What should I pay attention to in the injection molding production process?

Release time:2024-03-01

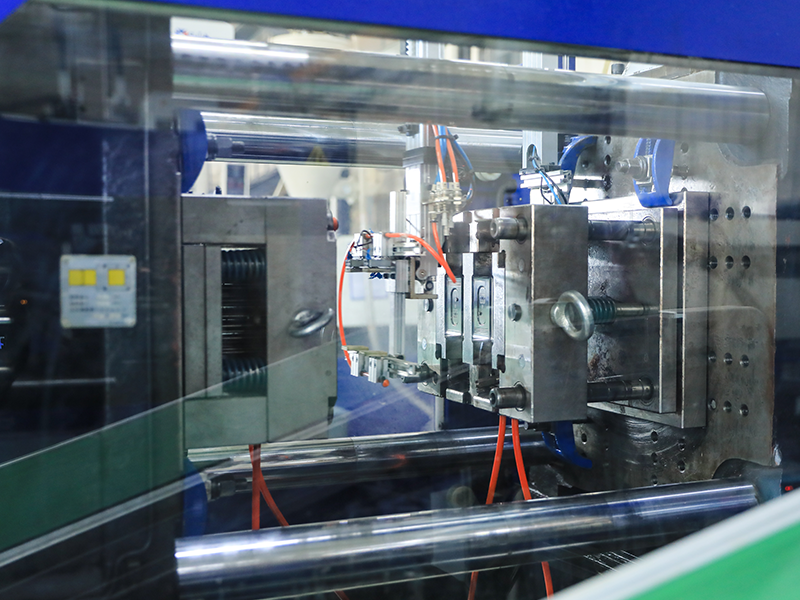

In the injection molding process, each part of the mold is the same. They have to fit tightly together. If the mold specification is not too good (such as axial force and shaped), it will damage the dimensional accuracy. After injection, the internal structure of the mold should have good air circulation and good cooling practical effect. If there are many tiny gaps or protrusions in the internal structure of the mold, they should be repaired immediately to prevent dry cracks or deformation.

First, you need to analyze the cause of such problems: in fact, if you stay in front for a long time, you can't shoot them out. At work, due to time difficulties, many empty mold plastic pellets dissolve again, so the injection is normal.