Medical equipment transparent injection molding parts processing precautions

Release time:2023-12-11

Medical equipment transparent injection molding parts processing precautions

In many areas of the medical industry, the application of medical devices is undoubtedly crucial. In the manufacturing process of medical devices, the processing of transparent injection parts is an important link. However, this process is not easy and requires our attention to many details and precautions. This paper will deeply discuss the key links of transparent injection molding parts for medical devices, in order to provide some useful references for medical device manufacturers.

First of all, we need to make it clear that the quality of transparent injection parts is directly related to the performance and safety of medical devices. Therefore, we must be strict when choosing raw materials. High-quality transparent plastics such as polycarbonate (PC) or acrylic resin (PMMA) are ideal because they have good transparency, strength and wear resistance to meet the needs of medical devices.

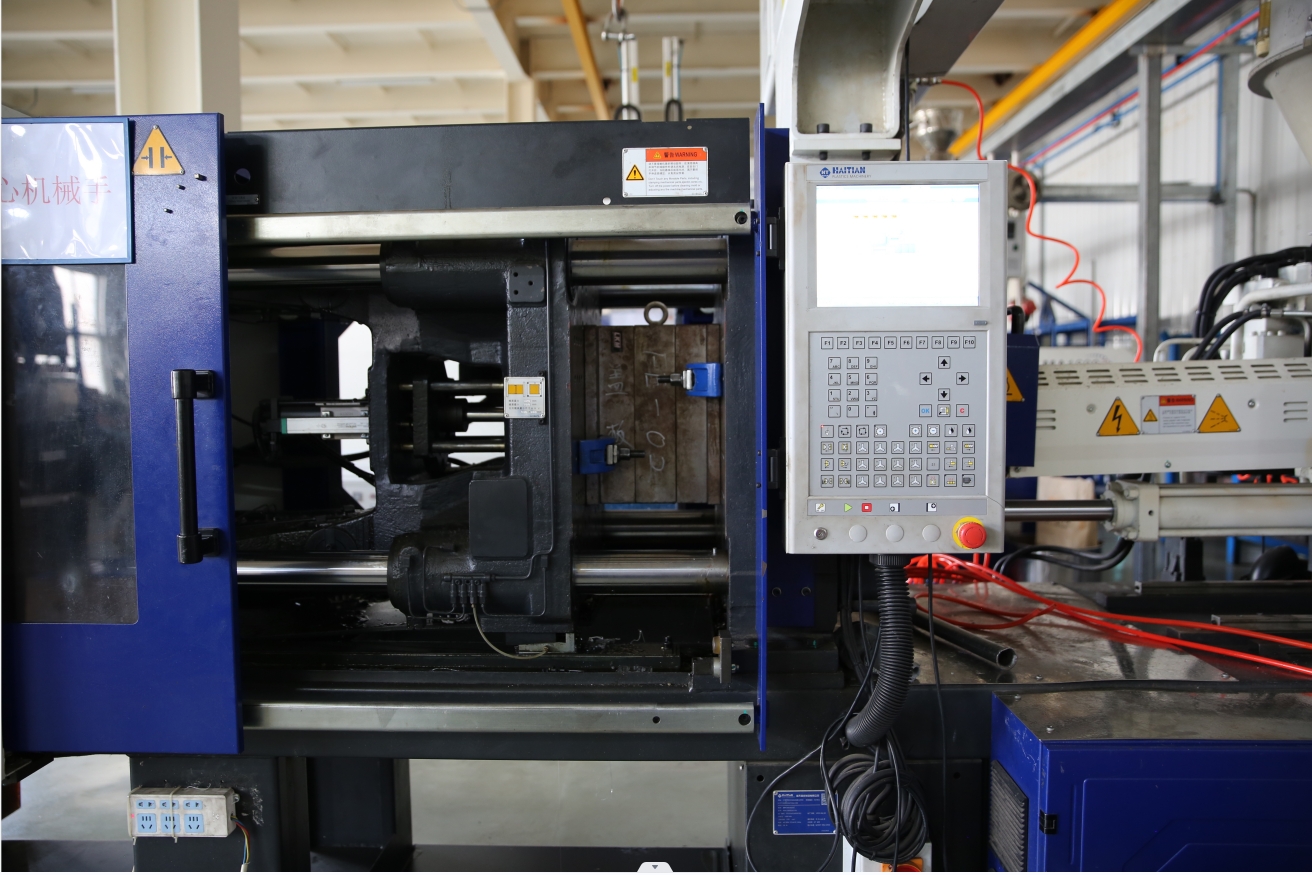

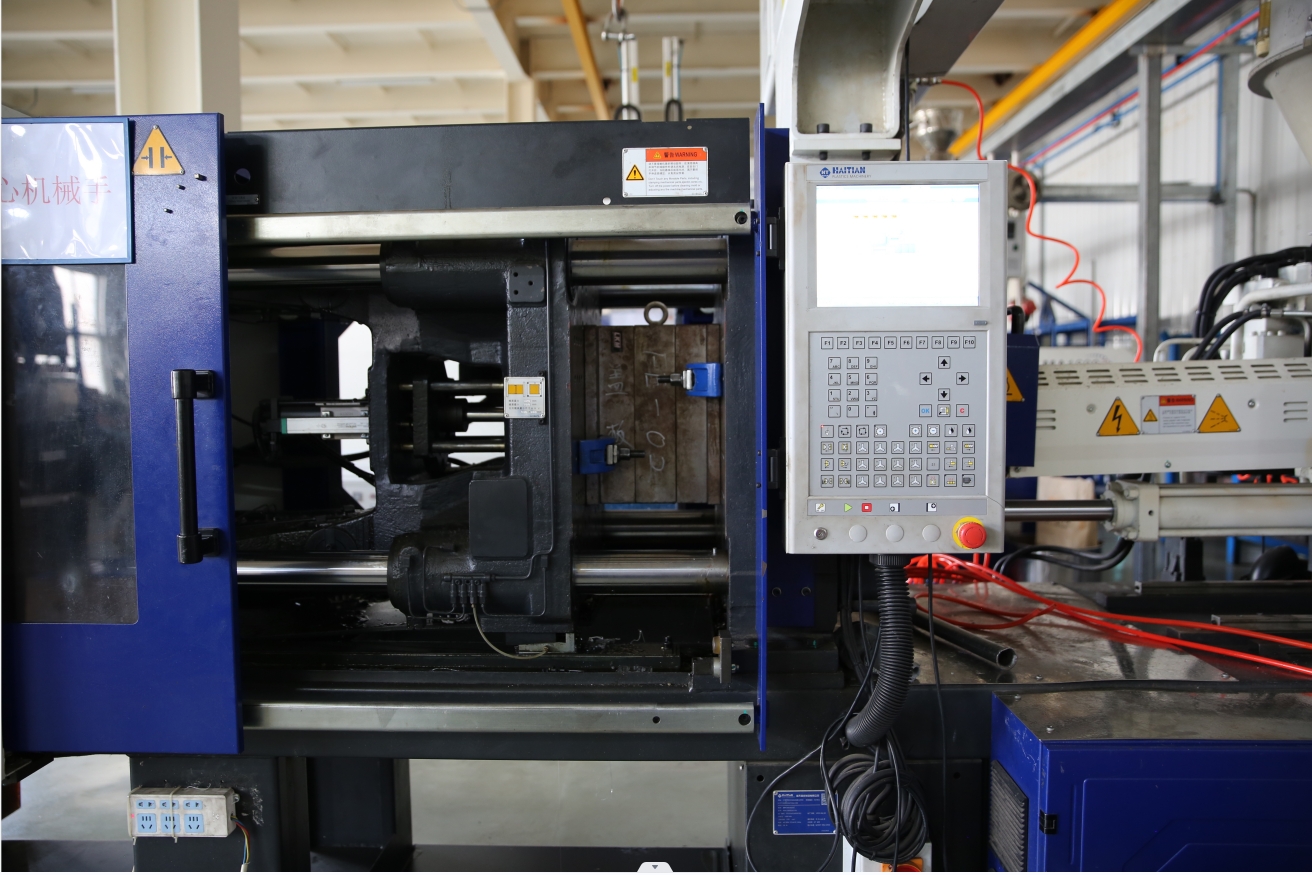

Secondly, the choice of injection molding process is also key. We need to choose the right injection molding machine and mold according to the shape, size and use of the product. At the same time, we also need to control the injection temperature, pressure and time to ensure the quality and performance of the product. In this process, we may need to conduct several trials and adjustments to achieve the best results.

In addition, we also need to pay attention to the post-processing of products. For example, we may need to perform cutting, edging, polishing and other processes to improve the appearance and performance of the product. In this process, we must ensure the accuracy and safety of the operation to avoid damage to the product.

Finally, we also need to carry out strict quality testing on the products. This includes testing the size, shape, color, transparency, strength, etc. of the product, as well as testing the performance and safety of the product. Only through strict quality testing can we ensure the quality of our products and meet the needs of medical devices.

In general, the processing of medical equipment transparent injection molding parts is a complex and important process that requires our attention to many details and precautions. Only in this way can we produce high-quality medical devices and contribute to the development of the medical industry.

