The Art and Precision of Medical Injection Molded Parts Processing

Release time:2024-03-05

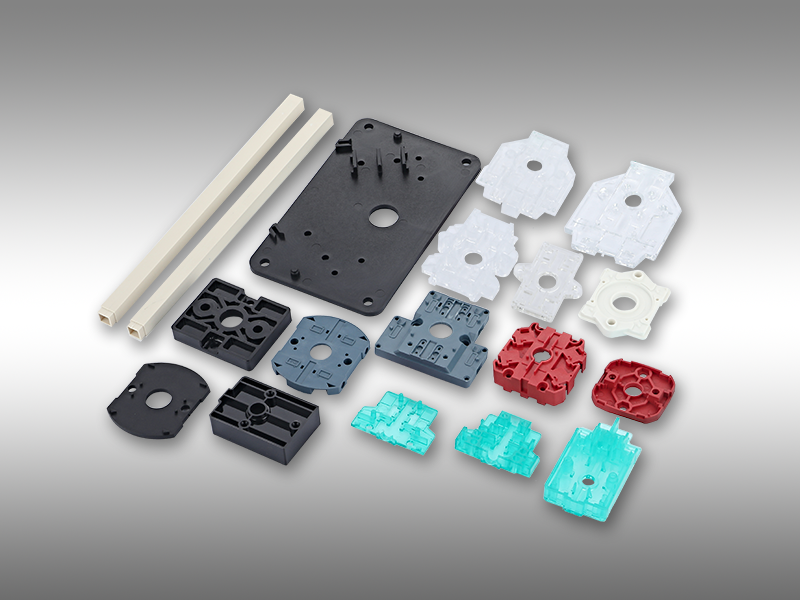

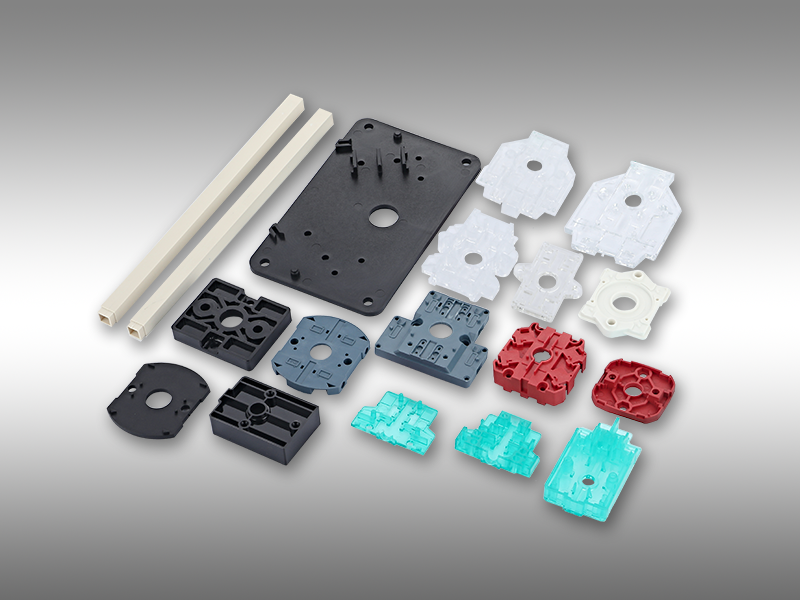

In the medical field, every detail is related to the safety and health of life. As an important part of medical devices, the processing of medical injection molded parts requires not only precise technical support, but also a sense of artistry. In this article, we will discuss the issues that need to be addressed during the processing of medical injection molded parts to ensure that each product meets the highest quality standards.

First, material selection is the foundation of medical injection molded part processing. Medical-grade plastics must meet strict biocompatibility and safety standards. This requires processors to have an in-depth understanding of the material's properties, including temperature resistance, chemical resistance, mechanical strength, and ability to withstand sterilization processes. Choosing the right material is the first step in ensuring product quality and patient safety.

