Why do slow-speed mechanisms need to use auxiliary switches?

Release time:2023-10-20

Why do slow-speed mechanisms need to use auxiliary switches?

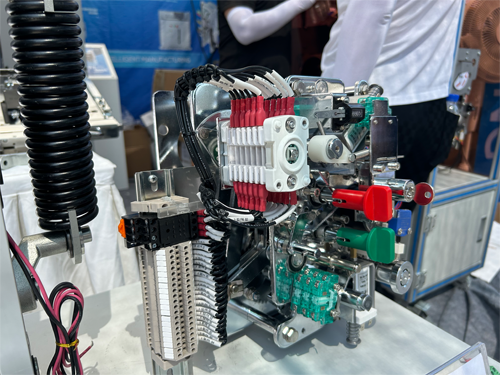

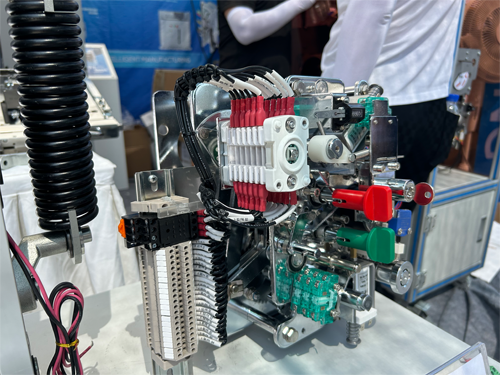

The slow speed mechanism refers to a component in construction machinery, mainly used to control the speed of mechanical movement. Under some specific work requirements, the role of slow mechanisms is particularly important. In order to better play the role of the slow-speed mechanism, the use of auxiliary switches is also very necessary.

First, the use of slow-speed mechanisms can help achieve precise control of mechanical movements. By adjusting the parameters of the slow mechanism, the speed and motion trajectory of the machine can be effectively controlled. The auxiliary switch is one of the key devices in controlling this process. The function of the auxiliary switch is to cut off the circuit in time when the machine reaches the designated position and stop the machine from continuing to move. In this way, not only can the safe operation of the machinery be ensured, but the working efficiency and accuracy of the machinery can also be controlled more accurately.

Secondly, the use of slow mechanisms can improve work efficiency. When the machine needs to work at a specific position, the slow-speed mechanism can make the machine slowly move to the target position by appropriately adjusting the speed. The setting of the auxiliary switch can detect the position information of the machine in time and stop further movement of the machine after reaching the target position. In this way, it can not only improve the working efficiency of machinery, but also reduce manual intervention and improve the degree of automation of work.

In addition, the use of slow-speed mechanisms can also extend the service life of the machinery. Due to the characteristics of slow motion, the friction and wear of machinery during work will be relatively reduced. At the same time, the control capability of the slow-speed mechanism also makes the machinery work more smoothly and reduces mechanical vibration and impact. The function of the auxiliary switch is to stop the mechanical movement in time when an abnormality occurs in the machinery to avoid further damage. In this way, the service life of the machinery can be effectively extended and the cost of repair and replacement can be reduced.

In summary, the use of auxiliary switches in slow-speed mechanisms has multiple advantages. Through the control of the auxiliary switch, the function of the slow-speed mechanism can be better realized, the working efficiency and accuracy of the machinery can be improved, and the service life of the machinery can be extended. Therefore, for users of slow-speed mechanisms, it is very necessary to use auxiliary switches.

The slow speed mechanism refers to a component in construction machinery, mainly used to control the speed of mechanical movement. Under some specific work requirements, the role of slow mechanisms is particularly important. In order to better play the role of the slow-speed mechanism, the use of auxiliary switches is also very necessary.

First, the use of slow-speed mechanisms can help achieve precise control of mechanical movements. By adjusting the parameters of the slow mechanism, the speed and motion trajectory of the machine can be effectively controlled. The auxiliary switch is one of the key devices in controlling this process. The function of the auxiliary switch is to cut off the circuit in time when the machine reaches the designated position and stop the machine from continuing to move. In this way, not only can the safe operation of the machinery be ensured, but the working efficiency and accuracy of the machinery can also be controlled more accurately.

Secondly, the use of slow mechanisms can improve work efficiency. When the machine needs to work at a specific position, the slow-speed mechanism can make the machine slowly move to the target position by appropriately adjusting the speed. The setting of the auxiliary switch can detect the position information of the machine in time and stop further movement of the machine after reaching the target position. In this way, it can not only improve the working efficiency of machinery, but also reduce manual intervention and improve the degree of automation of work.

In addition, the use of slow-speed mechanisms can also extend the service life of the machinery. Due to the characteristics of slow motion, the friction and wear of machinery during work will be relatively reduced. At the same time, the control capability of the slow-speed mechanism also makes the machinery work more smoothly and reduces mechanical vibration and impact. The function of the auxiliary switch is to stop the mechanical movement in time when an abnormality occurs in the machinery to avoid further damage. In this way, the service life of the machinery can be effectively extended and the cost of repair and replacement can be reduced.

In summary, the use of auxiliary switches in slow-speed mechanisms has multiple advantages. Through the control of the auxiliary switch, the function of the slow-speed mechanism can be better realized, the working efficiency and accuracy of the machinery can be improved, and the service life of the machinery can be extended. Therefore, for users of slow-speed mechanisms, it is very necessary to use auxiliary switches.