What is the requirement for the switching time of the auxiliary switch on the circuit breaker?

Release time:2023-11-06

What is the requirement for the switching time of the auxiliary switch on the circuit breaker?

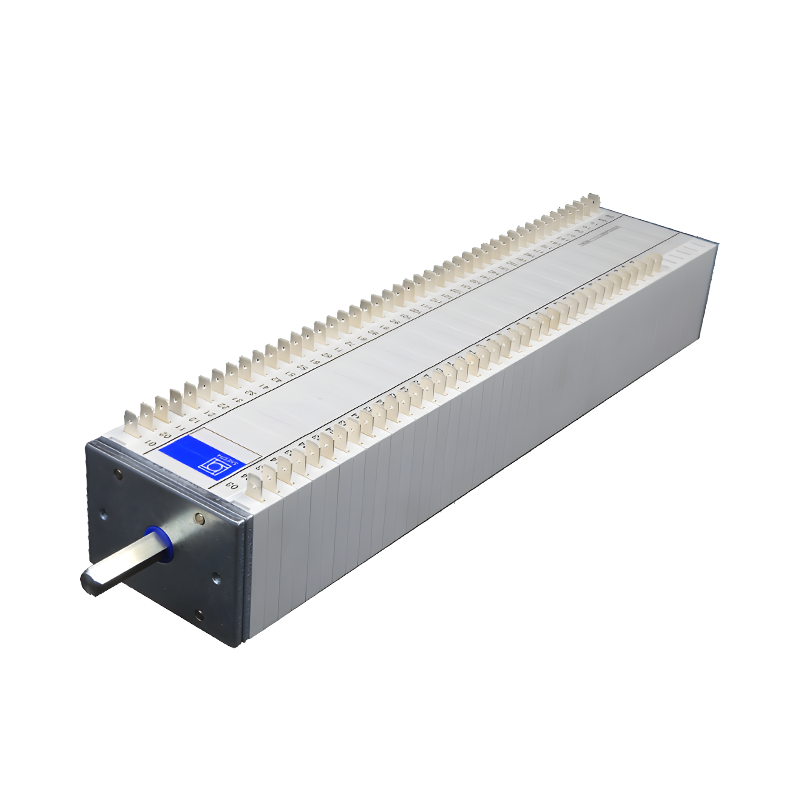

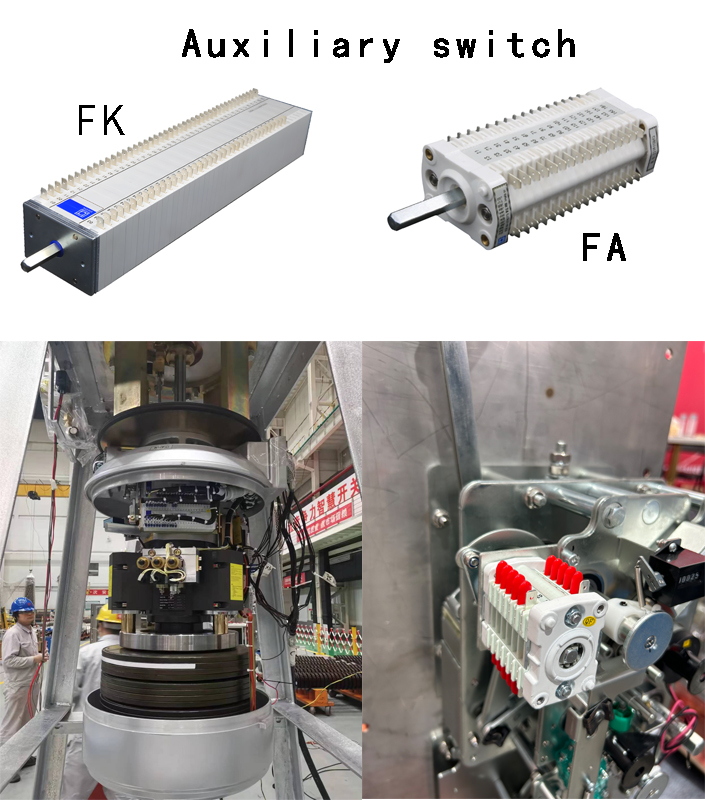

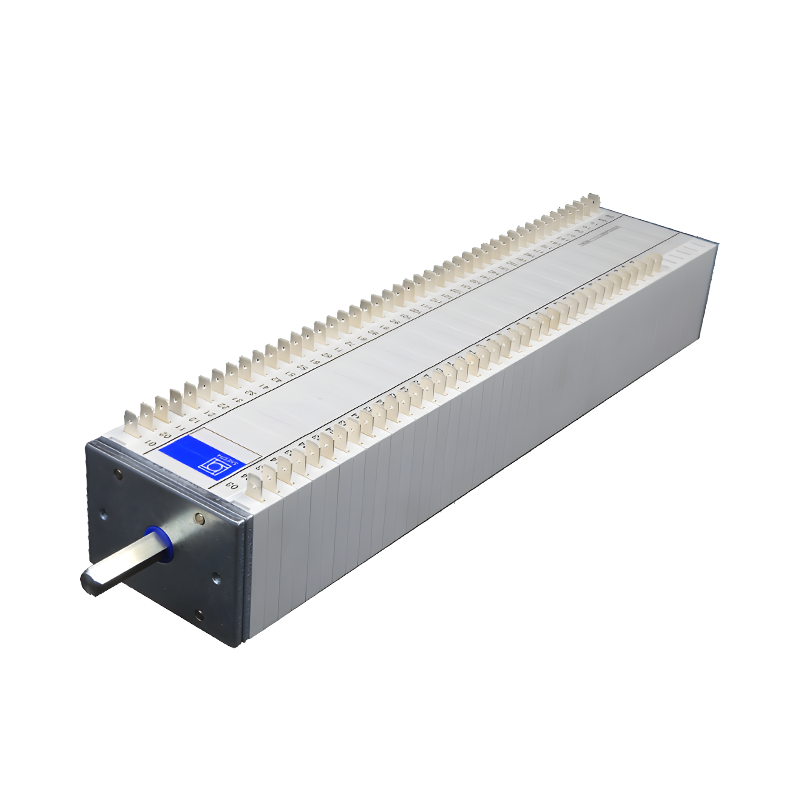

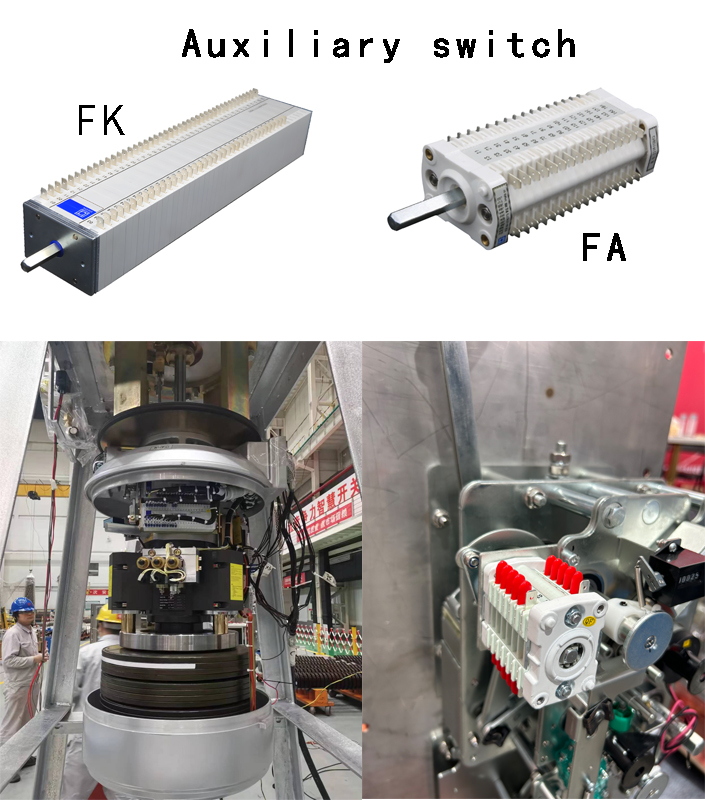

The auxiliary switch of the high-voltage circuit breaker is generally installed in the operating mechanism box. The mechanical device of the operating mechanism (high-voltage is generally a rotating device) drives the contact of the auxiliary switch to switch between split and close positions during the opening and closing operation process. During the switchover, the auxiliary switch cuts off the current supplied by the control circuit to the trip coil or the closing coil.

The position of the opening and closing electromagnets for different types of circuit breaker mechanisms is different. One of the main functions of the auxiliary switch is to cut off the opening or closing coil current during operation.

The switching time is set by the switch manufacturer, but will the switching time be too long to damage the opening and closing coil? The answer is no. Because this switching time is generally ms level, according to practical experience, when the coil current reaches its maximum current, and the duration is more than 10 s, the coil will have a certain amount of heating (different turn-off coils, the time is different, here is only the probability).

