Solutions for excessive clearance in stamping die machining

Release time:2023-12-27

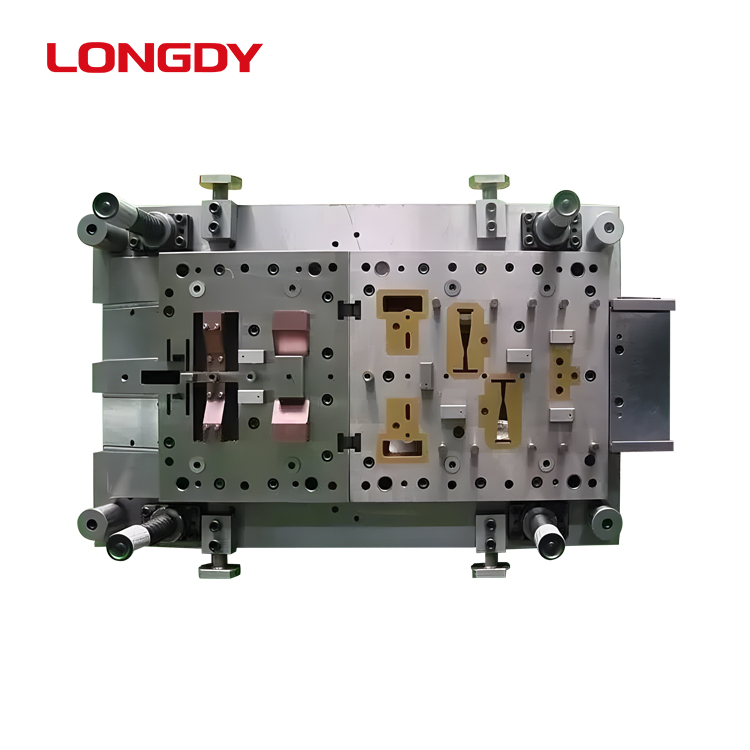

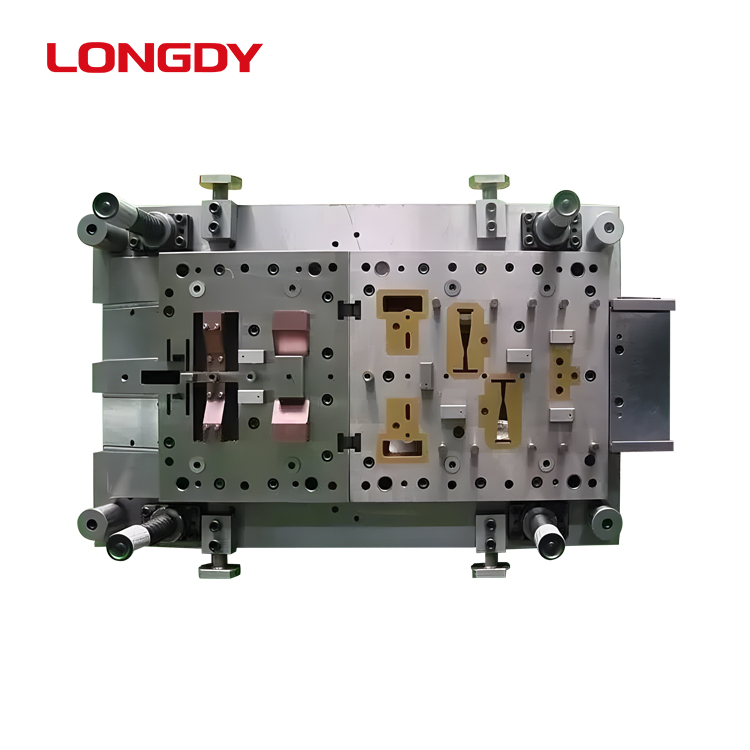

In manufacturing, stamping dies are a common tool used to produce parts of various shapes and sizes. However, when the machining clearance of stamping dies is too large, it may lead to a decrease in product quality and may even damage the dies. So, how should we deal with the problem of excessive machining clearance of stamping dies?

First of all, we need to clarify what is the gap of stamping die processing. Simply put, the processing gap refers to the mold in the closed state, the distance between the upper and lower mold. The size of this distance directly affects the dimensional accuracy and surface quality of the stamped part. If the machining clearance is too large, the dimensions of the stamped part may be out of tolerance, and the surface may have scratches or dents.

So, how to determine whether the gap of stamping die processing is too large? Generally speaking, we can judge it by measuring the size and surface quality of the stamped part. If we find that the dimensions of the stamped part are unstable, or the surface has obvious scratches or dents, then it may be that the clearance of the die processing is too large.

Facing the problem of excessive gap in stamping die processing, we can take the following solutions:

1. Adjust the mold: If the structure of the mold allows, we can reduce the processing gap by adjusting the position of the mold. This requires professional mold engineers to operate to ensure the stability and service life of the mold.

2. Replacement of mold: If the structure of the mold can not be adjusted, or still can not meet the production requirements after adjustment, then we may need to replace the mold with a new one. When replacing the mold, we need to choose the mold with high precision and good quality to ensure smooth production.

