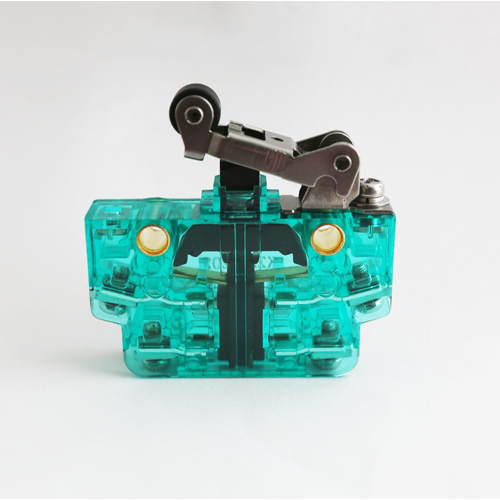

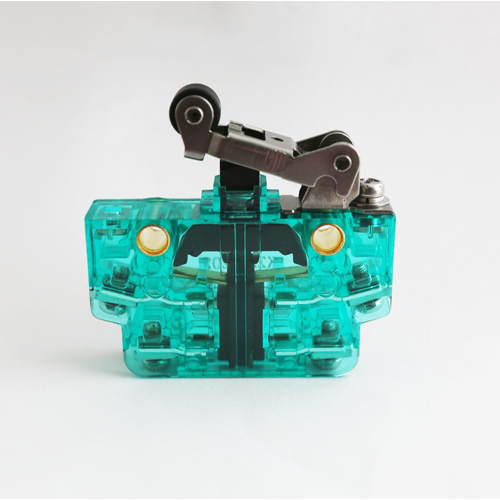

Performance and reliability of microswitches: key strategies for improvement

Release time:2023-12-29

In the world of modern technology, microswitches have become an integral part of our daily lives. They are found in a wide range of devices, from household appliances to automobiles and even aerospace equipment. However, with the continuous development of science and technology and the growing market demand, how to improve the performance and reliability of microswitches has become an important topic.

First of all, we need to understand what is the performance and reliability of microswitches. Simply put, performance refers to how well a microswitch works under specific conditions, while reliability refers to the stability and durability of a microswitch during long-term use. The two go hand in hand, and an excellent microswitch needs to be highly reliable while ensuring performance.

So how do you improve the performance and reliability of a microswitch? This requires us to consider the following aspects:

1. Material selection: The performance and reliability of microswitches depend largely on the materials they are made of. Therefore, we need to choose materials with good electrical conductivity, heat resistance and corrosion resistance. At the same time, we also need to consider the strength and hardness of the material to ensure that the microswitch in the long-term use of the process will not be due to material fatigue and lead to performance degradation.

2. Design optimization: The design of microswitches is also an important factor that affects their performance and reliability. We need to reduce unnecessary parts and simplify the structure by optimizing the design in order to improve the working efficiency of the microswitch. At the same time, we also need to consider the working environment of the microswitch, such as temperature, humidity, etc., to ensure that it can work properly in various environments.

3. Manufacturing process: The manufacturing process of microswitch will also affect its performance and reliability. We need to use advanced manufacturing process, such as precision casting, precision stamping, etc., to ensure the accuracy and consistency of the microswitch. At the same time, we also need to carry out strict quality control to ensure that each microswitch meets the performance and reliability standards we set.

4. Testing and Verification: Finally, we need to conduct strict testing and verification of the microswitches to ensure their performance and reliability. This includes static test, dynamic test, environmental adaptability test and so on. Only through these tests can we ensure that the microswitch can achieve the expected performance and reliability in actual use.

Overall, improving the performance and reliability of microswitches is a systematic project, which requires us to make comprehensive considerations from various aspects such as material selection, design optimization, manufacturing process, testing and verification. Only in this way, we can manufacture really excellent microswitches to meet the market demand and promote the development of science and technology.

First of all, we need to understand what is the performance and reliability of microswitches. Simply put, performance refers to how well a microswitch works under specific conditions, while reliability refers to the stability and durability of a microswitch during long-term use. The two go hand in hand, and an excellent microswitch needs to be highly reliable while ensuring performance.

So how do you improve the performance and reliability of a microswitch? This requires us to consider the following aspects:

1. Material selection: The performance and reliability of microswitches depend largely on the materials they are made of. Therefore, we need to choose materials with good electrical conductivity, heat resistance and corrosion resistance. At the same time, we also need to consider the strength and hardness of the material to ensure that the microswitch in the long-term use of the process will not be due to material fatigue and lead to performance degradation.

2. Design optimization: The design of microswitches is also an important factor that affects their performance and reliability. We need to reduce unnecessary parts and simplify the structure by optimizing the design in order to improve the working efficiency of the microswitch. At the same time, we also need to consider the working environment of the microswitch, such as temperature, humidity, etc., to ensure that it can work properly in various environments.

3. Manufacturing process: The manufacturing process of microswitch will also affect its performance and reliability. We need to use advanced manufacturing process, such as precision casting, precision stamping, etc., to ensure the accuracy and consistency of the microswitch. At the same time, we also need to carry out strict quality control to ensure that each microswitch meets the performance and reliability standards we set.

4. Testing and Verification: Finally, we need to conduct strict testing and verification of the microswitches to ensure their performance and reliability. This includes static test, dynamic test, environmental adaptability test and so on. Only through these tests can we ensure that the microswitch can achieve the expected performance and reliability in actual use.

Overall, improving the performance and reliability of microswitches is a systematic project, which requires us to make comprehensive considerations from various aspects such as material selection, design optimization, manufacturing process, testing and verification. Only in this way, we can manufacture really excellent microswitches to meet the market demand and promote the development of science and technology.