What are the steps of injection molding process?

Release time:2024-01-30

In the world of plastics, injection molding is an art, a magic that transforms particles into a thousand different forms. It is not just a manufacturing process, but a creative process, a process of visualization of the imagination. Today, let's go into this world of infinite possibilities and explore the mysteries of injection molding.

The first thing we need to understand is the core steps of injection molding. It is a carefully choreographed dance, where every movement is vital and every detail cannot be overlooked.

The first step is design. In this part, designers transform ideas into drawings and coalesce inspiration into shapes. They not only have to consider the beauty of the product, but also its practicality, making sure that every corner can carry its function.

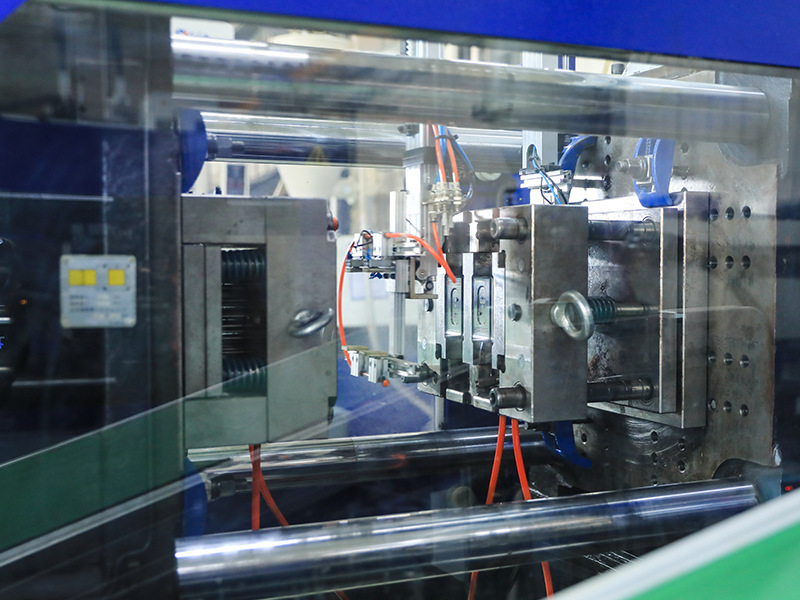

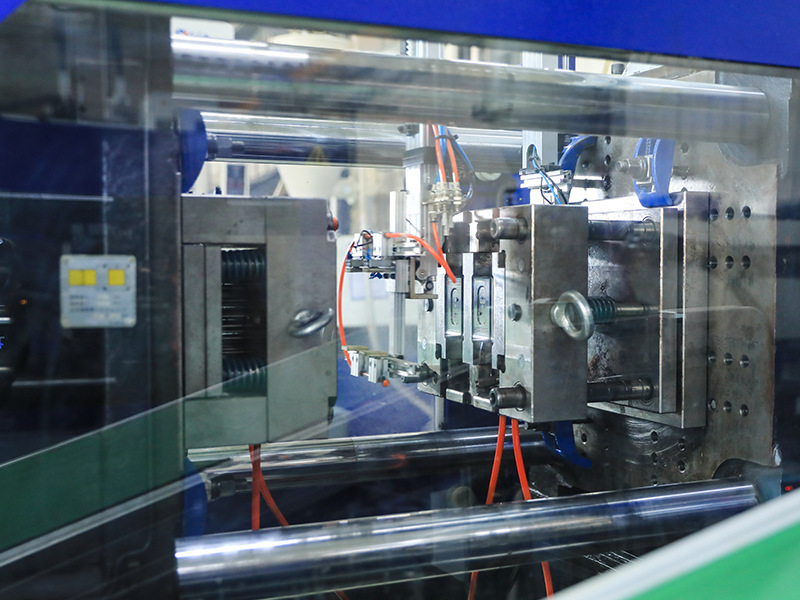

The second step is mold making. This is a crucial step in bringing the design from paper to reality. With great skill, mold makers carve steel into precise molds that breathe life into the framework of the plastic.

The third step is the preparation of the plastic material. In this part of the process, choosing the right plastic material is crucial. Different materials, with different properties, will determine the quality and performance of the final product.

The fourth step is the operation of the injection molding machine. This is the most critical step in the whole process. The operator must precisely control the temperature, pressure and time to ensure that the plastic can evenly and fully fill the mold to form a perfect product.

The fifth step is cooling and demolding. During this process, the plastic needs to cool and cure in the mold before it can be carefully removed from it. This step requires patience and care, and any impatience may result in a defective product.

The sixth step is post-processing. This includes a series of processes such as deburring, sanding, painting, etc. They make the product more perfect and more in line with the needs of use.

The last step is quality inspection. In this section, each product is rigorously inspected to ensure that they meet the highest quality standards. Only after passing this hurdle, the products can really go to the market, to the hands of consumers.

Injection molding processing, is a complex and delicate process. It requires the combination of technology and art, and the collision of science and creativity. In this process, every person is an artist, and every product is a work of art. When we use these plastic products in our daily life, perhaps we can imagine what extraordinary stories are behind these ordinary objects.

The first thing we need to understand is the core steps of injection molding. It is a carefully choreographed dance, where every movement is vital and every detail cannot be overlooked.

The first step is design. In this part, designers transform ideas into drawings and coalesce inspiration into shapes. They not only have to consider the beauty of the product, but also its practicality, making sure that every corner can carry its function.

The second step is mold making. This is a crucial step in bringing the design from paper to reality. With great skill, mold makers carve steel into precise molds that breathe life into the framework of the plastic.

The third step is the preparation of the plastic material. In this part of the process, choosing the right plastic material is crucial. Different materials, with different properties, will determine the quality and performance of the final product.

The fourth step is the operation of the injection molding machine. This is the most critical step in the whole process. The operator must precisely control the temperature, pressure and time to ensure that the plastic can evenly and fully fill the mold to form a perfect product.

The fifth step is cooling and demolding. During this process, the plastic needs to cool and cure in the mold before it can be carefully removed from it. This step requires patience and care, and any impatience may result in a defective product.

The sixth step is post-processing. This includes a series of processes such as deburring, sanding, painting, etc. They make the product more perfect and more in line with the needs of use.

The last step is quality inspection. In this section, each product is rigorously inspected to ensure that they meet the highest quality standards. Only after passing this hurdle, the products can really go to the market, to the hands of consumers.

Injection molding processing, is a complex and delicate process. It requires the combination of technology and art, and the collision of science and creativity. In this process, every person is an artist, and every product is a work of art. When we use these plastic products in our daily life, perhaps we can imagine what extraordinary stories are behind these ordinary objects.