The key to automotive stamping parts processing: the importance of choosing the right stamping mold

Release time:2023-12-02

The key to automotive stamping parts processing: the importance of choosing the right stamping mold

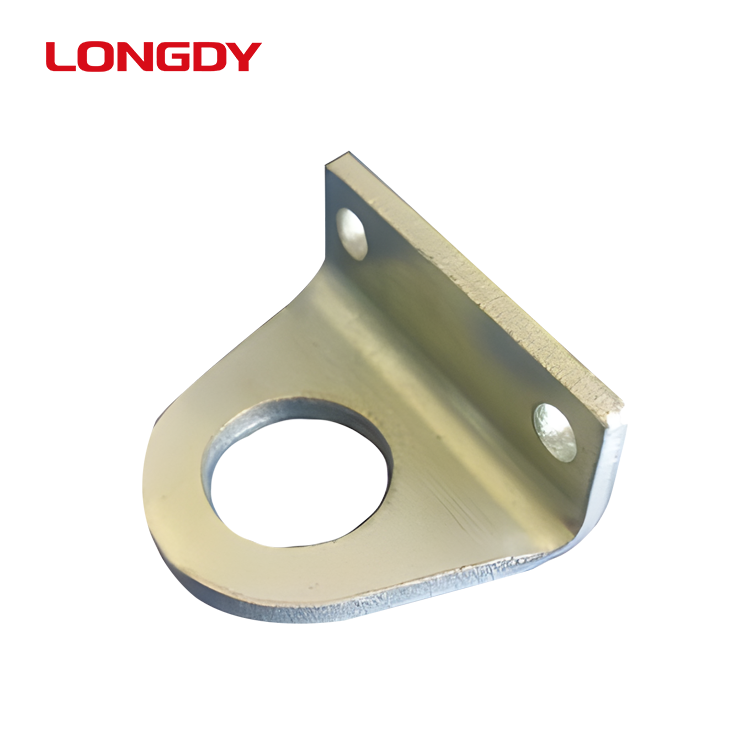

In the automobile manufacturing process, stamping parts are an indispensable component. The processing quality of stamping parts directly affects the safety and performance stability of the car. In order to ensure the quality and accuracy of stamping parts, it is crucial to choose the appropriate stamping mold.

First, the type of stamping die must match the shape and size of the stamped parts. Stamping parts of different shapes and sizes require different molds to complete the processing. If selected improperly, it may cause problems such as jamming and deformation during the processing of stamping parts, thereby affecting its quality and dimensional accuracy.

Secondly, the material of the stamping die is also an important factor affecting the processing quality of stamping parts. In general, the materials used in stamping molds should have sufficient hardness and wear resistance to ensure that the mold will not wear and deform during long-term use. Common stamping die materials include alloy tool steel, carbide, etc. Choosing materials suitable for stamping parts processing can improve the service life and processing efficiency of the stamping die.

In addition, the design of stamping molds is also a key factor in determining processing accuracy and efficiency. Properly designed stamping dies can better adapt to the shape and characteristics of stamped parts and effectively avoid deviations and distortions during processing. At the same time, reasonable design can also reduce the wear of stamping dies, improve stamping efficiency, and save production costs.

In short, choosing the right stamping die is crucial for automotive stamping parts processing. Only by fully considering the shape, size, material and design can we ensure the quality and accuracy of stamping parts processing and improve the safety and reliability of automotive products.

In the automobile manufacturing process, stamping parts are an indispensable component. The processing quality of stamping parts directly affects the safety and performance stability of the car. In order to ensure the quality and accuracy of stamping parts, it is crucial to choose the appropriate stamping mold.

First, the type of stamping die must match the shape and size of the stamped parts. Stamping parts of different shapes and sizes require different molds to complete the processing. If selected improperly, it may cause problems such as jamming and deformation during the processing of stamping parts, thereby affecting its quality and dimensional accuracy.

Secondly, the material of the stamping die is also an important factor affecting the processing quality of stamping parts. In general, the materials used in stamping molds should have sufficient hardness and wear resistance to ensure that the mold will not wear and deform during long-term use. Common stamping die materials include alloy tool steel, carbide, etc. Choosing materials suitable for stamping parts processing can improve the service life and processing efficiency of the stamping die.

In addition, the design of stamping molds is also a key factor in determining processing accuracy and efficiency. Properly designed stamping dies can better adapt to the shape and characteristics of stamped parts and effectively avoid deviations and distortions during processing. At the same time, reasonable design can also reduce the wear of stamping dies, improve stamping efficiency, and save production costs.

In short, choosing the right stamping die is crucial for automotive stamping parts processing. Only by fully considering the shape, size, material and design can we ensure the quality and accuracy of stamping parts processing and improve the safety and reliability of automotive products.