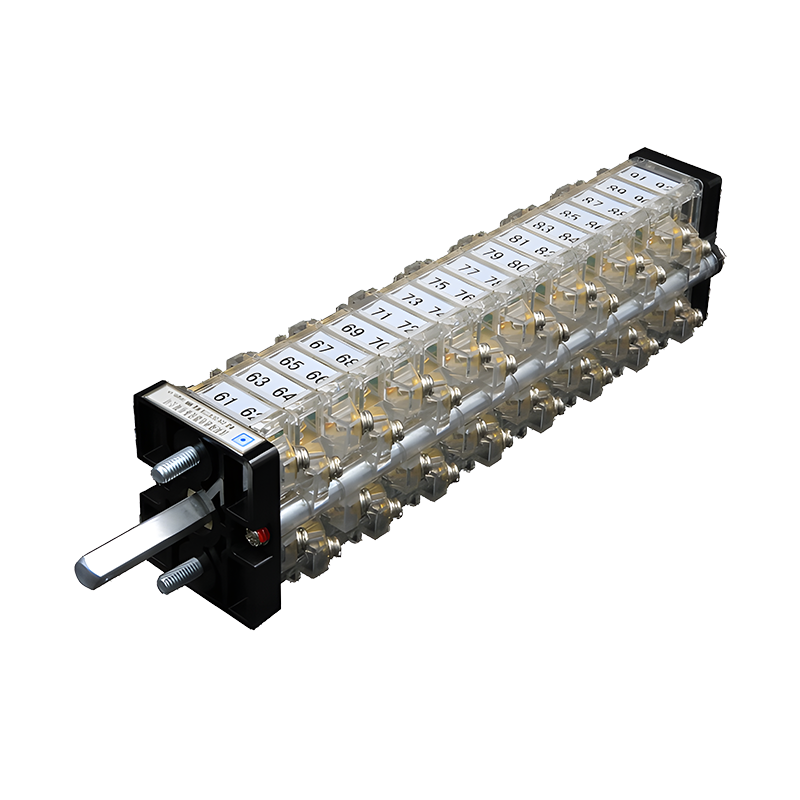

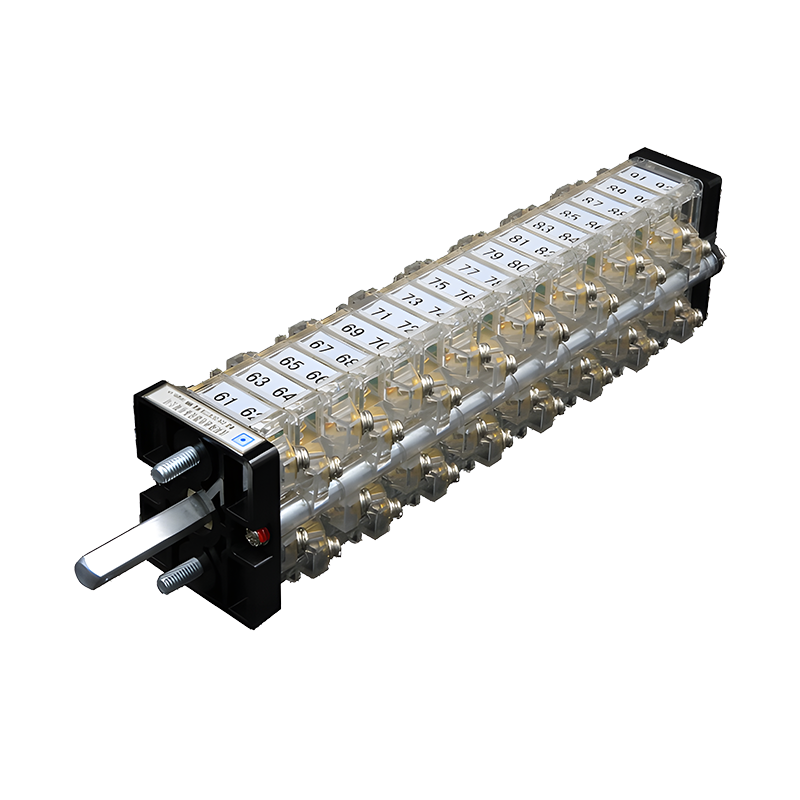

Important Functions and Roles of Auxiliary Switches in Spring Mechanisms

Release time:2024-02-26

Auxiliary switches in spring-loaded mechanisms play a vital role in ensuring the proper

functioning of the machine as well as providing additional safety

measures. In this article, we will take a closer look at the functions

and roles of auxiliary switches in spring mechanisms and present you

with a detailed and comprehensive analysis.