In many areas of the medical industry, the application of medical devices is undoubtedly crucial. In the manufacturing process of medical devices, the processing of transparent injection parts is an important link. However, this process is not easy and requires our attention to many details and precautions. This paper will deeply discuss the key links of transparent injection molding parts for medical devices, in order to provide some useful references for medical device manufacturers.

First of all, we need to make it clear that the quality of transparent injection parts is directly related to the performance and safety of medical devices. Therefore, we must be strict when choosing raw materials. High-quality transparent plastics such as polycarbonate (PC) or acrylic resin (PMMA) are ideal because they have good transparency, strength and wear resistance to meet the needs of medical devices.

Secondly, the choice of injection molding process is also key. We need to choose the right injection molding machine and mold according to the shape, size and use of the product. At the same time, we also need to control the injection temperature, pressure and time to ensure the quality and performance of the product. In this process, we may need to conduct several trials and adjustments to achieve the best results.

In addition, we also need to pay attention to the post-processing of products. For example, we may need to perform cutting, edging, polishing and other processes to improve the appearance and performance of the product. In this process, we must ensure the accuracy and safety of the operation to avoid damage to the product.

Finally, we also need to carry out strict quality testing on the products. This includes testing the size, shape, color, transparency, strength, etc. of the product, as well as testing the performance and safety of the product. Only through strict quality testing can we ensure the quality of our products and meet the needs of medical devices.

In general, the processing of medical equipment transparent injection molding parts is a complex and important process that requires our attention to many details and precautions. Only in this way can we produce high-quality medical devices and contribute to the development of the medical industry.