Title:Auxiliary Switch Life Judgment in Electric Mechanisms

Release time:2023-12-05

Title:Auxiliary Switch Life Judgment in Electric Mechanisms

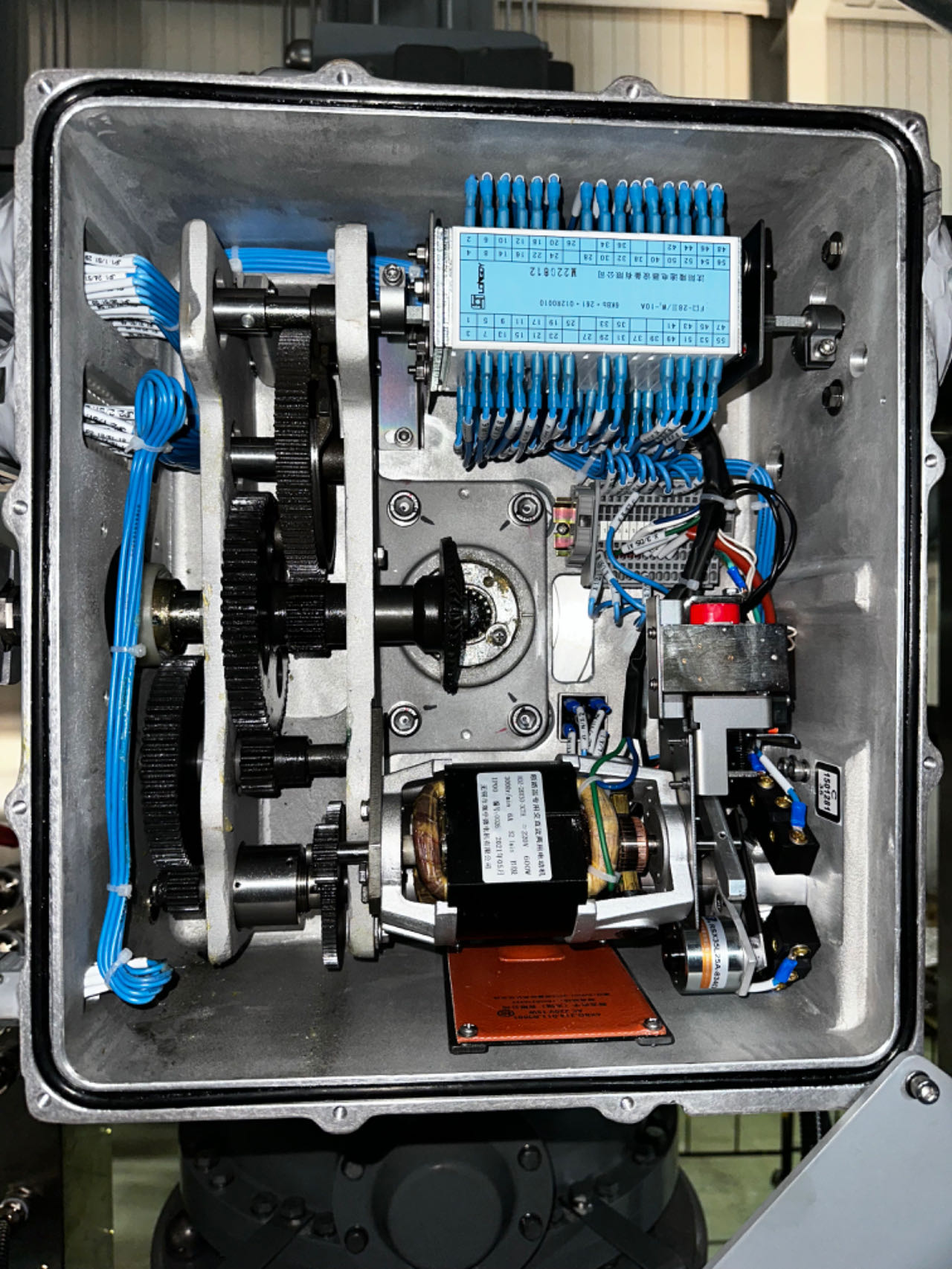

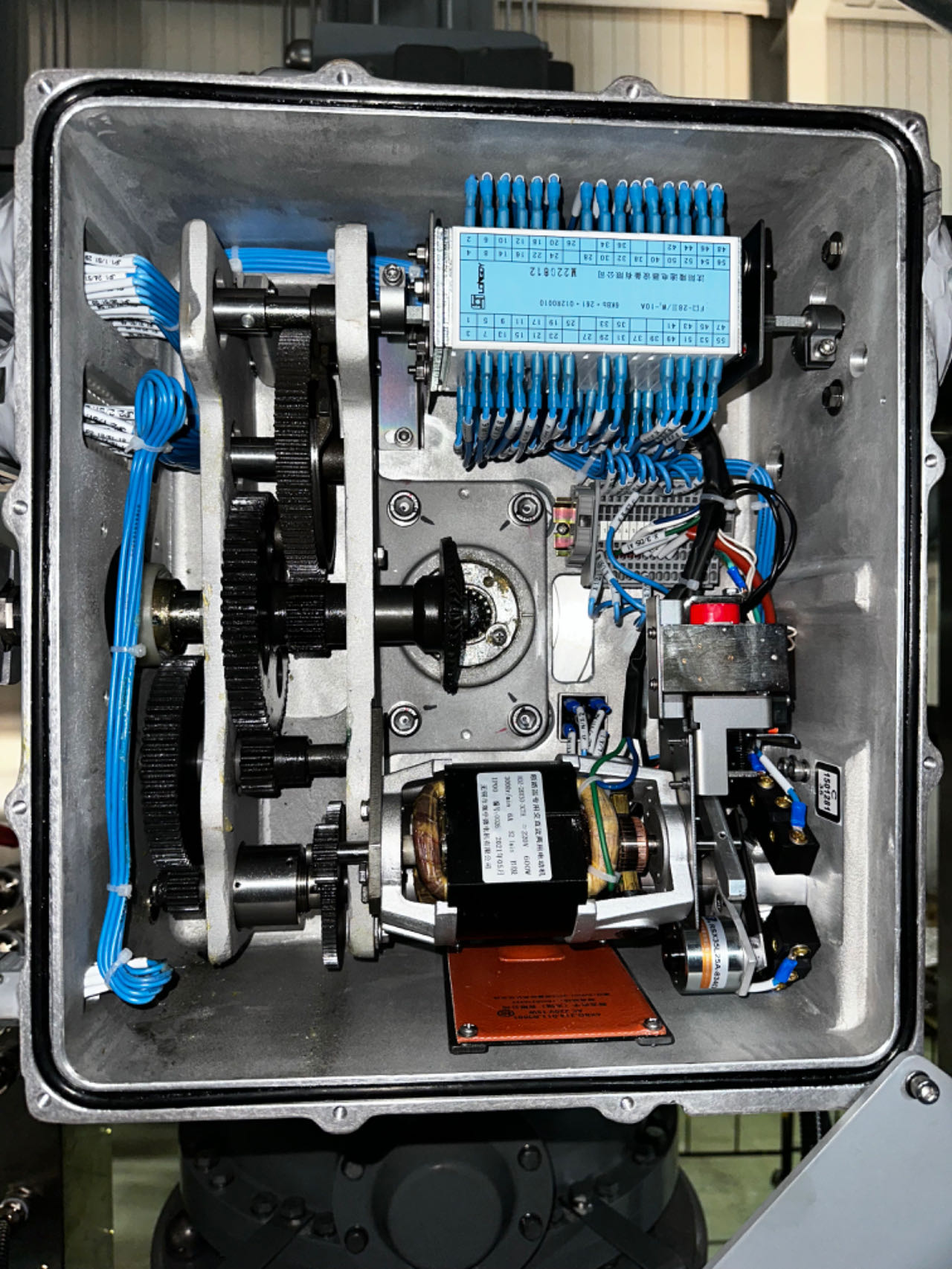

In modern industrial production, the application of motor mechanism is more and more extensive, and its stability and reliability are directly related to production efficiency and safety. In the electric mechanism, the auxiliary switch, as an important component, has a direct effect on the working state of the whole equipment. So, how to judge the life of the auxiliary switch in the electric mechanism? This article will discuss from the following aspects.

