Automotive injection mold precision machining journey

Release time:2023-12-12

Automotive injection mold precision machining journey

In modern industrial production, automotive injection mold processing is a crucial task. They are not only the basis for the production of auto parts, but also a key factor in ensuring product quality. So, how is the automobile injection mold processed? Let's go into this sophisticated world and explore the mysteries behind it.

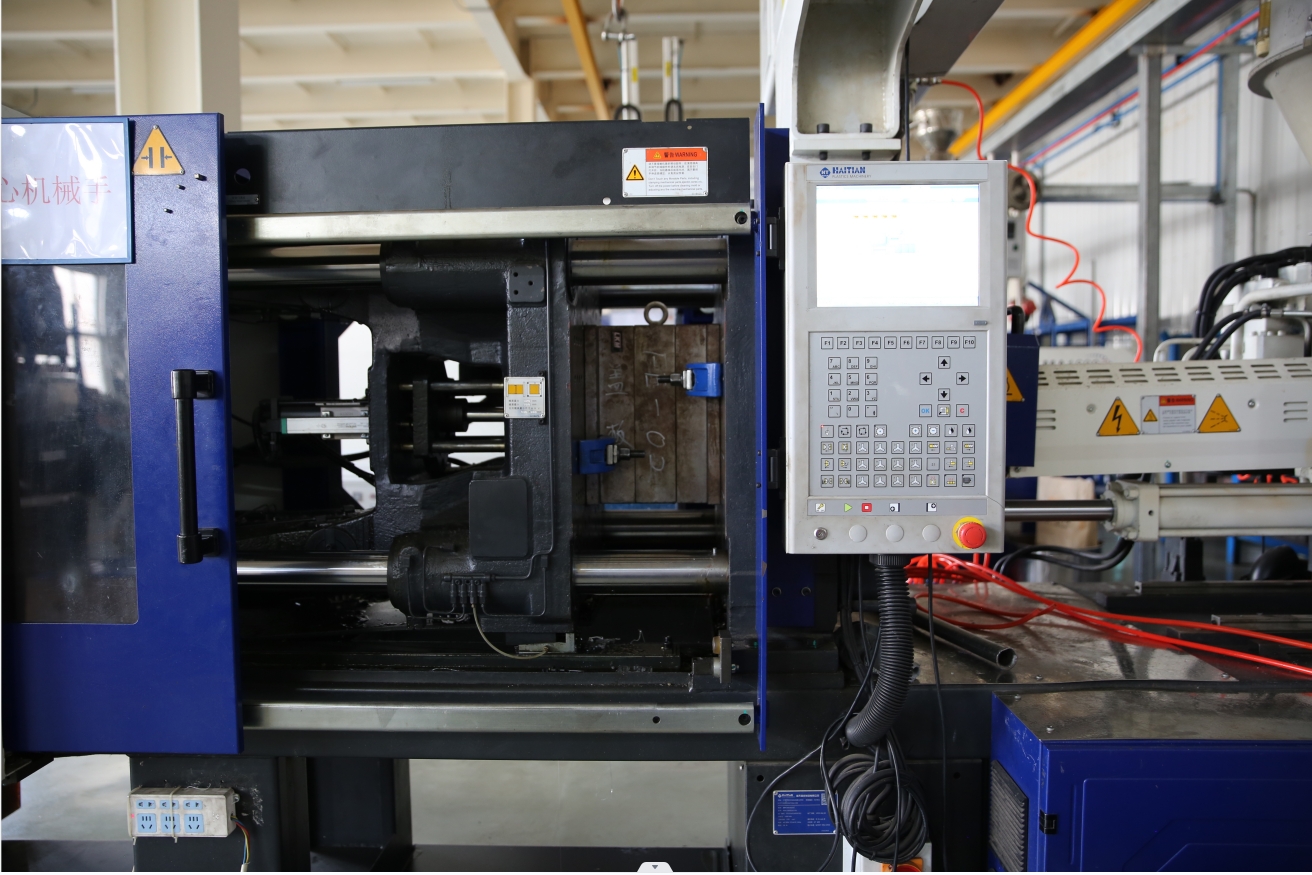

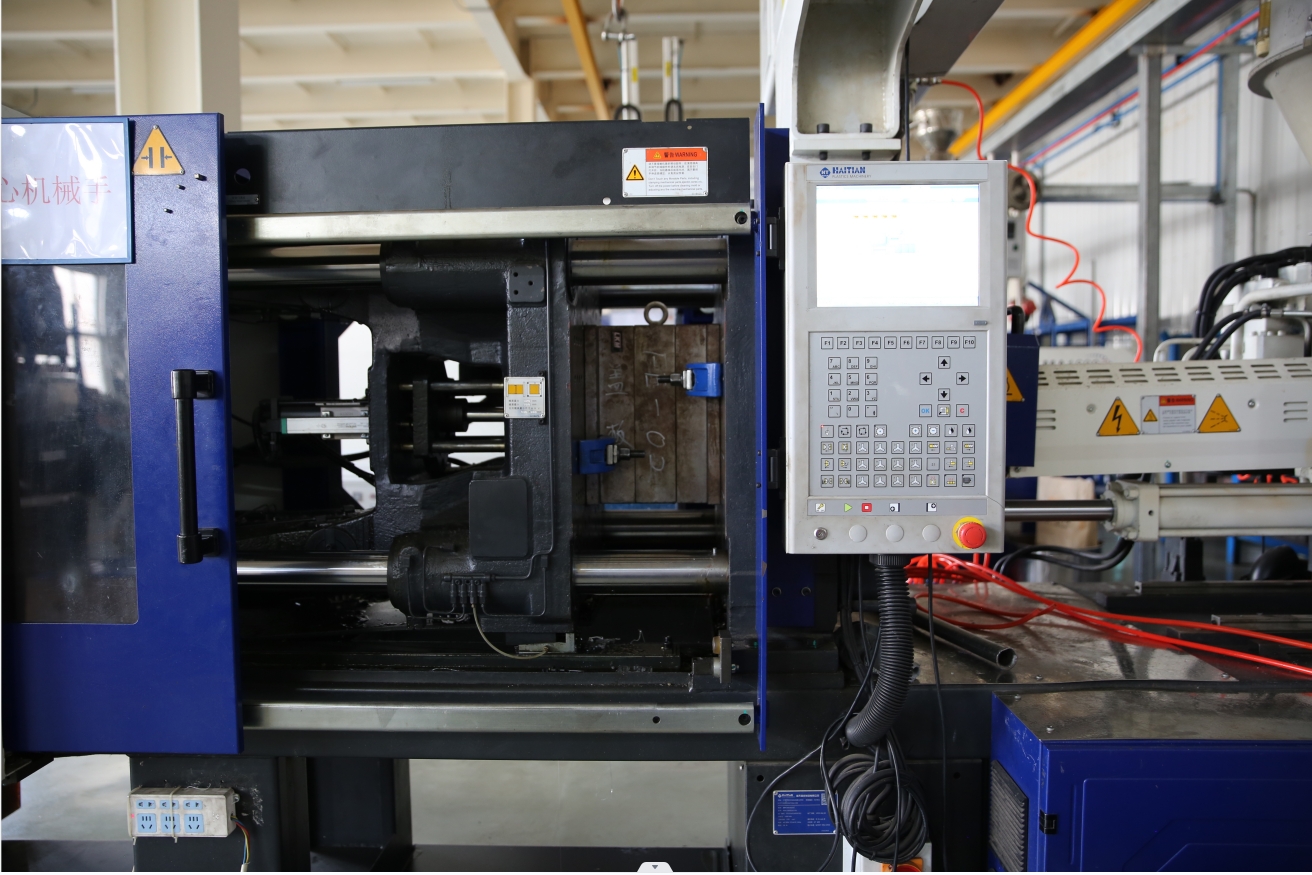

First, we need to understand what an injection mold is. In simple terms, injection mold is a tool used to make plastic parts, which can be melted plastic material injected into the mold, cooling to form the desired part shape. Automotive injection molds are specialized for the manufacture of automotive parts.

