The Fine Way to Process Medical Injection Molded Parts

Release time:2024-01-09

Injection molded parts have become an integral part of the modern medical field. From simple medical devices to complex medical equipment, injection molded parts are used everywhere. However, the processing of medical injection molded parts is not an easy task, it requires strict quality control and fine operating skills. So, what are the key factors we should pay attention to when processing medical injection molded parts?

The first thing we need to pay attention to is the selection of raw materials. The quality of medical injection molded parts is directly related to the health and life safety of patients, so we must choose raw materials that meet the medical grade. These raw materials need to undergo strict screening and testing to ensure their purity, stability and biocompatibility. At the same time, we also need to conduct regular quality checks on the raw materials to prevent any possible contamination and quality problems.

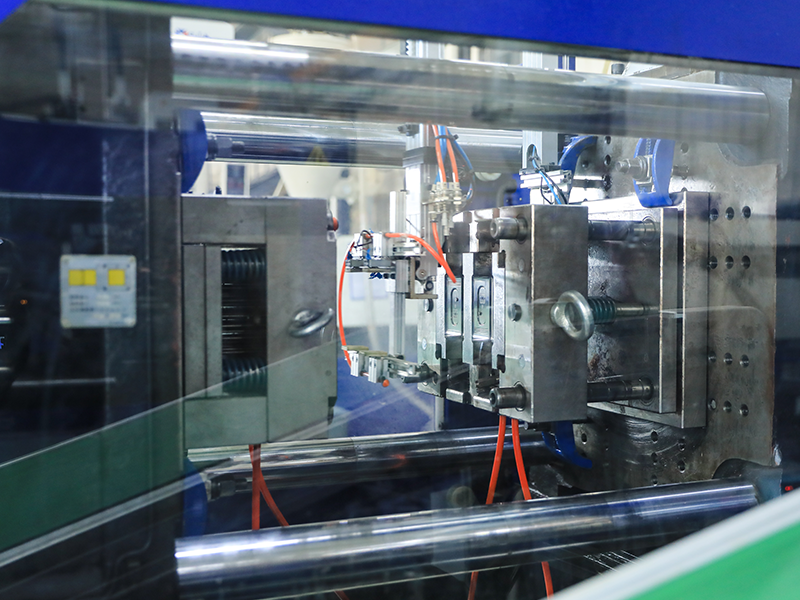

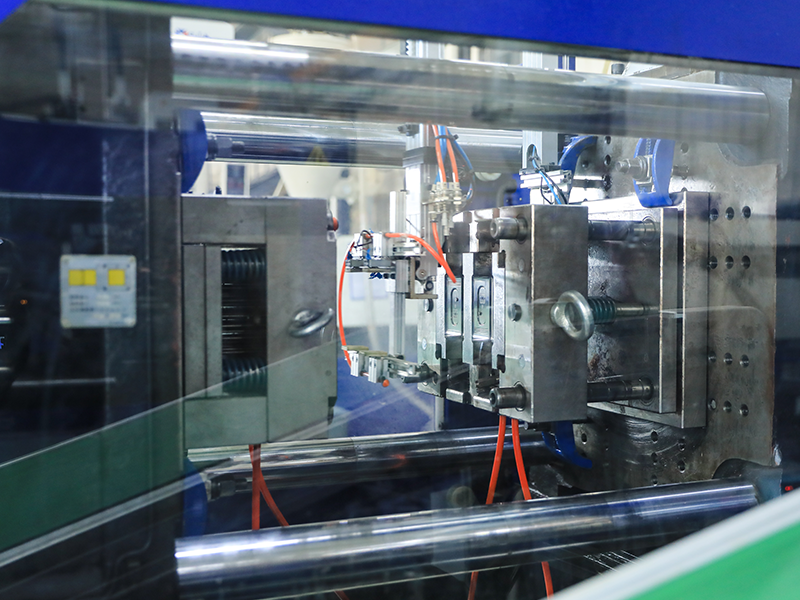

Secondly, we need to strictly control the production process. The production process of medical injection molded parts requires precise temperature control, pressure control and time control. Any small deviation may lead to product quality problems. Therefore, we need to use advanced production equipment and technology to ensure the stability and controllability of the production process. At the same time, we also need to regularly maintain and calibrate the production equipment to prevent equipment failures and errors.

Again, we need to pay attention to the post-treatment process of the product. Medical injection molded parts need to be strictly cleaned, sterilized and packaged after production. These steps can not only ensure the safety of the product, but also extend the service life of the product. Therefore, we need to use professional cleaners and disinfectants to ensure the cleanliness and safety of the products. Meanwhile, we also need to use high-quality packaging materials to protect the products from damage during transportation.

Finally, we need to establish a perfect quality management system. The processing of medical injection molded parts is a complex process, involving multiple links and multiple personnel. Therefore, we need to establish a complete quality management system to ensure that each link and each person can operate in accordance with the required standards. At the same time, we also need to conduct regular quality audits and quality improvement to continuously improve our product quality and productivity.

Overall, the processing of medical injection molded parts is a rigorous job that requires us to invest a lot of time and effort. However, only in this way can we produce high-quality medical injection molded parts and provide better medical services for patients.

The first thing we need to pay attention to is the selection of raw materials. The quality of medical injection molded parts is directly related to the health and life safety of patients, so we must choose raw materials that meet the medical grade. These raw materials need to undergo strict screening and testing to ensure their purity, stability and biocompatibility. At the same time, we also need to conduct regular quality checks on the raw materials to prevent any possible contamination and quality problems.

Secondly, we need to strictly control the production process. The production process of medical injection molded parts requires precise temperature control, pressure control and time control. Any small deviation may lead to product quality problems. Therefore, we need to use advanced production equipment and technology to ensure the stability and controllability of the production process. At the same time, we also need to regularly maintain and calibrate the production equipment to prevent equipment failures and errors.

Again, we need to pay attention to the post-treatment process of the product. Medical injection molded parts need to be strictly cleaned, sterilized and packaged after production. These steps can not only ensure the safety of the product, but also extend the service life of the product. Therefore, we need to use professional cleaners and disinfectants to ensure the cleanliness and safety of the products. Meanwhile, we also need to use high-quality packaging materials to protect the products from damage during transportation.

Finally, we need to establish a perfect quality management system. The processing of medical injection molded parts is a complex process, involving multiple links and multiple personnel. Therefore, we need to establish a complete quality management system to ensure that each link and each person can operate in accordance with the required standards. At the same time, we also need to conduct regular quality audits and quality improvement to continuously improve our product quality and productivity.

Overall, the processing of medical injection molded parts is a rigorous job that requires us to invest a lot of time and effort. However, only in this way can we produce high-quality medical injection molded parts and provide better medical services for patients.