What are the key technologies in stamping mold processing?

Release time:2024-01-22

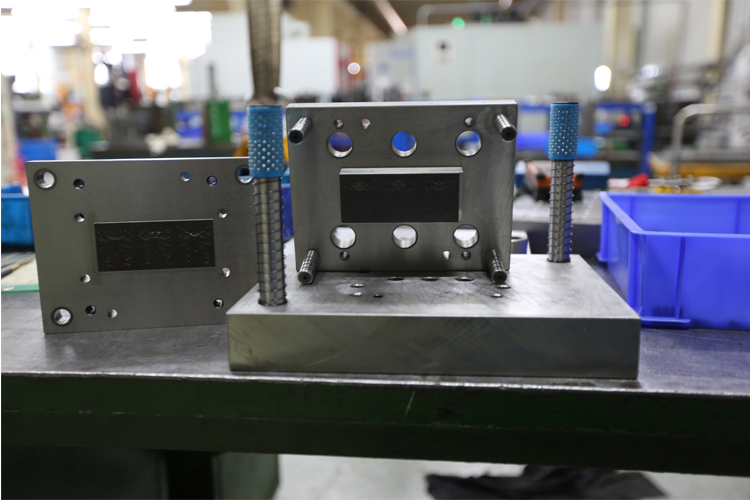

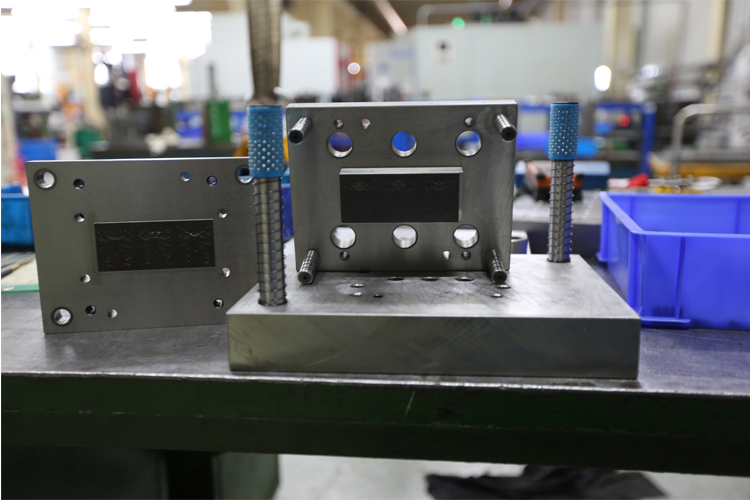

Stamping die processing is a common processing method in modern manufacturing industry, with the characteristics of good repeatability. In the process of stamping die processing, there are some key technologies, which are important for improving product quality and production efficiency. The following will introduce the key technologies in stamping mold processing.