Consideration for setting switching time of auxiliary switchThere are auxiliary switches in operating mechanisms such as circuit breaker and isolating switch. High-voltage switches shall operate reliably and be prepared for the next reliable operation. During the closing action of the mechanism, the NC contact (normally closed node of auxiliary contact) for closing circuit of auxiliary switch shall be disconnected and the auxiliary contact for opening circuit shall be closed. These actions shall be reliably completed before the mechanism stops moving.

Therefore, (auxiliary switch switching) and main contact shall have time to cooperate, the specific time requirements shall be given by the manufacturer according to different models. The switch is generally completed within 10 milliseconds before the main contact is contacted. The opening is to complete the auxiliary contact contact conversion within 10 milliseconds after the main contact is separated. This is a very loose requirement, and some manufacturers specify how many percent of the main stroke curve to perform secondary contact conversion.

The auxiliary switch of the high-voltage circuit breaker is generally installed in the operating mechanism box. The mechanical device of the operating mechanism (high-voltage is generally a rotating device) drives the contact of the auxiliary switch to switch between split and close positions during the opening and closing operation process. During the switchover, the auxiliary switch cuts off the current supplied by the control circuit to the trip coil or the closing coil.

The position of the opening and closing electromagnets for different types of circuit breaker mechanisms is different. One of the main functions of the auxiliary switch is to cut off the opening or closing coil current during operation.

The switching time is set by the switch manufacturer, but will the switching time be too long to damage the opening and closing coil? The answer is no. Because this switching time is generally ms level, according to practical experience, when the coil current reaches its maximum current, and the duration is more than 10 s, the coil will have a certain amount of heating (different turn-off coils, the time is different, here is only the probability).

Consideration for setting switching time of auxiliary switchThere are auxiliary switches in operating mechanisms such as circuit breaker and isolating switch. High-voltage switches shall operate reliably and be prepared for the next reliable operation. During the closing action of the mechanism, the NC contact (normally closed node of auxiliary contact) for closing circuit of auxiliary switch shall be disconnected and the auxiliary contact for opening circuit shall be closed. These actions shall be reliably completed before the mechanism stops moving.

Therefore, (auxiliary switch switching) and main contact shall have time to cooperate, the specific time requirements shall be given by the manufacturer according to different models. The switch is generally completed within 10 milliseconds before the main contact is contacted. The opening is to complete the auxiliary contact contact conversion within 10 milliseconds after the main contact is separated. This is a very loose requirement, and some manufacturers specify how many percent of the main stroke curve to perform secondary contact conversion.