The Amazing Journey of Injection Molding Processing

Release time:2024-01-17

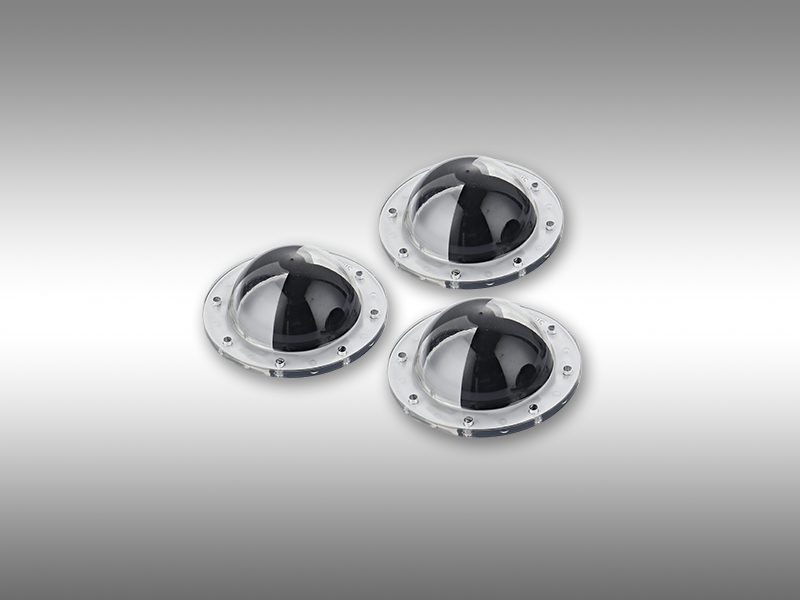

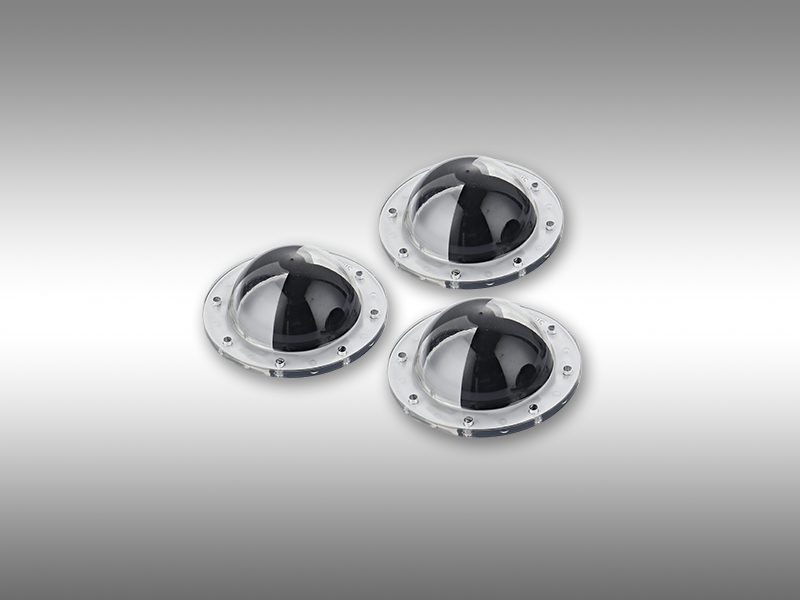

In the world of manufacturing, injection molding processing is a common manufacturing process that has earned wide adoption for its efficiency, precision and versatility. However, the process of injection molding processing remains a mysterious and complex area for most people. Today, let's step into this wonderful world and explore the mysteries of injection molding processing.

The first thing we need to understand is that the process of injection molding is actually a process of injecting molten plastic into a mold, then cooling and curing it, and finally removing the molded product. This process may seem simple, but it actually involves many delicate operations and strict control.

At the beginning of the injection molding process, workers place plastic pellets into the hopper of the injection molding machine. These pellets are heated and transformed into molten plastic. This process requires precise temperature control to ensure that the molten plastic is optimized.

Next, the molten plastic is injected into a pre-designed mold. The shape and size of this mold determines the shape and size of the final product. This process requires precise pressure control to ensure that the plastic fills every corner of the mold.

The molten plastic then cools and solidifies in the mold to form the shape of the product we want. This process requires precise time control to ensure the quality and performance of the product.

Finally, when the product is completely cooled and cured, workers remove it from the mold. This process requires precise force control to prevent damage to the product during removal.

The process of injection molding processing is complicated, but through precise control and operation, we can make a wide variety of products to meet different needs. This is the charm of injection molding processing.

Every part of the process is full of challenges and opportunities. Whether it is the control of temperature, pressure, time, or force, we need to have enough professional knowledge and skills. And these knowledge and skills are the result of our continuous learning and improvement in the process of injection molding processing.

Overall, the process of injection molding processing is a journey full of challenges and opportunities. It requires us to have sufficient professional knowledge and skills, as well as a rigorous grasp of details. Only then can we succeed in this journey and create high quality products.

The first thing we need to understand is that the process of injection molding is actually a process of injecting molten plastic into a mold, then cooling and curing it, and finally removing the molded product. This process may seem simple, but it actually involves many delicate operations and strict control.

At the beginning of the injection molding process, workers place plastic pellets into the hopper of the injection molding machine. These pellets are heated and transformed into molten plastic. This process requires precise temperature control to ensure that the molten plastic is optimized.

Next, the molten plastic is injected into a pre-designed mold. The shape and size of this mold determines the shape and size of the final product. This process requires precise pressure control to ensure that the plastic fills every corner of the mold.

The molten plastic then cools and solidifies in the mold to form the shape of the product we want. This process requires precise time control to ensure the quality and performance of the product.

Finally, when the product is completely cooled and cured, workers remove it from the mold. This process requires precise force control to prevent damage to the product during removal.

The process of injection molding processing is complicated, but through precise control and operation, we can make a wide variety of products to meet different needs. This is the charm of injection molding processing.

Every part of the process is full of challenges and opportunities. Whether it is the control of temperature, pressure, time, or force, we need to have enough professional knowledge and skills. And these knowledge and skills are the result of our continuous learning and improvement in the process of injection molding processing.

Overall, the process of injection molding processing is a journey full of challenges and opportunities. It requires us to have sufficient professional knowledge and skills, as well as a rigorous grasp of details. Only then can we succeed in this journey and create high quality products.