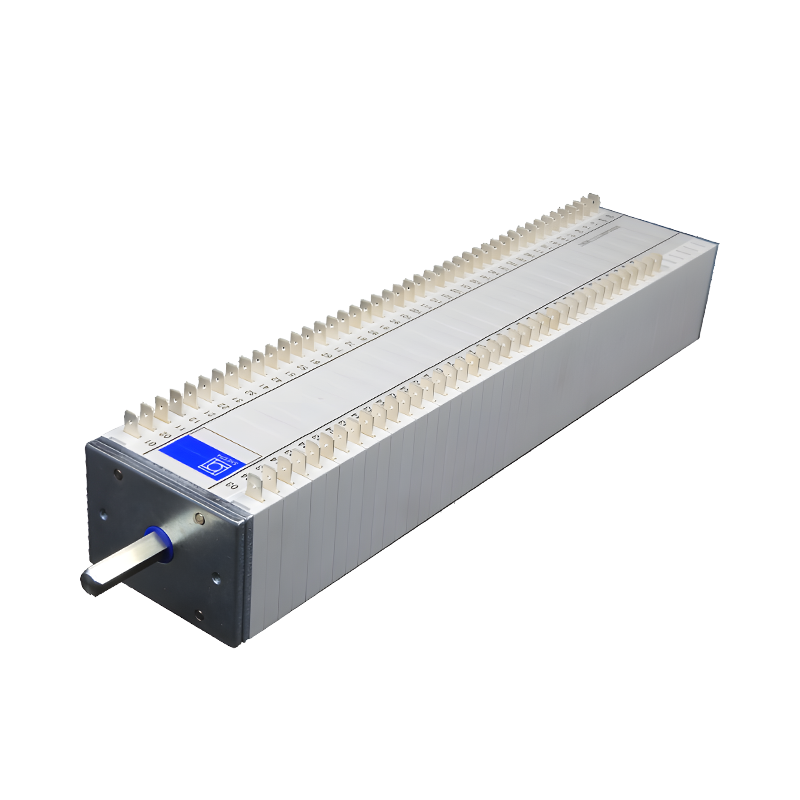

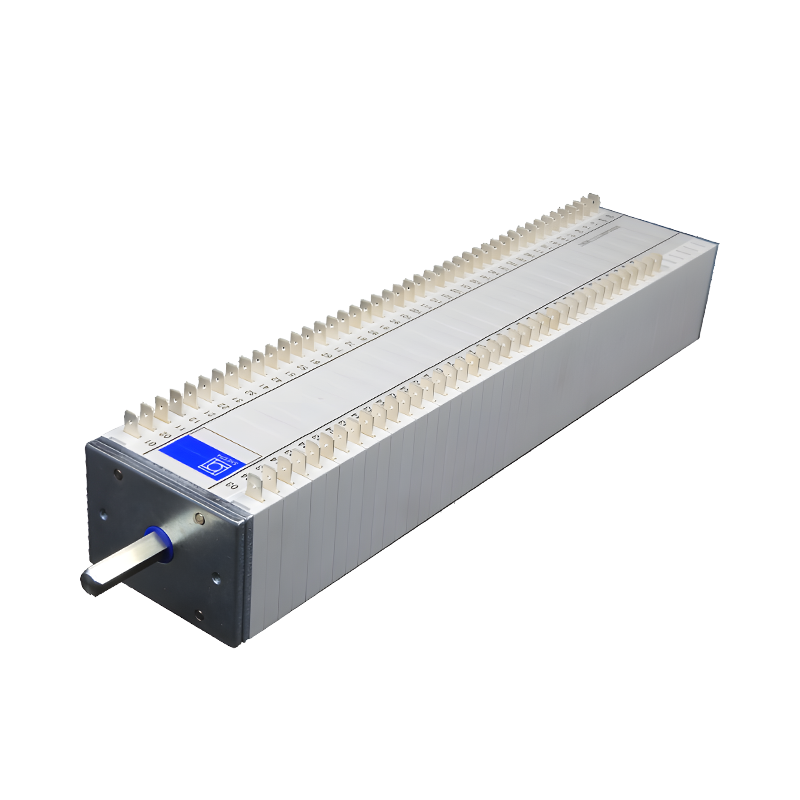

First, we need to understand the basic working principle of the auxiliary switch. The auxiliary switch is an electrical component used to control the on-off of the circuit. Its main function is to protect and control the circuit after the main switch is actuated. In electric mechanisms, auxiliary switches are commonly used to control the starting, stopping, forward and reverse operation of the motor. Therefore, the life of the auxiliary switch is closely related to its operating environment, operating frequency, load current, and other factors.

Secondly, we can judge the service life of the auxiliary switch through the following aspects:

1. Observe the operating status of the switch: During daily use, we need to pay close attention to the operating status of the auxiliary switch. If the switch is found to have poor contact, ablation, deformation and other phenomena, it indicates that the switch has approached or reached the service life limit and needs to be replaced in time.

