and reliability of the finished product. Any omission in the process can become a potential defect that affects the performance of the mold, which is like neglecting the stability of a brick in a building, which may eventually lead to the collapse of the entire structure.

With all these factors working together, bending machine molds show their vitality and functionality. They are the unsung heroes of the art of metalworking, quietly supporting the vital cornerstones of our daily lives and industrial development. By understanding and respecting these influences, we can better utilize the potential of our molds to create more perfect and long-lasting metal products.

First of all, the choice of material is undoubtedly the primary factor affecting the performance of the mold. High-quality steels, such as those alloys that have undergone special heat treatment, provide better wear resistance and compressive strength. They act as a sturdy shield, protecting the mold from wear and breakage. However, if an inferior material is chosen, the life of the mold will be greatly reduced, like using weak paper to protect against a violent storm, and the results speak for themselves.

Next, the details of the design are also crucial. A well-designed mold ensures that the metal material is evenly stressed during the bending process, reducing the possibility of stress concentrations. The ingenuity of the designer comes into play here, acting like an artist, meticulously sculpting the shape and structure of every inch of the mold to ensure that every bend is precise and accurate. However, design oversights can lead to cracks or deformations in the mold during use, which can be like the undoing of a painting, disrupting the overall harmony and beauty of the piece.

In addition, the way in which the mold is used and maintained also has a profound effect on its life span. Correct operation methods can extend the service life of the mold, while improper use may accelerate its wear and tear. Maintenance should not be ignored, regular inspection and maintenance is like putting a protective film on the molds, so that they can remain in the best condition in the harsh working environment. Neglecting maintenance is like letting a warrior go into battle with his bare hands, which will only accelerate its wear and tear in the end.

Environmental factors should not be ignored either. Extreme temperatures, humidity, and corrosive substances can damage molds. These environmental conditions are like invisible enemies, constantly eroding the health of the mold. Therefore, providing a stable working environment for molds is like building a safe haven for them so that they can perform at their best.

Finally, the precision of the manufacturing process is also crucial in determining the quality of the mold. Precise machining process can ensure that every detail of the mold meets the design requirements, thus ensuring the consistency and reliability of the finished product. Any omission in the process can become a potential defect that affects the performance of the mold, which is like neglecting the stability of a brick in a building, which may eventually lead to the collapse of the entire structure.

With all these factors working together, bending machine molds show their vitality and functionality. They are the unsung heroes of the art of metalworking, quietly supporting the vital cornerstones of our daily lives and industrial development. By understanding and respecting these influences, we can better utilize the potential of our molds to create more perfect and long-lasting metal products.