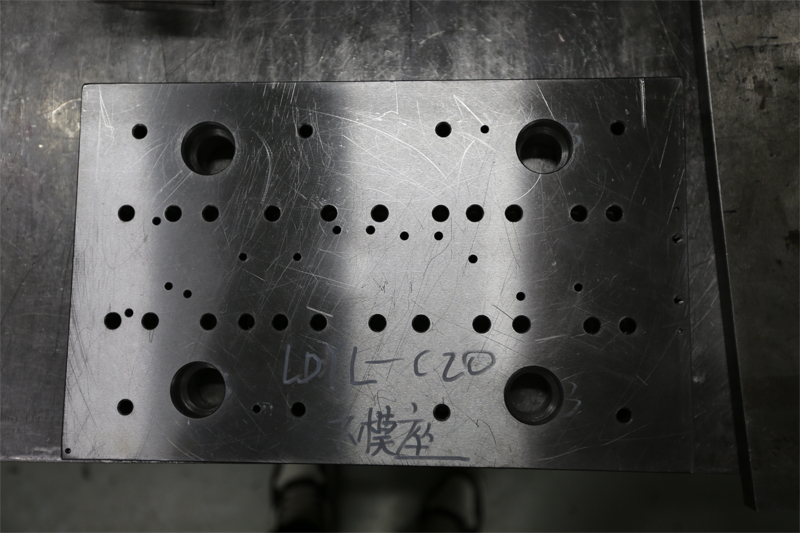

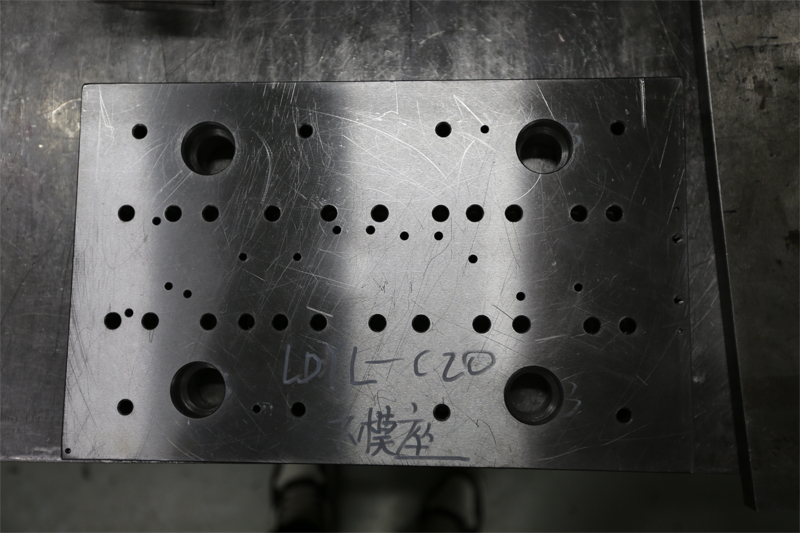

Material selection and heat treatment technology: in stamping die processing, the selection of mold materials is very important. Mold materials should have high strength, high hardness, wear resistance and fatigue resistance, etc., in order to ensure that the mold in a long time under high load work stability. At the same time, for the nature of the mold material, take appropriate heat treatment process, improve the hardness and wear resistance of the mold.

Design technology: the design of stamping die is an important part of stamping processing. Mold design can make the processing of products more stable. In the process of die design, it is necessary to take into account the shape, structure and size of the product and other factors, and reasonably design the structure of the die in order to achieve high-precision processing and to reduce the waste of materials and the consumption of the die.

Manufacturing process: The manufacturing process of stamping mold plays an important role in improving product quality and production efficiency. First of all, it is necessary to develop a reasonable processing technology, including processing sequence, processing methods and processing parameters. Secondly, for some complex mold configuration, also need to use advanced processing technology, such as electric discharge machining, laser processing and CNC machining, etc., in order to improve manufacturing accuracy and efficiency.

Surface treatment technology: In the process of stamping die processing, the surface quality and lubricity of the die has an important impact on the molding quality and processing effect of the product. Therefore, after the mold processing is completed, appropriate surface treatment is needed to improve the wear resistance of the mold and reduce the friction coefficient. Commonly used surface treatment technologies include electroplating, spraying and carburizing.

Material selection and heat treatment technology: in stamping die processing, the selection of mold materials is very important. Mold materials should have high strength, high hardness, wear resistance and fatigue resistance, etc., in order to ensure that the mold in a long time under high load work stability. At the same time, for the nature of the mold material, take appropriate heat treatment process, improve the hardness and wear resistance of the mold.

Design technology: the design of stamping die is an important part of stamping processing. Mold design can make the processing of products more stable. In the process of die design, it is necessary to take into account the shape, structure and size of the product and other factors, and reasonably design the structure of the die in order to achieve high-precision processing and to reduce the waste of materials and the consumption of the die.

Manufacturing process: The manufacturing process of stamping mold plays an important role in improving product quality and production efficiency. First of all, it is necessary to develop a reasonable processing technology, including processing sequence, processing methods and processing parameters. Secondly, for some complex mold configuration, also need to use advanced processing technology, such as electric discharge machining, laser processing and CNC machining, etc., in order to improve manufacturing accuracy and efficiency.

Surface treatment technology: In the process of stamping die processing, the surface quality and lubricity of the die has an important impact on the molding quality and processing effect of the product. Therefore, after the mold processing is completed, appropriate surface treatment is needed to improve the wear resistance of the mold and reduce the friction coefficient. Commonly used surface treatment technologies include electroplating, spraying and carburizing.