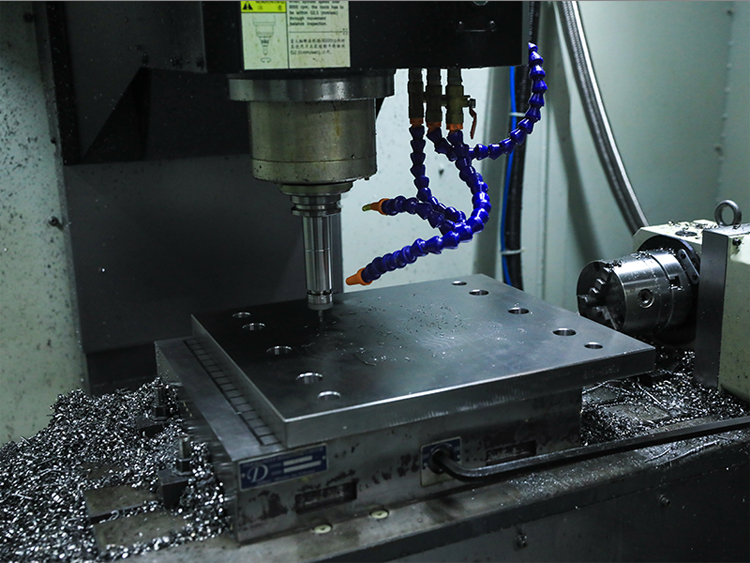

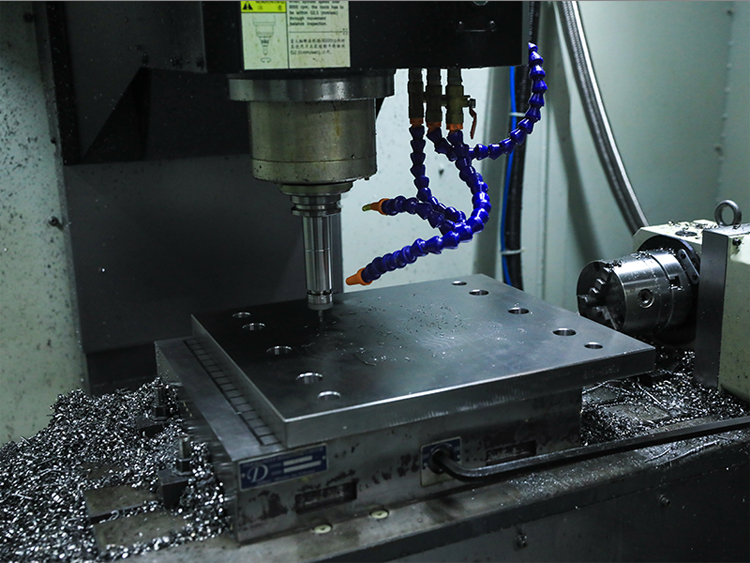

3. Optimize the production process: Besides adjusting the mold and replacing the mold, we can also optimize the production process to reduce the impact of machining clearance. For example, we can improve the dimensional accuracy and surface quality of stamped parts by improving the selection and treatment of materials or optimizing the parameters of stamping process.

Overall, the excessive processing gap of stamping die is a complex problem, which requires us to analyze and solve it from multiple perspectives. Only in this way can we ensure the normal operation of the stamping mold, improve production efficiency and product quality.

First of all, we need to clarify what is the gap of stamping die processing. Simply put, the processing gap refers to the mold in the closed state, the distance between the upper and lower mold. The size of this distance directly affects the dimensional accuracy and surface quality of the stamped part. If the machining clearance is too large, the dimensions of the stamped part may be out of tolerance, and the surface may have scratches or dents.

So, how to determine whether the gap of stamping die processing is too large? Generally speaking, we can judge it by measuring the size and surface quality of the stamped part. If we find that the dimensions of the stamped part are unstable, or the surface has obvious scratches or dents, then it may be that the clearance of the die processing is too large.

Facing the problem of excessive gap in stamping die processing, we can take the following solutions:

1. Adjust the mold: If the structure of the mold allows, we can reduce the processing gap by adjusting the position of the mold. This requires professional mold engineers to operate to ensure the stability and service life of the mold.

2. Replacement of mold: If the structure of the mold can not be adjusted, or still can not meet the production requirements after adjustment, then we may need to replace the mold with a new one. When replacing the mold, we need to choose the mold with high precision and good quality to ensure smooth production.

3. Optimize the production process: Besides adjusting the mold and replacing the mold, we can also optimize the production process to reduce the impact of machining clearance. For example, we can improve the dimensional accuracy and surface quality of stamped parts by improving the selection and treatment of materials or optimizing the parameters of stamping process.

Overall, the excessive processing gap of stamping die is a complex problem, which requires us to analyze and solve it from multiple perspectives. Only in this way can we ensure the normal operation of the stamping mold, improve production efficiency and product quality.