First of all, the auxiliary switch in the spring mechanism can monitor the expansion and contraction status of the spring. As a common component in machinery and equipment, the expansion and contraction of the spring is critical to the normal operation of the machine. The auxiliary switch can sense the degree of expansion and contraction of the spring, timely feedback to the control system, so as to timely adjust the working state of the machine. This is essential to ensure the stability and efficiency of the machine.

Secondly, the auxiliary switch in the spring mechanism also plays the role of safety protection. The spring mechanism is often subjected to a great deal of force and pressure during the working process, and once an abnormal situation occurs, it may cause serious harm to the working environment and the operator. Auxiliary switches can cut off the power supply in time when an abnormality occurs in the spring mechanism to avoid further damage and accidents. They can monitor various signals from the machine, such as overload, overheat, short circuit, etc., and can quickly cut off the power supply to safeguard the safety of the working environment.

In addition, auxiliary switches can also realize the control and adjustment of the spring mechanism. The spring mechanism usually needs to be adjusted and controlled according to different working requirements. The auxiliary switch can monitor and control the operation of the spring mechanism according to the set parameters and requirements. By setting different switch positions and operating modes, different spring movement characteristics can be realized to meet different working requirements.

In addition, there are auxiliary switches with self-diagnostic and troubleshooting functions. They can automatically diagnose and troubleshoot the machine by detecting and analyzing the machine's working status and fault information. This is of great significance for improving the reliability and stability of the machine, which can reduce the maintenance time and cost and improve the efficiency and productivity of the machine.

In summary, the auxiliary switches in the spring mechanism play an important role in the normal operation and safety protection of the machine. They can monitor the expansion and contraction state of the spring, provide safety protection measures, realize the control and regulation of the machine, and have the function of self-diagnosis and fault troubleshooting. Therefore, when designing and using spring mechanisms, the selection and configuration of auxiliary switches must be fully considered to ensure the stability, safety and efficiency of the machine.

First of all, the auxiliary switch in the spring mechanism can monitor the expansion and contraction status of the spring. As a common component in machinery and equipment, the expansion and contraction of the spring is critical to the normal operation of the machine. The auxiliary switch can sense the degree of expansion and contraction of the spring, timely feedback to the control system, so as to timely adjust the working state of the machine. This is essential to ensure the stability and efficiency of the machine.

Secondly, the auxiliary switch in the spring mechanism also plays the role of safety protection. The spring mechanism is often subjected to a great deal of force and pressure during the working process, and once an abnormal situation occurs, it may cause serious harm to the working environment and the operator. Auxiliary switches can cut off the power supply in time when an abnormality occurs in the spring mechanism to avoid further damage and accidents. They can monitor various signals from the machine, such as overload, overheat, short circuit, etc., and can quickly cut off the power supply to safeguard the safety of the working environment.

In addition, auxiliary switches can also realize the control and adjustment of the spring mechanism. The spring mechanism usually needs to be adjusted and controlled according to different working requirements. The auxiliary switch can monitor and control the operation of the spring mechanism according to the set parameters and requirements. By setting different switch positions and operating modes, different spring movement characteristics can be realized to meet different working requirements.

In addition, there are auxiliary switches with self-diagnostic and troubleshooting functions. They can automatically diagnose and troubleshoot the machine by detecting and analyzing the machine's working status and fault information. This is of great significance for improving the reliability and stability of the machine, which can reduce the maintenance time and cost and improve the efficiency and productivity of the machine.

In summary, the auxiliary switches in the spring mechanism play an important role in the normal operation and safety protection of the machine. They can monitor the expansion and contraction state of the spring, provide safety protection measures, realize the control and regulation of the machine, and have the function of self-diagnosis and fault troubleshooting. Therefore, when designing and using spring mechanisms, the selection and configuration of auxiliary switches must be fully considered to ensure the stability, safety and efficiency of the machine.