Requirements and Precautions for Injection Mold Assembly

Release time:2024-01-22

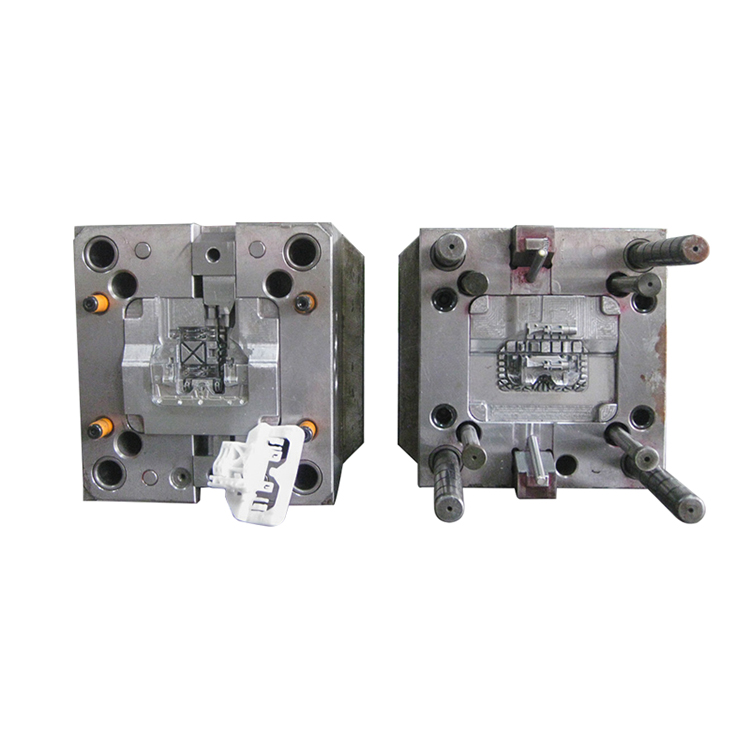

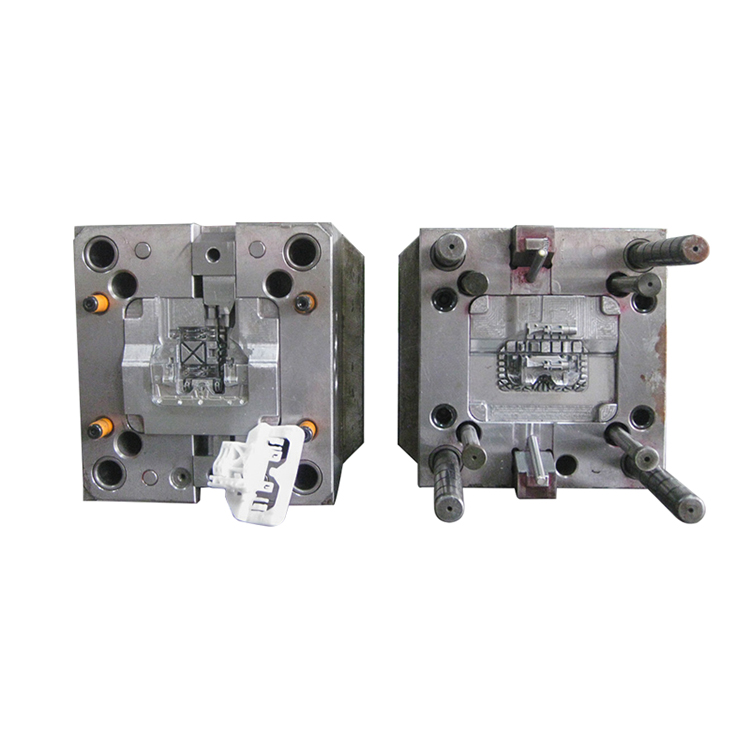

The assembly of injection mold refers to the process of assembling the parts into components according to the technical requirements of the injection mold, and then assembling the mold. Mold assembly process includes trial assembly, research and matching, adjustment, mold testing and other work. Through the assembly process, to achieve the production of qualified plastic products. The following precision injection mold manufacturer for you to explain injection mold assembly must meet the requirements of assembly accuracy.

