Stamping Die Processing Tips - Make your work more efficient!

Release time:2024-01-04

Stamping dies are an indispensable tool in the manufacturing industry. They are widely used in the production of a variety of products, from car parts to household appliances, to electronic equipment, can not do without the help of stamping molds. However, stamping mold processing is not an easy task and requires certain skills and experience. Today, I will share with you some stamping mold processing skills to help you improve efficiency and product quality.

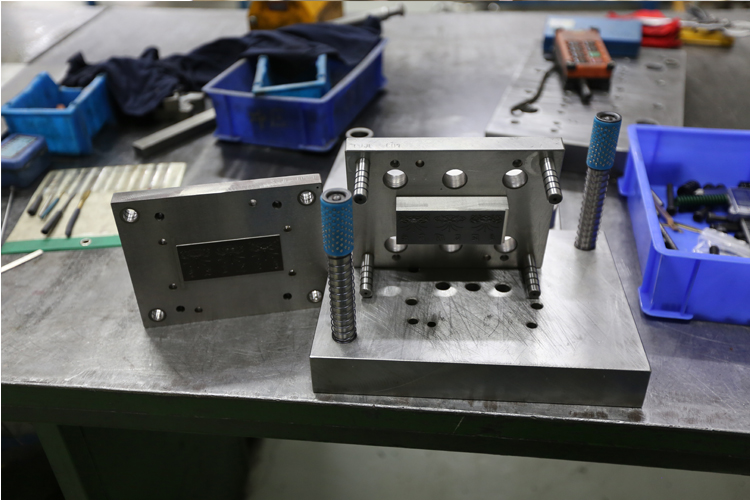

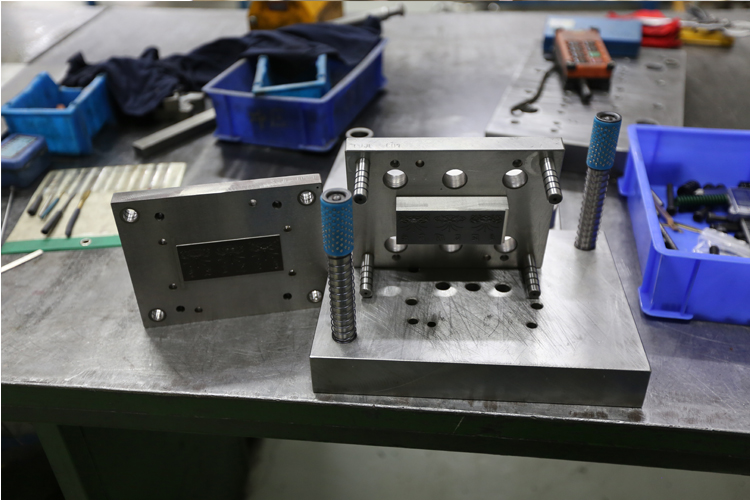

First of all, we need to understand the basic structure of stamping mold. Stamping die is mainly composed of three parts: upper die, lower die and guide device. The upper die is the punch, the lower die is the concave die, the guide is used to ensure that the upper and lower dies are accurately aligned. During the processing, we need to ensure the accuracy and quality of these three parts, otherwise it will affect the quality of the final product.

Next, let's talk about the skills of stamping mold processing.

1. Choose the right material: the material of stamping die directly affects its service life and processing effect. Generally speaking, we will choose materials with high hardness and good wear resistance, such as Cr12MoV and D2.

2. Accurate Measurement: In the process of processing, we need to carry out accurate measurement of each part of the mold to ensure its dimensional accuracy. This requires the use of professional measuring tools, such as micrometers, micrometer, etc.

3. Fine grinding: after the mold processing is completed, we need to carry out fine grinding, remove surface burrs and defects, improve the surface quality of the mold.

4. Regular maintenance: Stamping molds need regular maintenance in the process of use, including cleaning, lubrication, inspection, etc., in order to extend their service life.

5. Innovative design: under the premise of meeting the product demand, we can try to make innovations in die design, such as adopting new type of guiding device, optimizing the die structure, etc., in order to improve the processing efficiency and product quality.

In general, stamping mold processing is a highly technical work, we need to constantly learn and practice. Only in this way can we master more skills, improve work efficiency and enhance product quality. Let us together on the road of stamping die processing continue to move forward!

First of all, we need to understand the basic structure of stamping mold. Stamping die is mainly composed of three parts: upper die, lower die and guide device. The upper die is the punch, the lower die is the concave die, the guide is used to ensure that the upper and lower dies are accurately aligned. During the processing, we need to ensure the accuracy and quality of these three parts, otherwise it will affect the quality of the final product.

Next, let's talk about the skills of stamping mold processing.

1. Choose the right material: the material of stamping die directly affects its service life and processing effect. Generally speaking, we will choose materials with high hardness and good wear resistance, such as Cr12MoV and D2.

2. Accurate Measurement: In the process of processing, we need to carry out accurate measurement of each part of the mold to ensure its dimensional accuracy. This requires the use of professional measuring tools, such as micrometers, micrometer, etc.

3. Fine grinding: after the mold processing is completed, we need to carry out fine grinding, remove surface burrs and defects, improve the surface quality of the mold.

4. Regular maintenance: Stamping molds need regular maintenance in the process of use, including cleaning, lubrication, inspection, etc., in order to extend their service life.

5. Innovative design: under the premise of meeting the product demand, we can try to make innovations in die design, such as adopting new type of guiding device, optimizing the die structure, etc., in order to improve the processing efficiency and product quality.

In general, stamping mold processing is a highly technical work, we need to constantly learn and practice. Only in this way can we master more skills, improve work efficiency and enhance product quality. Let us together on the road of stamping die processing continue to move forward!