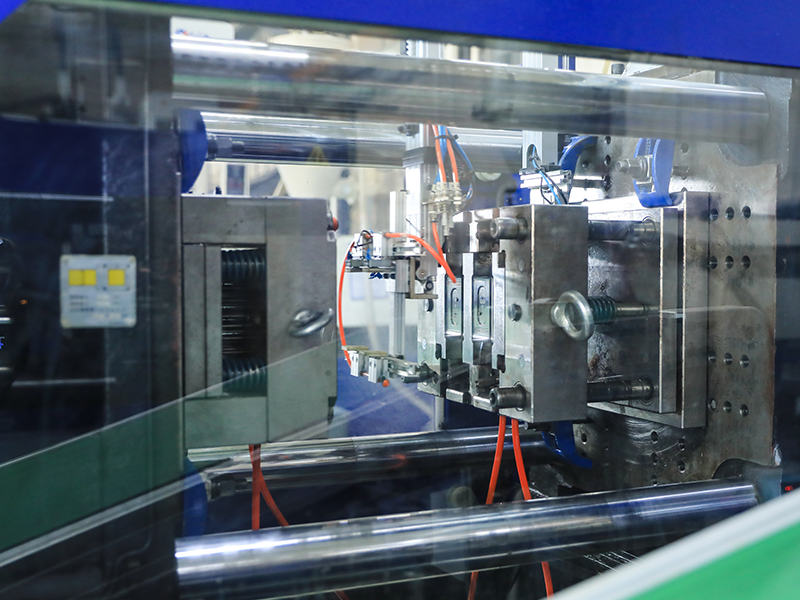

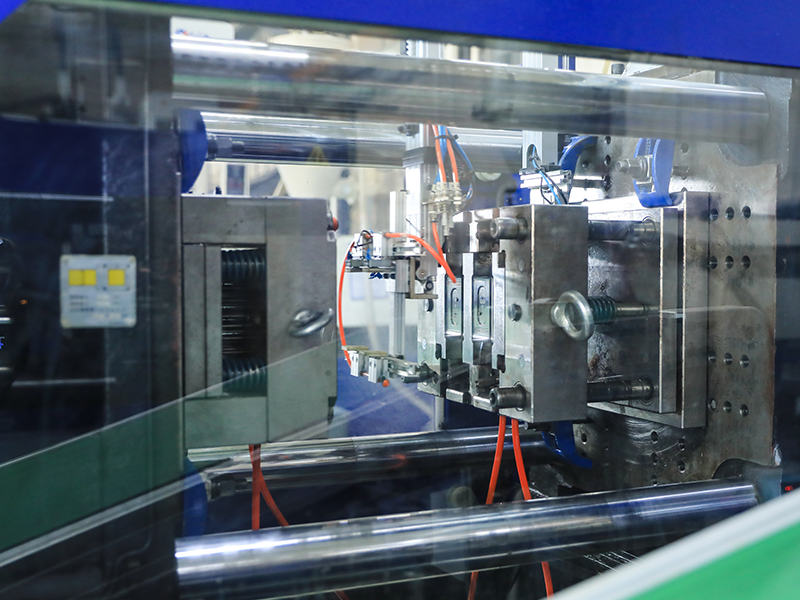

Next, the design and manufacture of injection molds is critical in determining the accuracy of medical injection molded parts. The mold must be precise and accurate to ensure that the part produced is a perfect match for the rest of the medical device. This requires mold designers to have great skill and extreme attention to detail. Every tiny imperfection can affect the functionality of the final product, so the mold must be perfected with every grind and polish.

Temperature control is also a non-negligible part of the medical injection molding process. Medical injection molded parts often have extremely high requirements for dimensional stability, and any thermal expansion or contraction can lead to part failure. Therefore, the temperature control system of the injection molding machine must be precise to ensure that the temperature of the plastic is uniform during the injection and cooling process.

In addition, optimization of injection parameters is an important means of improving product quality. Parameters such as injection speed, pressure, back pressure, holding time, etc. need to be finely adjusted according to the specific material and product design. This requires operators to have rich experience and keen insight to find the best combination of production parameters through continuous testing and adjustment.

Finally, quality control is the top priority in the processing of medical injection molded parts. From raw material inspection to finished product shipment, every step of the process must be strictly controlled. This includes not only visual inspection, but also dimensional measurements, mechanical testing and biocompatibility testing, among many other indicators. Only by ensuring that each product meets the high standards of the medical industry can it be delivered for use in medical institutions.

Medical injection molded parts processing is a complex process that combines science, technology and art. It requires practitioners to have not only exquisite technology, but also a responsible attitude towards life. Every step of rigor and every bit of concentration is the guardian of patient safety. When we pursue the ultimate in this art, we are not only molding medical devices, but also guarding the health and peace of countless lives.

In the world of medical injection molded parts, every processing is a pursuit of precision and perfection. With the spirit of craftsmanship, let us contribute the best quality products to the medical industry and add to the health of mankind.

First, material selection is the foundation of medical injection molded part processing. Medical-grade plastics must meet strict biocompatibility and safety standards. This requires processors to have an in-depth understanding of the material's properties, including temperature resistance, chemical resistance, mechanical strength, and ability to withstand sterilization processes. Choosing the right material is the first step in ensuring product quality and patient safety.

Next, the design and manufacture of injection molds is critical in determining the accuracy of medical injection molded parts. The mold must be precise and accurate to ensure that the part produced is a perfect match for the rest of the medical device. This requires mold designers to have great skill and extreme attention to detail. Every tiny imperfection can affect the functionality of the final product, so the mold must be perfected with every grind and polish.

Temperature control is also a non-negligible part of the medical injection molding process. Medical injection molded parts often have extremely high requirements for dimensional stability, and any thermal expansion or contraction can lead to part failure. Therefore, the temperature control system of the injection molding machine must be precise to ensure that the temperature of the plastic is uniform during the injection and cooling process.

In addition, optimization of injection parameters is an important means of improving product quality. Parameters such as injection speed, pressure, back pressure, holding time, etc. need to be finely adjusted according to the specific material and product design. This requires operators to have rich experience and keen insight to find the best combination of production parameters through continuous testing and adjustment.

Finally, quality control is the top priority in the processing of medical injection molded parts. From raw material inspection to finished product shipment, every step of the process must be strictly controlled. This includes not only visual inspection, but also dimensional measurements, mechanical testing and biocompatibility testing, among many other indicators. Only by ensuring that each product meets the high standards of the medical industry can it be delivered for use in medical institutions.

Medical injection molded parts processing is a complex process that combines science, technology and art. It requires practitioners to have not only exquisite technology, but also a responsible attitude towards life. Every step of rigor and every bit of concentration is the guardian of patient safety. When we pursue the ultimate in this art, we are not only molding medical devices, but also guarding the health and peace of countless lives.

In the world of medical injection molded parts, every processing is a pursuit of precision and perfection. With the spirit of craftsmanship, let us contribute the best quality products to the medical industry and add to the health of mankind.