The process of automotive injection mold processing can be divided into the following steps:

1. Design stage: This is the first step of mold processing, according to the design drawings of auto parts, the use of professional CAD/CAM software for mold design and simulation. This stage needs to take into account the size of the mold, shape, cooling system and other factors to ensure that the mold can accurately replicate the shape of the auto parts.

2. Mold making stage: After the design is completed, it is necessary to use CNC machine tools and other equipment to accurately cut and carve the mold according to the requirements of the design drawings. This stage requires very delicate operation, as any small error can affect the quality of the final product.

3. Heat treatment stage: In order to improve the hardness and wear resistance of the mold, it is usually necessary to heat treat the mold. This stage needs to control the temperature and time to prevent mold deformation or damage.

4. Surface treatment stage: In order to improve the corrosion resistance and aesthetics of the mold, it is usually necessary to perform surface treatment on the mold, such as chrome plating, painting, etc. This stage needs to choose the appropriate treatment method to ensure the surface quality of the mold.

5. Inspection stage: After the mold processing is completed, it is necessary to carry out strict quality inspection, including size inspection, shape inspection, surface inspection, etc., to ensure that the quality of the mold meets the requirements.

Automotive injection mold processing is a complex and delicate work, it requires a high degree of professional knowledge and skills. However, it is precisely this kind of precision processing that can ensure the high quality and performance of automotive parts, so as to meet the high requirements of the automotive industry for safety, environmental protection, energy saving and other aspects. Therefore, the processing of automotive injection molds is not only a technical task, but also a social responsibility.

In modern industrial production, automotive injection mold processing is a crucial task. They are not only the basis for the production of auto parts, but also a key factor in ensuring product quality. So, how is the automobile injection mold processed? Let's go into this sophisticated world and explore the mysteries behind it.

First, we need to understand what an injection mold is. In simple terms, injection mold is a tool used to make plastic parts, which can be melted plastic material injected into the mold, cooling to form the desired part shape. Automotive injection molds are specialized for the manufacture of automotive parts.

The process of automotive injection mold processing can be divided into the following steps:

1. Design stage: This is the first step of mold processing, according to the design drawings of auto parts, the use of professional CAD/CAM software for mold design and simulation. This stage needs to take into account the size of the mold, shape, cooling system and other factors to ensure that the mold can accurately replicate the shape of the auto parts.

2. Mold making stage: After the design is completed, it is necessary to use CNC machine tools and other equipment to accurately cut and carve the mold according to the requirements of the design drawings. This stage requires very delicate operation, as any small error can affect the quality of the final product.

3. Heat treatment stage: In order to improve the hardness and wear resistance of the mold, it is usually necessary to heat treat the mold. This stage needs to control the temperature and time to prevent mold deformation or damage.

4. Surface treatment stage: In order to improve the corrosion resistance and aesthetics of the mold, it is usually necessary to perform surface treatment on the mold, such as chrome plating, painting, etc. This stage needs to choose the appropriate treatment method to ensure the surface quality of the mold.

5. Inspection stage: After the mold processing is completed, it is necessary to carry out strict quality inspection, including size inspection, shape inspection, surface inspection, etc., to ensure that the quality of the mold meets the requirements.

Automotive injection mold processing is a complex and delicate work, it requires a high degree of professional knowledge and skills. However, it is precisely this kind of precision processing that can ensure the high quality and performance of automotive parts, so as to meet the high requirements of the automotive industry for safety, environmental protection, energy saving and other aspects. Therefore, the processing of automotive injection molds is not only a technical task, but also a social responsibility.