2. Check the number of actions of the switch: the service life of the auxiliary switch is related to the number of actions. In general, the more times a switch is actuated, the shorter its life. Therefore, we need to check the number of times the switches are actuated periodically in order to find and replace the switches whose life has expired.

3. Measure the resistance of the switch: By measuring the resistance of the auxiliary switch, we can judge whether it is in normal working condition. If the resistance value is too large or too small, the switch may be faulty and needs to be repaired or replaced in a timely manner.

4. Refer to the service life data provided by the manufacturer: When purchasing auxiliary switches, the manufacturer usually provides certain service life data. We can judge the service life of the switch based on these data. It should be noted that the actual service life may be affected by factors such as the working environment and operating frequency, so it needs to be adjusted according to the actual situation.

Finally, in order to extend the service life of the auxiliary switch, we need to do the following:

1. Selection of reliable auxiliary switches: When purchasing auxiliary switches, we need to select products with reliable quality and stable performance to ensure the normal operation of the equipment.

2. Reasonable installation and use: When installing and using auxiliary switches, we need to follow relevant regulations and requirements to avoid damage to the switches due to improper installation or improper use.

3. Periodic inspection and maintenance: we need to check the operating status of the auxiliary switch regularly to find and deal with faults in time to extend its service life.

In a word, the life of the auxiliary switch in the electric mechanism needs to be considered comprehensively from many aspects. By observing the operating status of the switch, checking the number of actions, measuring the resistance value and referring to the service life data provided by the manufacturer, we can accurately judge the service life of the auxiliary switch. At the same time, doing a good job of installation, use and maintenance is also the key to extending the service life of the auxiliary switch.

In modern industrial production, the application of motor mechanism is more and more extensive, and its stability and reliability are directly related to production efficiency and safety. In the electric mechanism, the auxiliary switch, as an important component, has a direct effect on the working state of the whole equipment. So, how to judge the life of the auxiliary switch in the electric mechanism? This article will discuss from the following aspects.

First, we need to understand the basic working principle of the auxiliary switch. The auxiliary switch is an electrical component used to control the on-off of the circuit. Its main function is to protect and control the circuit after the main switch is actuated. In electric mechanisms, auxiliary switches are commonly used to control the starting, stopping, forward and reverse operation of the motor. Therefore, the life of the auxiliary switch is closely related to its operating environment, operating frequency, load current, and other factors.

Secondly, we can judge the service life of the auxiliary switch through the following aspects:

1. Observe the operating status of the switch: During daily use, we need to pay close attention to the operating status of the auxiliary switch. If the switch is found to have poor contact, ablation, deformation and other phenomena, it indicates that the switch has approached or reached the service life limit and needs to be replaced in time.

2. Check the number of actions of the switch: the service life of the auxiliary switch is related to the number of actions. In general, the more times a switch is actuated, the shorter its life. Therefore, we need to check the number of times the switches are actuated periodically in order to find and replace the switches whose life has expired.

3. Measure the resistance of the switch: By measuring the resistance of the auxiliary switch, we can judge whether it is in normal working condition. If the resistance value is too large or too small, the switch may be faulty and needs to be repaired or replaced in a timely manner.

4. Refer to the service life data provided by the manufacturer: When purchasing auxiliary switches, the manufacturer usually provides certain service life data. We can judge the service life of the switch based on these data. It should be noted that the actual service life may be affected by factors such as the working environment and operating frequency, so it needs to be adjusted according to the actual situation.

Finally, in order to extend the service life of the auxiliary switch, we need to do the following:

1. Selection of reliable auxiliary switches: When purchasing auxiliary switches, we need to select products with reliable quality and stable performance to ensure the normal operation of the equipment.

2. Reasonable installation and use: When installing and using auxiliary switches, we need to follow relevant regulations and requirements to avoid damage to the switches due to improper installation or improper use.

3. Periodic inspection and maintenance: we need to check the operating status of the auxiliary switch regularly to find and deal with faults in time to extend its service life.

In a word, the life of the auxiliary switch in the electric mechanism needs to be considered comprehensively from many aspects. By observing the operating status of the switch, checking the number of actions, measuring the resistance value and referring to the service life data provided by the manufacturer, we can accurately judge the service life of the auxiliary switch. At the same time, doing a good job of installation, use and maintenance is also the key to extending the service life of the auxiliary switch.