1) Positional accuracy: the mutual positional accuracy of the parts and components, such as dimensional accuracy, coaxiality, parallelism, perpendicularity and so on.

2)Matching accuracy: the accuracy of the matching surfaces of the parts and components, such as a certain matching gap, the contact area of the match.

3) Motion precision: linear motion precision, rotary motion precision, transmission precision, etc..

Precision injection mold manufacturers

In the mold assembly should pay attention to the following aspects.

1) molding parts and pouring system. Molding parts of the shape, size must meet the requirements of the drawing; molding parts and pouring system surface should be flat, clean: contact with each other pressure parts should be appropriate clearance or reasonable pressure area. Cavity of the parting surface, the gate and the inlet should be maintained at the sharp edges, generally do not repair rounded corners.

2) launch system parts. Launch the system in the injection mold can be smoothly launched when the mold is open, and easy to take out the parts and waste. Closed mold can accurately return to the initial position; the launch parts, after assembly to move smoothly and flexibly, there shall be no stagnation.

3) slider and moving parts. Ensure the assembly precision, to ensure the precision of movement, to ensure that the assembly is reliable.

4) guide mechanism. Guide pillar, guide sleeve after installation should be perpendicular to the mold base, not skewed: guide pillar, guide sleeve guiding accuracy to meet the requirements of the design drawings.

5) heating and cooling system. Cooling waterway should be smooth, no water leakage, valve control is reliable; electric heating system should be well insulated, no leakage phenomenon and safe and reliable, can achieve the requirements of the injection mold temperature.

6) injection mold appearance. For the handling, installation convenience, injection molds should be equipped with lifting holes or rings; mold assembly after the closing height, installation dimensions in line with the requirements of the design drawings; mold closure, the parting surface, between the pressure surface to be closed tightly. Mold exposed part of the edges to be chamfered; mold assembly after moving, fixed mold seat plate mounting face parting surface parallelism in the range of 300mm is not greater than 0.05mm; assembled molds should be printed marking, numbering and mold marking; assembled molds, mold testing should be carried out under production conditions until the production of products to meet the quality requirements.

1) Positional accuracy: the mutual positional accuracy of the parts and components, such as dimensional accuracy, coaxiality, parallelism, perpendicularity and so on.

2)Matching accuracy: the accuracy of the matching surfaces of the parts and components, such as a certain matching gap, the contact area of the match.

3) Motion precision: linear motion precision, rotary motion precision, transmission precision, etc..

Precision injection mold manufacturers

In the mold assembly should pay attention to the following aspects.

1) molding parts and pouring system. Molding parts of the shape, size must meet the requirements of the drawing; molding parts and pouring system surface should be flat, clean: contact with each other pressure parts should be appropriate clearance or reasonable pressure area. Cavity of the parting surface, the gate and the inlet should be maintained at the sharp edges, generally do not repair rounded corners.

2) launch system parts. Launch the system in the injection mold can be smoothly launched when the mold is open, and easy to take out the parts and waste. Closed mold can accurately return to the initial position; the launch parts, after assembly to move smoothly and flexibly, there shall be no stagnation.

3) slider and moving parts. Ensure the assembly precision, to ensure the precision of movement, to ensure that the assembly is reliable.

4) guide mechanism. Guide pillar, guide sleeve after installation should be perpendicular to the mold base, not skewed: guide pillar, guide sleeve guiding accuracy to meet the requirements of the design drawings.

5) heating and cooling system. Cooling waterway should be smooth, no water leakage, valve control is reliable; electric heating system should be well insulated, no leakage phenomenon and safe and reliable, can achieve the requirements of the injection mold temperature.

6) injection mold appearance. For the handling, installation convenience, injection molds should be equipped with lifting holes or rings; mold assembly after the closing height, installation dimensions in line with the requirements of the design drawings; mold closure, the parting surface, between the pressure surface to be closed tightly. Mold exposed part of the edges to be chamfered; mold assembly after moving, fixed mold seat plate mounting face parting surface parallelism in the range of 300mm is not greater than 0.05mm; assembled molds should be printed marking, numbering and mold marking; assembled molds, mold testing should be carried out under production conditions until the production of products to meet the quality requirements.